- Home Page

- Company Profile

-

Our Products

- Hydro Jetting Machine

- 1000 Bar 10000 PSI Electric Pressure Washer

- PressureJet Hydro Jetting Pump

- Hydro Jetting System

- Hydro Jetting Machine PressureJet

- PressureJet Hydro Jet Cleaning Machine

- Hydro Jetting Machines

- 20000 PSI Hydro Jetting Machine

- High Pressure Hydro Jetting Equipment

- High Pressure Hydro Jetting Machine

- Hydro Jetting Machine

- Hydro Jetting Equipment

- Hydro Blasting Machine

- 20K Hydroblaster Semi-Automatic Hydroblaster 20 K

- Pressure Jet Hydro Blasting Equipment

- 10000 PSI Hydro Blaster Semi-Automatic Hydro Blaster 10000 PSI

- 10K Water Blaster Semi-Automatic Water Blaster 10 K

- High Pressure Hydro Blasting System

- Pressure Jet Semi-Automatic Hydro Blasting Equipment

- Pressure Jet 3 Phase High Pressure Water Blaster

- 3 Phase Pumps 20000 PSI Pressure Washer

- Water Jet Cleaner

- Hydro Test Pump

- PressureJet Brass, S.s High Pressure Hydrotest Pump (Hydrostatic Test ) , Max Flow Rate: 197

- Stainless Steel Hydro Test Pump

- High Pressure Hydro Test Pump

- Motorized Hydro Test Pump

- Triplex Plunger Hydro Test Pump

- High Pressure Hydrostatic Test Pump

- Hydrostatic Pressure Testing Pump

- Diesel Driven Hydro Test Pump

- High Pressure Hydro Test Pump Unit

- Triplex Plunger Pumps

- Sewer Jetting Pump

- PressureJet ES Series Sewer Jetting Pump Max Flow Rate 412 Lpm

- PressureJet EM Series Sewer Jetting Pump Max Flow Rate 267 Lpm

- VA Series Sewer Jetting Pump Max Flow Rate 170 Lpm

- EA Series Sewer Jetting Pump Max Flow Rate 100 Lpm

- HW Series - Sewer Jetting Pump

- EA Series Sewer Jetting Pump Max Flow Rate 155 LPM

- Pressure Washer

- Jet Cleaners

- Water Blasting Machine

- High Pressure Water Jet Cleaner

- HIGH PRESSURE RECIPROCATING PUMPS

- Hydro Jetting Machine

- Extra Links

- Contact Us

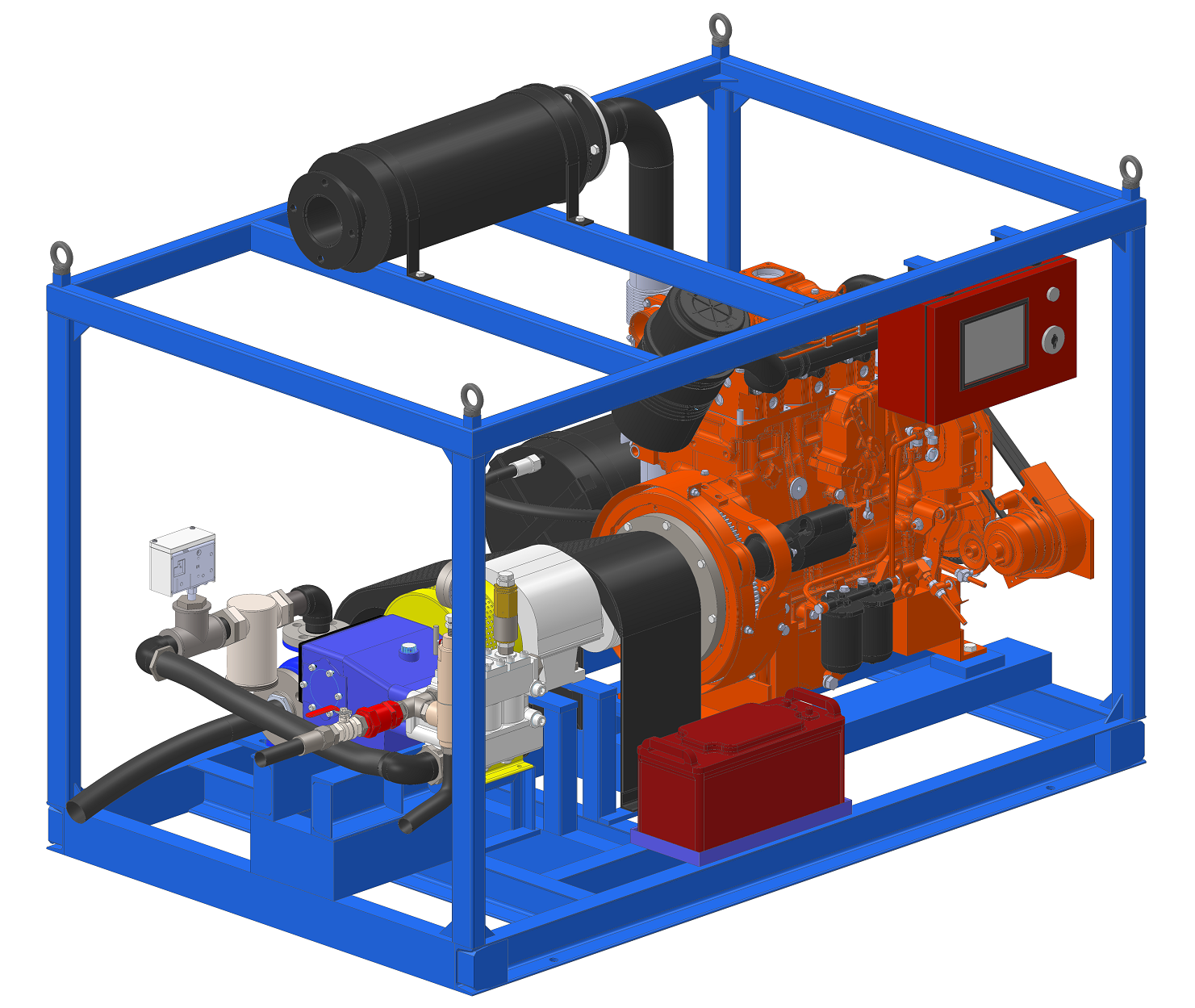

High Pressure Hydro Blasting System

Price 150000 INR/ Unit

MOQ : 1 Unit

High Pressure Hydro Blasting System Specification

- Usage

- Hydro Blasting

- Motor Type

- IE2 Non-FLP Foot Mounted

- Size

- 1286*641*451

- Height

- 215 Millimeter (mm)

- Product Type

- Hydro Blasting Machine

- Weight

- Approx weight of bare pump: 85 Kilograms (kg)

- Color

- Blue

- Length

- 510 Millimeter (mm)

- Width

- 464 Millimeter (mm)

- Voltage

- 220-440 Volt (v)

High Pressure Hydro Blasting System Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Nhava Sheva ( Mumbai ) , Pipavav , Kandla

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- 10 Units Per Day

- Delivery Time

- 2 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box Type Packing

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Africa, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About High Pressure Hydro Blasting System

Product Details:

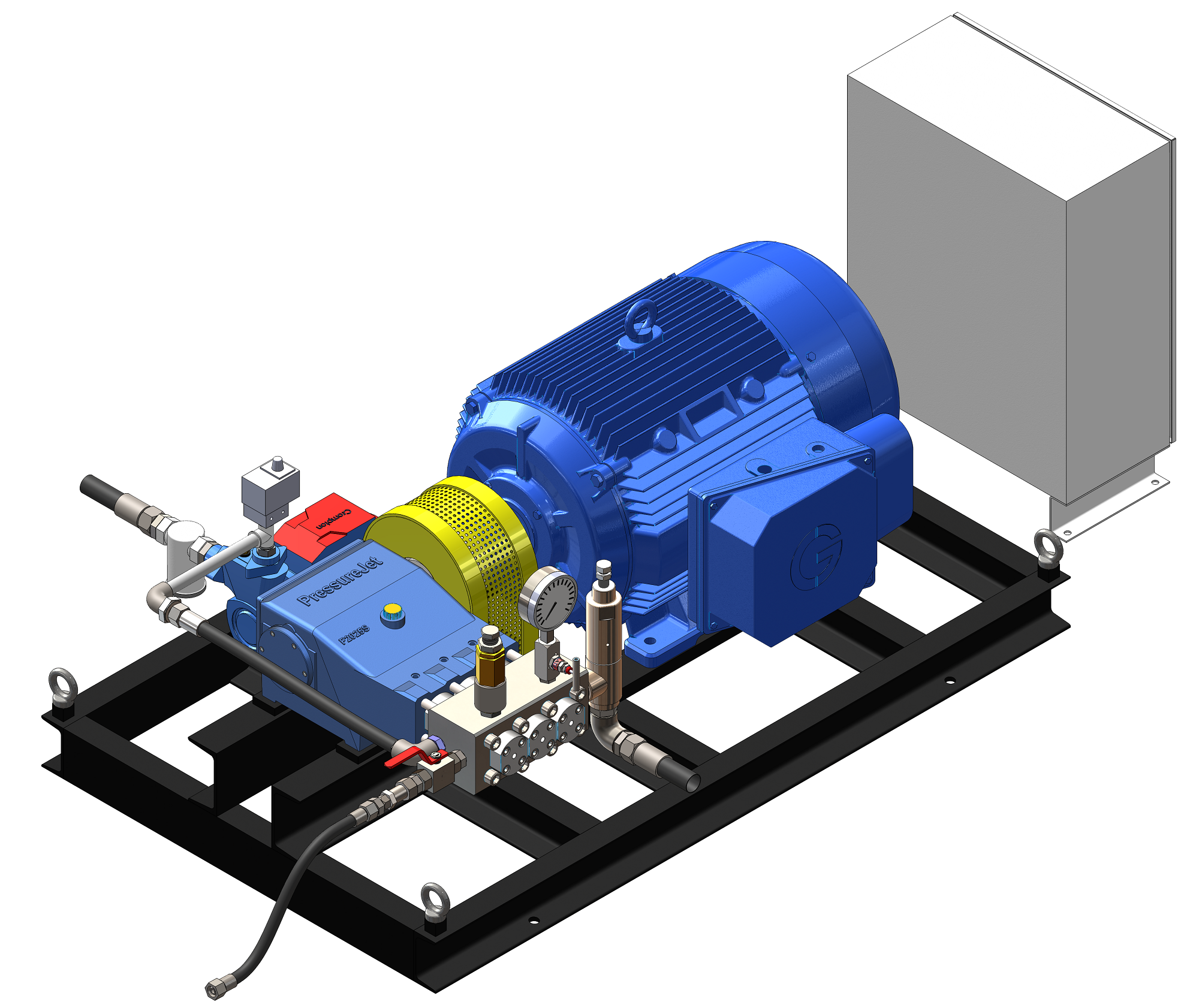

|

Color |

Blue |

|

Material |

Stainless steel |

|

Pressure Range in Bar |

250 bar to 1000 bar |

|

Portable |

Yes |

|

Phase |

3 Phase Pumps |

|

Media |

Pure Water |

|

Flow Rate Range in LPM |

13 LPM to 55 LPM |

|

Mounting Type |

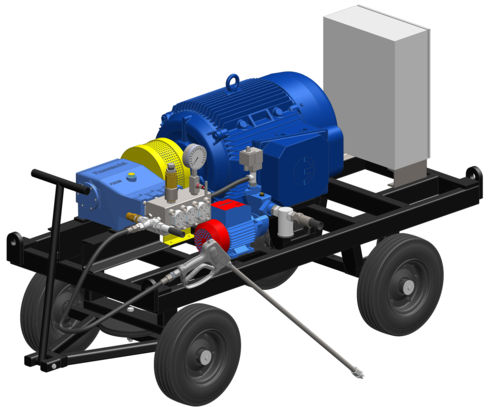

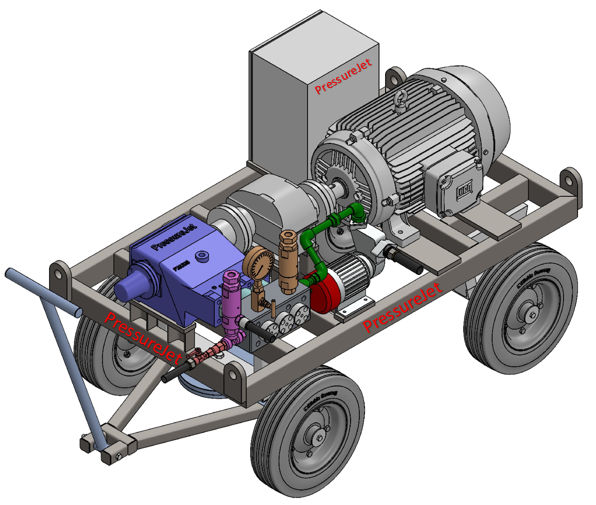

Skid Mounted, Trolley Mounted |

|

Body Material |

Cast Iron |

|

Brand |

PressureJet |

|

Automatic Grade |

Semi-Automatic |

|

Condition |

New |

|

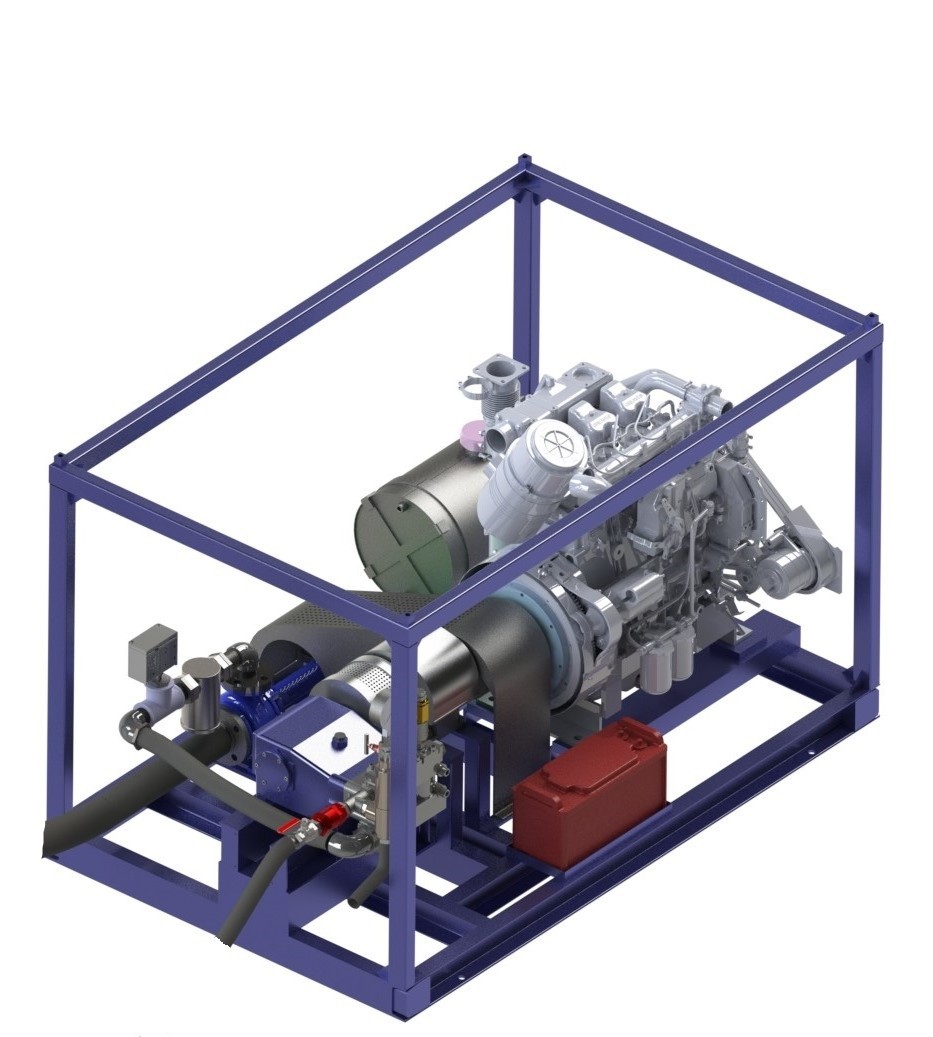

Driven Type |

Electric Motor Driven, Diesel Engine Driven |

|

Certification |

ISO 9001 : 2015 |

|

Automation Grade |

Semi-Automatic |

Efficient Surface Preparation

This hydro blasting system provides a powerful, precise solution for removing paint, rust, and contaminants from surfaces. Its high-pressure water jet technology ensures minimal surface damage while maximizing cleaning efficiency, making it ideal for industrial and commercial maintenance tasks.

Durable Stainless Steel Construction

The system's liquid end is manufactured from premium stainless steel, ensuring superior resistance to corrosion and longevity. This robust construction guarantees consistent performance and reduced maintenance requirements, even with demanding usage.

Power and Portability Combined

