- Home Page

- Company Profile

-

Our Products

- Hydro Jetting Machine

- 1000 Bar 10000 PSI Electric Pressure Washer

- PressureJet Hydro Jetting Pump

- Hydro Jetting System

- Hydro Jetting Machine PressureJet

- PressureJet Hydro Jet Cleaning Machine

- Hydro Jetting Machines

- 20000 PSI Hydro Jetting Machine

- High Pressure Hydro Jetting Equipment

- High Pressure Hydro Jetting Machine

- Hydro Jetting Machine

- Hydro Jetting Equipment

- Hydro Blasting Machine

- 20K Hydroblaster Semi-Automatic Hydroblaster 20 K

- Pressure Jet Hydro Blasting Equipment

- 10000 PSI Hydro Blaster Semi-Automatic Hydro Blaster 10000 PSI

- 10K Water Blaster Semi-Automatic Water Blaster 10 K

- High Pressure Hydro Blasting System

- Pressure Jet Semi-Automatic Hydro Blasting Equipment

- Pressure Jet 3 Phase High Pressure Water Blaster

- 3 Phase Pumps 20000 PSI Pressure Washer

- Water Jet Cleaner

- Hydro Test Pump

- PressureJet Brass, S.s High Pressure Hydrotest Pump (Hydrostatic Test ) , Max Flow Rate: 197

- Stainless Steel Hydro Test Pump

- High Pressure Hydro Test Pump

- Motorized Hydro Test Pump

- Triplex Plunger Hydro Test Pump

- High Pressure Hydrostatic Test Pump

- Hydrostatic Pressure Testing Pump

- Diesel Driven Hydro Test Pump

- High Pressure Hydro Test Pump Unit

- Triplex Plunger Pumps

- Sewer Jetting Pump

- PressureJet ES Series Sewer Jetting Pump Max Flow Rate 412 Lpm

- PressureJet EM Series Sewer Jetting Pump Max Flow Rate 267 Lpm

- VA Series Sewer Jetting Pump Max Flow Rate 170 Lpm

- EA Series Sewer Jetting Pump Max Flow Rate 100 Lpm

- HW Series - Sewer Jetting Pump

- EA Series Sewer Jetting Pump Max Flow Rate 155 LPM

- Pressure Washer

- Jet Cleaners

- Water Blasting Machine

- High Pressure Water Jet Cleaner

- HIGH PRESSURE RECIPROCATING PUMPS

- Hydro Jetting Machine

- Extra Links

- Contact Us

High Pressure Jet Cleaner

Price 175000 INR/ Unit

MOQ : 1 Unit

High Pressure Jet Cleaner Specification

- Material

- Metal

- Usage

- Hydro Jetting, High Pressure Jet Cleaners

- Type

- High Pressure Cleaner

- Size

- 54*36*36

- Condition

- New

- Height

- 36 Inch (in)

- Use

- Container / Bottle Cleaning, Descaling / Stripping

- Weight

- 250 Kilograms (kg)

- Cleaning Process

- Cold Water Cleaning

- Color

- Yellow

- Cleaning Type

- High Pressure Cleaner

- Width

- 36 Inch (in)

- Length

- 54 Inch (in)

- Voltage

- 415 Volt (v)

High Pressure Jet Cleaner Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Nhava Sheva ( Mumbai ) , Pipavav , Kandla

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- 100 Units Per Week

- Delivery Time

- 10 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box Type Packaging

- Main Export Market(s)

- Australia, North America, Eastern Europe, Western Europe, Central America, Middle East, South America, Asia, Africa

- Main Domestic Market

- All India

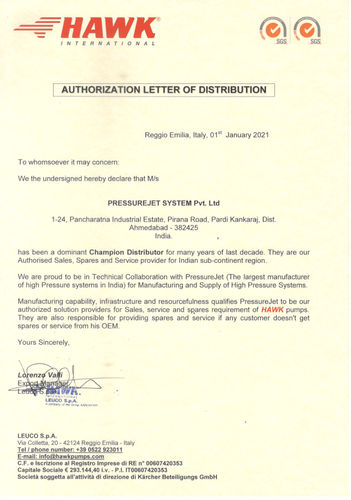

- Certifications

- ISO 9001 : 2015

About High Pressure Jet Cleaner

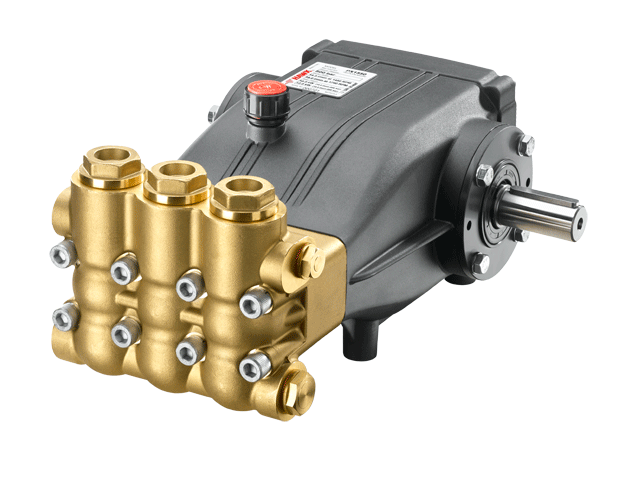

The offered High Pressure Jet Cleaner is made available by us for use in the various commercial and industrial applications. A pressure washing surface cleaner is a tool consisting of two to four high-pressure jets on a rotating bar that swivels when water is flowing. This action creates a uniformed cleaning pattern that can clean flat surfaces at a rapid rate. It is a low foaming, multipurpose, medium duty, alkaline cleaner that emulsifies fats and oils, and cleans a wide variety of food soils. The offered High Pressure Jet Cleaner is very effective and safe for use and easy to operate.Product Details:

|

Bare Pump Brand |

Hawk |

|

Remote Control |

No |

|

Rpm |

For 50 Hz - 1450 RPM |

|

Auto Stop |

Yes |

|

Phase |

3 Phase |

|

Flow Rate |

17 LPM |

|

Power Supply |

Available in 50 Hz and 60 Hz |

|

Condition |

New |

|

Automation Grade |

Semi-Automatic |

|

Industry Type |

Manufacturing Industry |

|

Material |

Liquid End Material - Brass |

|

Portable |

Yes |

|

Driven Type Available |

Electric Motor Driven, Diesel engine Driven |

|

Mounting Option |

Trolly Mounted, Skid Mounted |

|

Product Name Tags |

High Pressure Cleaner, Electric Motor Driven High Pressure Cleaner, High Pressurejet Cleaning Pump |

|

Product Tags |

Diesel Engine Driven High Pressurejet Cleaner, Water jet Cleaner |

|

System Brand |

Pressure Jet |

|

Motor HP |

15 HP |

Durable Design for Industrial Use

Crafted from high-grade metal and finished in a visible yellow, the High Pressure Jet Cleaner delivers durability and longevity. Its solid structure ensures reliable operation in intensive cleaning environments, making it suitable for factories, warehouses, and manufacturing plants.

Versatile Cleaning Applications

Equipped for a wide range of functions, this cleaner is adept at hydro jetting, descaling, stripping, and cleaning containers or bottles. The powerful system utilizes cold water at high pressure, facilitating thorough cleaning without damaging materials or requiring additional heat.

Efficient Operation & User-Friendly

This high-pressure cleaner operates at 415 volts, providing consistent and powerful performance. The thoughtfully designed controls and accessible size make it easy to maneuver and operate, allowing users to maximize productivity and achieve first-rate results with minimal effort.

FAQ's of High Pressure Jet Cleaner:

Q: How does the High Pressure Jet Cleaner function for industrial cleaning?

A: This cleaner uses cold water propelled at high pressure to break down and remove tough residues, scales, and deposits from a variety of surfaces, such as industrial containers or bottles. Its robust metal construction allows for reliable operation even during demanding applications.Q: What materials can be safely cleaned using this jet cleaner?

A: The high pressure jet cleaner is suitable for cleaning metal, glass, and plastic containers or bottles, as well as surfaces requiring descaling and stripping, ensuring a thorough yet non-destructive cleaning process.Q: When should I use this cleaner for descaling or hydro jetting?

A: It is best employed during routine maintenance or whenever you notice buildup or scaling on equipment surfaces. Prompt usage helps prevent operational issues and maintains optimal equipment performance.Q: Where can this high pressure cleaner be deployed effectively?

A: This machine is ideal for use in industrial plants, factories, warehouses, and areas where container, bottle cleaning, or descaling is required, particularly where cold water cleaning is necessary for sensitive materials.Q: What is the cleaning process involved with this equipment?

A: The cleaner operates on a cold water high pressure cleaning process. Water is forced through a narrow nozzle at high velocity, striking surfaces with enough force to dislodge stubborn dirt, scale, and residues without heat.Q: What are the usage benefits of the High Pressure Jet Cleaner?

A: The primary benefits include effective removal of contaminants, minimal surface damage, reduced chemical usage, and faster cleaning cycles. This enhances operational efficiency and extends the lifespan of cleaned equipment.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Jet Cleaners Category

65 Bar TO 500 Bar Heavy Duty Jet Cleaner

Price 150000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Cleaning Process : Cold Water Cleaning

Usage : Cleaning After Pickling, Floor Cleaning, Surface Clearing, Dust Removal, Paint Removal, Boiler Surface Cleaning, APH Basket Cleaning, AHU Filter Cleaning, Cement Concrete Mixture Cleaning, Scaffolding Cleaning, Rig Washing, Live Wire Insulator Cleaning, Earth Moving Equipment Cleaning and Many More Industrial Applications.

Height : 510 Millimeter (mm)

Cold Water High Jet Cleaner

Price 150000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Cleaning Process : Cold Water Cleaning

Usage : General Cleaning , Boiler Cleaning , AHU Cleaning , External Cleaning etc.

Height : 30 Inch (in)

3 Phase High Pressure Cleaner

Price 79000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Cleaning Process : Cold Water Cleaning

Usage : General Cleaning , Boiler Cleaning , Evaporator Cleaning , External Cleaning etc.

Height : 24 Inch (in)

High Pressure Water Jet Cleaning Machine Manufacturers

Price 150000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Cleaning Process : Cold Water Cleaning

Usage : High Pressure Cleaning , Jet Cleaning, General Cleaning etc.

Height : 42 Inch (in)

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS