- Home Page

- Company Profile

-

Our Products

- Hydro Jetting Machine

- 1000 Bar 10000 PSI Electric Pressure Washer

- PressureJet Hydro Jetting Pump

- Hydro Jetting System

- Hydro Jetting Machine PressureJet

- PressureJet Hydro Jet Cleaning Machine

- Hydro Jetting Machines

- 20000 PSI Hydro Jetting Machine

- High Pressure Hydro Jetting Equipment

- High Pressure Hydro Jetting Machine

- Hydro Jetting Machine

- Hydro Jetting Equipment

- Hydro Blasting Machine

- 20K Hydroblaster Semi-Automatic Hydroblaster 20 K

- Pressure Jet Hydro Blasting Equipment

- 10000 PSI Hydro Blaster Semi-Automatic Hydro Blaster 10000 PSI

- 10K Water Blaster Semi-Automatic Water Blaster 10 K

- High Pressure Hydro Blasting System

- Pressure Jet Semi-Automatic Hydro Blasting Equipment

- Pressure Jet 3 Phase High Pressure Water Blaster

- 3 Phase Pumps 20000 PSI Pressure Washer

- Water Jet Cleaner

- Hydro Test Pump

- PressureJet Brass, S.s High Pressure Hydrotest Pump (Hydrostatic Test ) , Max Flow Rate: 197

- Stainless Steel Hydro Test Pump

- High Pressure Hydro Test Pump

- Motorized Hydro Test Pump

- Triplex Plunger Hydro Test Pump

- High Pressure Hydrostatic Test Pump

- Hydrostatic Pressure Testing Pump

- Diesel Driven Hydro Test Pump

- High Pressure Hydro Test Pump Unit

- Triplex Plunger Pumps

- Sewer Jetting Pump

- PressureJet ES Series Sewer Jetting Pump Max Flow Rate 412 Lpm

- PressureJet EM Series Sewer Jetting Pump Max Flow Rate 267 Lpm

- VA Series Sewer Jetting Pump Max Flow Rate 170 Lpm

- EA Series Sewer Jetting Pump Max Flow Rate 100 Lpm

- HW Series - Sewer Jetting Pump

- EA Series Sewer Jetting Pump Max Flow Rate 155 LPM

- Pressure Washer

- Jet Cleaners

- Water Blasting Machine

- High Pressure Water Jet Cleaner

- HIGH PRESSURE RECIPROCATING PUMPS

- Hydro Jetting Machine

- Extra Links

- Contact Us

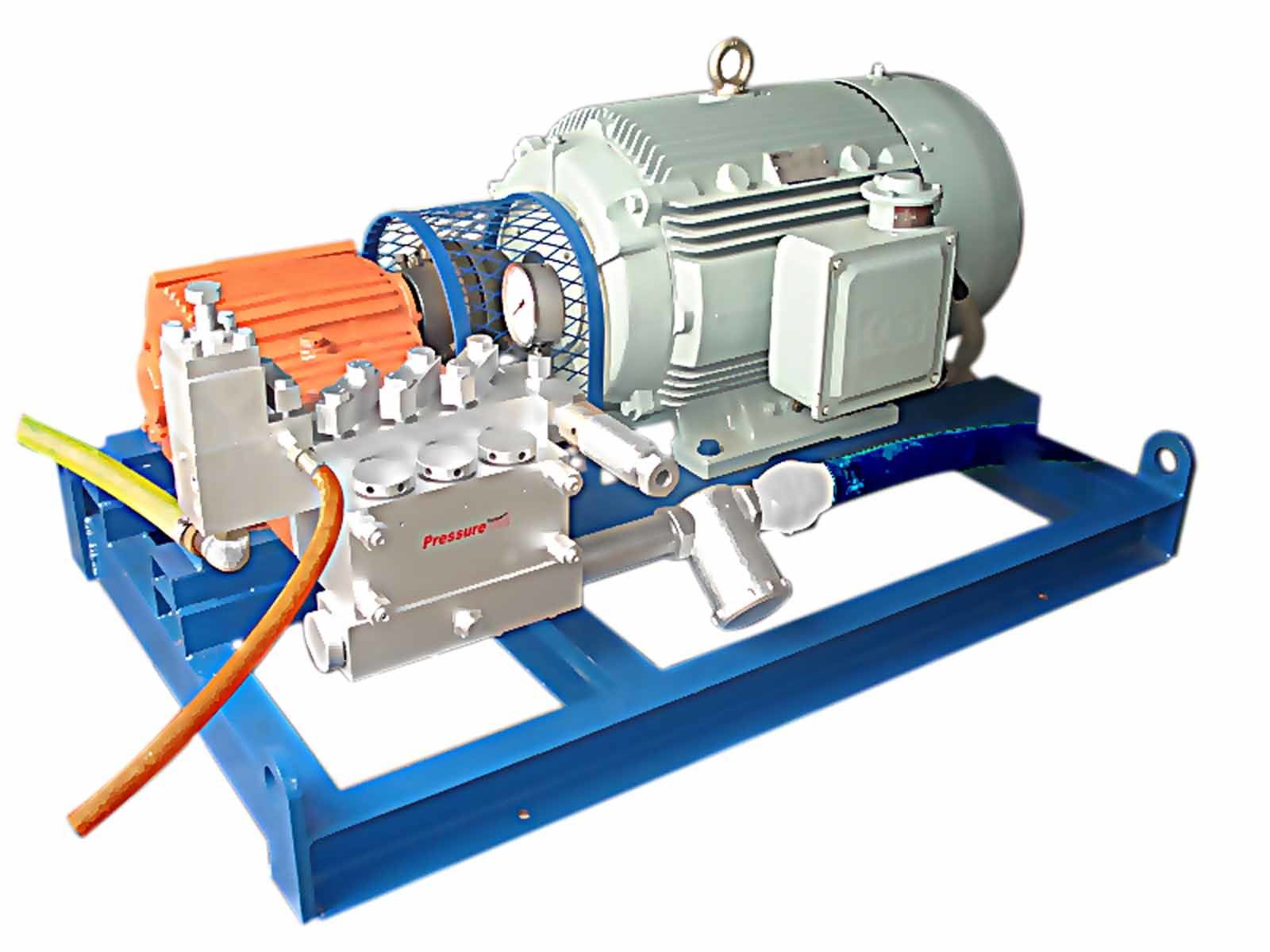

20000 PSI Hydro Jetting Machine

Price 200000.00 INR/ Piece

MOQ : 1 Unit

20000 PSI Hydro Jetting Machine Specification

- Usage

- Hydro Blasting , Hydro Jetting , Hydro Test

- Material

- Metal

- Type

- High Pressure Cleaner

- Condition

- New

- Size

- 1286*641*451

- Fuel Type

- Electric

- Height

- 451 Millimeter (mm)

- Use

- Container / Bottle Cleaning

- Cleaning Process

- Cold Water Cleaning

- Weight

- Approx weight of bare pump: 410 Kilograms (kg)

- Color

- Blue, Brown

- Cleaning Type

- High Pressure Cleaner

- Length

- 1286 Millimeter (mm)

- Width

- 641 Millimeter (mm)

- Voltage

- 415 Volt (v)

20000 PSI Hydro Jetting Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Nhava Sheva ( Mumbai ) , Pipavav , Kandla

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 3 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box type packing

- Main Export Market(s)

- Australia, Western Europe, Middle East, Central America, Africa, South America, Asia, Eastern Europe, North America

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About 20000 PSI Hydro Jetting Machine

With huge market knowledge and expertise, we are offering our valued customers with economical and reliable 20000 PSI Hydro Jetting Machine. Under this service, we include attacking the surface of a material with different types of shots. This is mainly completed to eliminate something on the surface like scale. We are best renowned for requisite workforce and facilities which allows us to take the work of this service with utmost precision. Further, clients can take benefits of this 20000 PSI Hydro Jetting Machine at affordable charges.Product Details:

|

Accessories Option |

Tube Cleaning Nozzle, Tube Cleaning Lance, Foot Operated Valve, Safety Valve, PRV Etc... |

|

Brand |

PressureJet |

|

Driver Type |

Electric Motor Driven, Diesel engine Driven |

|

Mounting Option |

Skid Mounted, Trolley Mounted |

|

Suitable For |

Tube cleaning - Heavy, hard scale and long length tubes |

|

Pressure Range in Bar |

250 bar to 1400 bar |

|

Portable |

Yes |

|

Phase |

3 Phase Pumps |

|

Packaging Type |

Box Type Packaging |

|

Media |

Pure Water |

|

Flow Rate Range in LPM |

15 LPM to 72 LPM |

|

Condition |

New |

|

Body Material |

Cast Iron |

|

Automatic Grade |

Semi-Automatic |

Powerful Performance for Industrial Cleaning

Designed for high-pressure applications, this machine delivers a formidable 20000 PSI and a steady flow rate of 30 lpm. Its metal construction and mechanical seals ensure long-lasting performance, making it an essential asset for rigorous cleaning tasks.

Versatile Applications Across Industries

Engineered for multiple uses, this hydro jetting machine is suitable for hydro blasting, hydro testing, and both container and bottle cleaning. Trusted by distributors, service providers, and manufacturers, it meets the diverse requirements of industrial cleaning challenges.

Efficient and Convenient Operation

With cold water cleaning capability and an electric fuel type, this unit offers efficient maintenance and user-friendly operation. Its compact size and mobility make it ideal for on-site cleaning and industrial facilities where space and efficiency matter.

FAQ's of 20000 PSI Hydro Jetting Machine:

Q: How does the 20000 PSI Hydro Jetting Machine operate?

A: This hydro jetting machine uses an electric-powered piston pump to generate high-pressure water jets of up to 20000 PSI. Combined with a flow rate of 30 lpm, it effectively removes stubborn dirt, scale, and contaminants in industrial settings.Q: What types of cleaning processes is this machine suitable for?

A: It is designed primarily for hydro jetting, hydro blasting, and hydro testing, as well as cleaning containers and bottles. It uses cold water cleaning, making it safe for use on a wide range of surfaces and materials.Q: When should I use a hydro jetting machine like this one?

A: You should use this high-pressure cleaner for heavy-duty cleaning tasks that require intense pressure to remove tough residues, such as in industrial facilities, manufacturing plants, or container depots.Q: Where can the 20000 PSI Hydro Jetting Machine be used?

A: This machine is ideal for use in industrial environments across India, including manufacturing facilities, service centers, and sites that require effective cleaning solutions for equipment, containers, and machinery.Q: What is the process for using this machine for container cleaning?

A: Set up the machine near the area to be cleaned, connect it to an appropriate power supply and water source, and direct the high-pressure jet onto the surface of the container or bottle to remove debris, scale, or contaminants effectively.Q: What are the major benefits of using this high-pressure cleaning machine?

A: The primary advantages include superior cleaning efficiency, reduced downtime through fast and thorough cleaning, and robust construction that maintains reliability in intense working environments.Q: Is the machine suitable for continuous use, and what maintenance is needed?

A: Yes, the machine is built for demanding use. Routine maintenance involves checking the mechanical seals, cleaning filters, and ensuring electric connections are secure to maximize lifespan and prevent unexpected breakdowns.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Hydro Jetting Machine Category

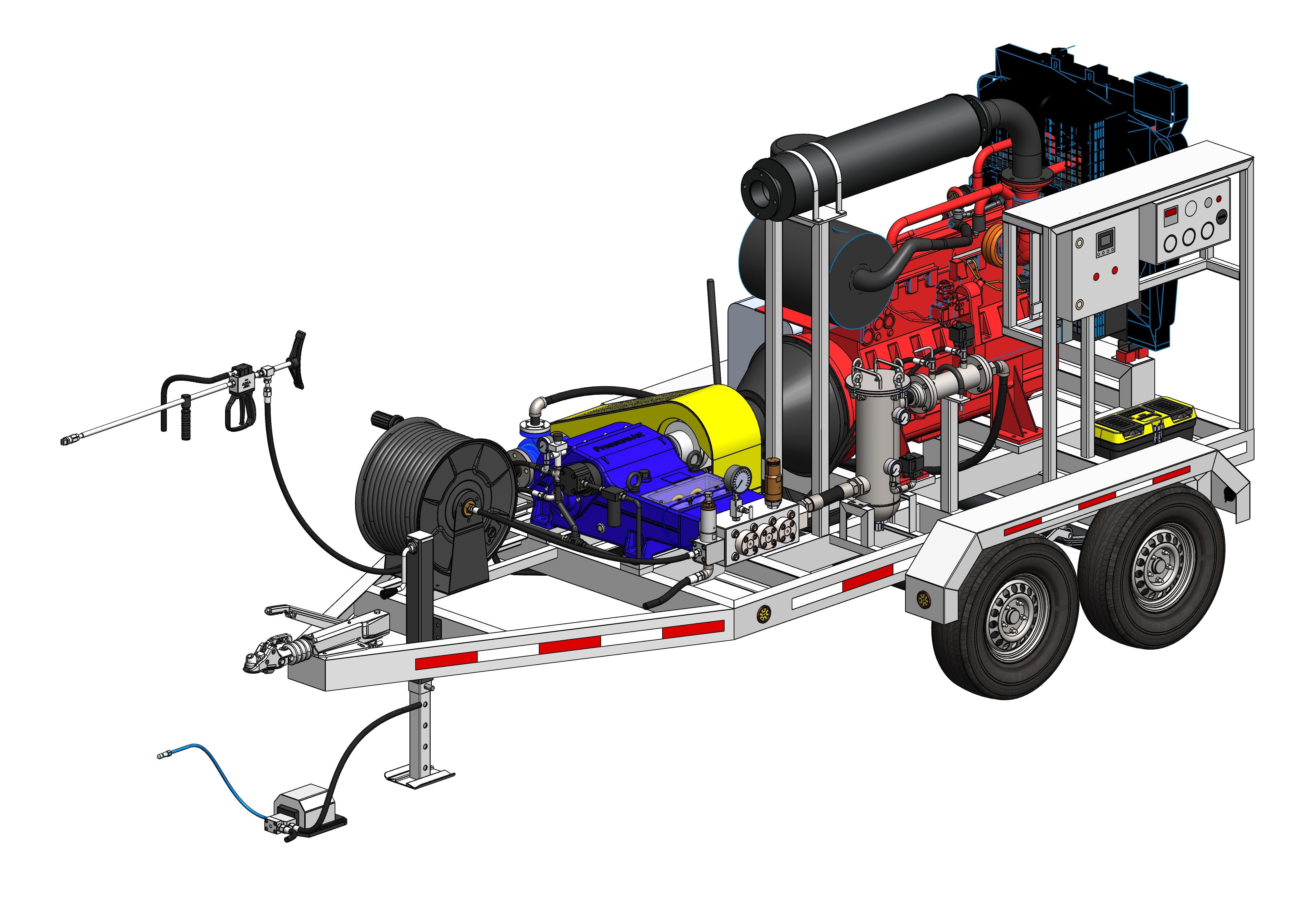

Hydro Jetting Machine

Price 1000000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Blue

Usage : General Cleaning , Boiler Tube Cleaning , Evaporator Tube Cleaning , External Cleaning etc.

Fuel Type : Diesel

Condition : New

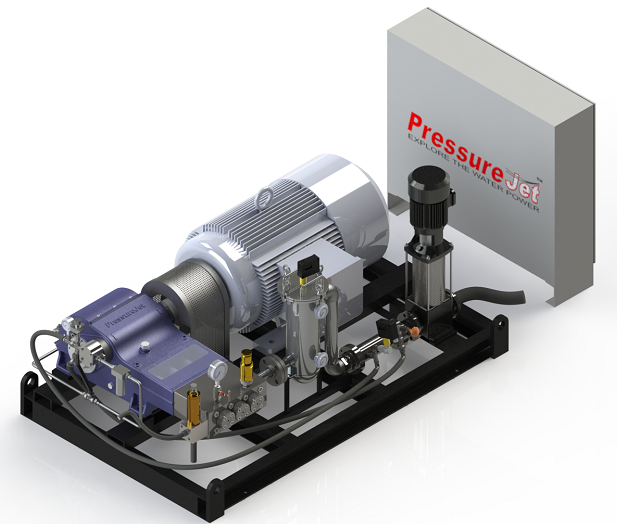

High Pressure Hydro Jetting Equipment

Price 1540000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Blue

Usage : Calindra Cleaning, Boiler Tube Cleaning , Evaporator Tube Cleaning , Internal Tank Cleaning etc.

Fuel Type : Electric

Condition : New

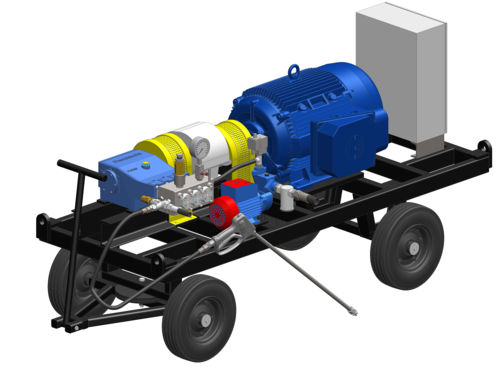

Hydro Jetting Machine PressureJet

Price 560000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Blue

Usage : General Cleaning , Boiler Tube Cleaning , Evaporator Tube Cleaning , External Cleaning etc.

Fuel Type : Electric

Condition : New

PressureJet Hydro Jet Cleaning Machine

Price 1400000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Blue

Usage : Calindra Cleaning , Boiler Tube Cleaning , Condenser Tube Cleaning , Internal Cleaning etc.

Fuel Type : Electric

Condition : New

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free