Despite its solid build and high weight of 85 kg, the hydro blasting system remains relatively compact, measuring 510 mm in length, 464 mm in width, and 215 mm in height. Its portability allows for easy deployment across various job sites, supported by a reliable electric power mode.

FAQ's of High Pressure Hydro Blasting System:

Q: How does the High Pressure Hydro Blasting System operate?

A: This system works by directing a high-pressure stream of water, delivered via a pump with an SS liquid end, onto surfaces. This process effectively strips away paint, rust, and other contaminants without damaging the underlying material.Q: What are the main applications of this hydro blasting system?

A: The equipment is primarily used for surface preparation, paint and coating removal, and cleaning of industrial equipment or structures. Its versatility makes it suitable for manufacturing plants, maintenance facilities, and refurbishing operations.Q: When should I use hydro blasting over other cleaning techniques?

A: Hydro blasting is preferable when you need thorough cleaning without the use of chemicals or abrasive materials. It is especially effective for stubborn coatings, minimizing environmental impact and reducing the risk of substrate damage.Q: Where can this hydro blasting system be deployed?

A: The system can be used indoors or outdoors in a variety of industrial settings, including manufacturing sites, shipyards, factories, and construction projects across India.Q: What is the process for operating and maintaining the system?

A: Connect the system to the appropriate power supply (415V), ensure adequate water inflow, and follow manufacturer safety protocols. Regular cleaning, inspection, and periodic maintenance of the SS liquid end are essential for optimal performance.Q: What are the benefits of choosing a stainless steel (SS) liquid end?

A: A stainless steel liquid end offers excellent resistance to corrosion, extending equipment life and ensuring high-pressure capability remains intact despite frequent use with various liquids.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Hydro Blasting Machine Category

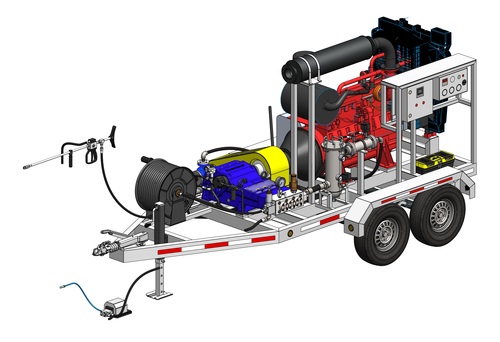

Pressure Jet Hydro Blasting Equipment

Price 750000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Blue, yellow , Brown

Voltage : 220440 Volt (v)

Usage : Hydro Blasting

Length : 948 Millimeter (mm)

Pressure Jet 3 Phase High Pressure Water Blaster

Price 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Blue, yellow , Brown

Voltage : 220440 Volt (v)

Usage : Hydro Blasting , Hydro Jetting , Hydro Test

Length : 1286 Millimeter (mm)

3 Phase Pumps 20000 PSI Pressure Washer

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Blue

Voltage : 220440 Volt (v)

Usage : Hydro Blasting

Length : 1286 Millimeter (mm)

10K Water Blaster Semi-Automatic Water Blaster 10 K

Price 750000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Blue

Voltage : 220440 Volt (v)

Usage : Hydro Blasting , Hydro Jetting , Hydro Test

Length : 510 Millimeter (mm)

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS