- Home Page

- Company Profile

-

Our Products

- Hydro Jetting Machine

- 1000 Bar 10000 PSI Electric Pressure Washer

- PressureJet Hydro Jetting Pump

- Hydro Jetting System

- Hydro Jetting Machine PressureJet

- PressureJet Hydro Jet Cleaning Machine

- Hydro Jetting Machines

- 20000 PSI Hydro Jetting Machine

- High Pressure Hydro Jetting Equipment

- High Pressure Hydro Jetting Machine

- Hydro Jetting Machine

- Hydro Jetting Equipment

- Hydro Blasting Machine

- 20K Hydroblaster Semi-Automatic Hydroblaster 20 K

- Pressure Jet Hydro Blasting Equipment

- 10000 PSI Hydro Blaster Semi-Automatic Hydro Blaster 10000 PSI

- 10K Water Blaster Semi-Automatic Water Blaster 10 K

- High Pressure Hydro Blasting System

- Pressure Jet Semi-Automatic Hydro Blasting Equipment

- Pressure Jet 3 Phase High Pressure Water Blaster

- 3 Phase Pumps 20000 PSI Pressure Washer

- Water Jet Cleaner

- Hydro Test Pump

- PressureJet Brass, S.s High Pressure Hydrotest Pump (Hydrostatic Test ) , Max Flow Rate: 197

- Stainless Steel Hydro Test Pump

- High Pressure Hydro Test Pump

- Motorized Hydro Test Pump

- Triplex Plunger Hydro Test Pump

- High Pressure Hydrostatic Test Pump

- Hydrostatic Pressure Testing Pump

- Diesel Driven Hydro Test Pump

- High Pressure Hydro Test Pump Unit

- Triplex Plunger Pumps

- Sewer Jetting Pump

- PressureJet ES Series Sewer Jetting Pump Max Flow Rate 412 Lpm

- PressureJet EM Series Sewer Jetting Pump Max Flow Rate 267 Lpm

- VA Series Sewer Jetting Pump Max Flow Rate 170 Lpm

- EA Series Sewer Jetting Pump Max Flow Rate 100 Lpm

- HW Series - Sewer Jetting Pump

- EA Series Sewer Jetting Pump Max Flow Rate 155 LPM

- Pressure Washer

- Jet Cleaners

- Water Blasting Machine

- High Pressure Water Jet Cleaner

- HIGH PRESSURE RECIPROCATING PUMPS

- Hydro Jetting Machine

- Extra Links

- Contact Us

Cold Water High Pressure Jet Cleaner

Price 110000.00 INR/ Unit

MOQ : 1 Unit

Cold Water High Pressure Jet Cleaner Specification

- Features

- Durable, Efficient

- Power Source

- Electric

- Usage

- General Cleaning , External Cleaning etc.

- Material

- Metal

- Type

- High Pressure Cleaner

- Size

- 55*37*37

- Condition

- New

- Height

- 37 Inch (in)

- Weight

- 190 Kilograms (kg)

- Color

- Yellow

- Length

- 55 Inch (in)

- Width

- 37 Inch (in)

Cold Water High Pressure Jet Cleaner Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Nhava Sheva ( Mumbai ) , Pipavav , Kandla

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- 100 Units Per Week

- Delivery Time

- 10 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box Packing Type

- Main Export Market(s)

- Western Europe, Australia, North America, South America, Eastern Europe, Central America, Middle East, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Cold Water High Pressure Jet Cleaner

We are committed to get excellence in the field of industrial cleaning by providing a premium quality range ofAAAA Cold Water High Pressure Jet Cleaner. Our offered cleaner is made at our latest machining facility by using quality assured materials and latest technology under the observations of veteran experts. Best known for its less maintenance, easy operation and low power consumption, ourAAAA Cold Water High Pressure Jet CleanerAAAA is ideal choice for outdoor areas cleaning. We can also custom made these cleaners as per the needs of the clients.

Product Details:

|

Minimum Order Quantity |

1 Unit |

|

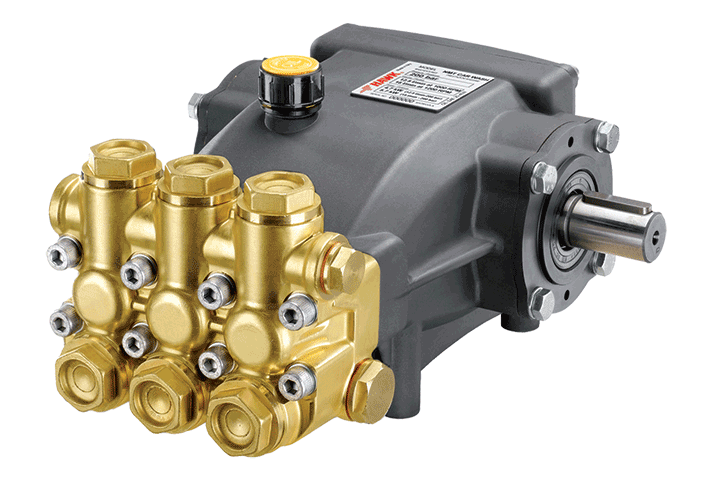

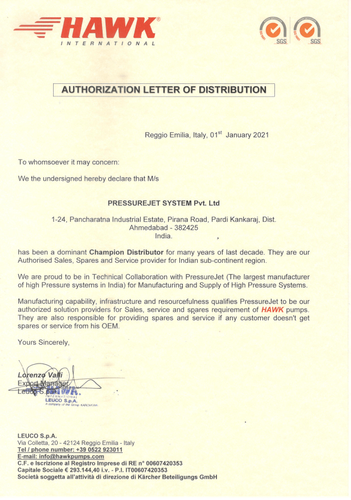

Bare Pump Brand |

Hawk |

|

Warranty |

1 year |

|

Rpm |

For 50 Hz - 1450 RPM |

|

Industry Type |

Manufacturing Industry |

|

Mounting Option |

Trolly Mounted, Skid Mounted |

|

Product Name Tags |

High Pressure Cleaner, Electric Motor Driven High Pressure Cleaner, High Pressurejet Cleaning Pump |

|

Product Tags |

Diesel Engine Driven High Pressurejet Cleaner, Water jet Cleaner |

|

Condition |

New |

|

System Brand |

PressureJet |

|

Motor HP |

10 HP |

|

Hz |

Available in 50 Hz and 60 Hz |

|

Driver Type |

Electric Motor Driven, Diesel engine Driven |

Robust High Pressure Performance

Experience superior cleaning power with a high flow rate of 15 LPM and strong pressure output. The advanced piston pump and electric motor ensure effective removal of dirt and debris, making this jet cleaner ideal for heavy-duty tasks in industrial and commercial environments.

Durable and Reliable Construction

Crafted from heavy-duty metal and fitted with fiber impregnated Buna-n seals, this jet cleaner promises enduring performance in rigorous settings. Its substantial structure withstands continuous use, guaranteeing operational stability and longer service life for users.

Versatile Applications Across Industries

Designed for a range of cleaning scenarios, this cleaner is suitable for fire control, general maintenance, and external surface cleaning. Its efficient design meets the dynamic needs of industries engaged in large-scale cleaning and facility management.

FAQ's of Cold Water High Pressure Jet Cleaner:

Q: How does the Cold Water High Pressure Jet Cleaner operate for general cleaning purposes?

A: The cleaner uses an electric-powered reciprocating piston pump that generates high-pressure water, effectively dislodging and removing debris from surfaces. Simply connect to a compatible water source via the BSPF inlet, power the unit, and direct the pressurized jet for efficient cleaning.Q: What types of industries and applications can benefit from this jet cleaner?

A: This machine is suitable for a wide range of fields, including fire services, facility maintenance, automotive, manufacturing plants, and external cleaning contractors. Its robust construction and high flow rate are particularly valuable for heavy-duty and frequent cleaning tasks.Q: When is it recommended to use a high-pressure jet cleaner like this instead of standard cleaning methods?

A: Use this high-pressure jet cleaner when conventional hand-cleaning or low-pressure systems are insufficient, such as when tackling persistent grime, large surface areas, or high-volume cleaning jobs. Its power and efficiency deliver significant time and labor savings.Q: Where can this high-pressure jet cleaner be installed or operated safely?

A: The jet cleaner is designed for use in industrial environments, outdoors, and in facilities equipped with proper electricity and water supply. Ensure stable ground, clear workspace, and adherence to safety protocols for optimal and safe operation.Q: What is the process for maintaining the durability and longevity of the jet cleaner?

A: Regularly inspect the Buna-n seals, check for leaks, and ensure all connections are secure. Clean and replace filters periodically, and follow the manufacturer's maintenance recommendations to preserve peak performance and durability.Q: What benefits does the durable fiber impregnated Buna-n seal provide?

A: The Buna-n seal offers enhanced resistance to wear, pressure, and chemicals, extending the service life and minimizing maintenance requirements. This ensures consistent, reliable operation in demanding cleaning scenarios.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Water Jet Cleaner Category

Industrial Water Jetting Cleaner

Price 375000 INR

Minimum Order Quantity : 1 Unit

Seals Type : Special Teflon base high pressure seal

Material : Metal

Cleaning Type : High Pressure Cleaner

Usage : Other

PressureJet Industrial Water Jet Cleaning Machine

Price 150000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Seals Type : Durable Fiber Impregnated Bunan Seal

Material : Metal

Cleaning Type : High Pressure Cleaner

Usage : Hydro Jetting , General Cleaning etc.

Industrial Pressure Cleaner

Price 79000 INR / Unit

Minimum Order Quantity : 1 Unit

Seals Type : Durable Fiber Impregnated Bunan Seal

Material : Metal

Cleaning Type : High Pressure Cleaner

Usage : Other

PressureJet High Pressure Water Jet Cleaning Machine

Price 150000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Seals Type : Durable Fiber Impregnated Bunan Seal

Material : Metal

Cleaning Type : High Pressure Cleaner

Usage : Other

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free