- Home Page

- Company Profile

-

Our Products

- Hydro Jetting Machine

- 1000 Bar 10000 PSI Electric Pressure Washer

- PressureJet Hydro Jetting Pump

- Hydro Jetting System

- Hydro Jetting Machine PressureJet

- PressureJet Hydro Jet Cleaning Machine

- Hydro Jetting Machines

- 20000 PSI Hydro Jetting Machine

- High Pressure Hydro Jetting Equipment

- High Pressure Hydro Jetting Machine

- Hydro Jetting Machine

- Hydro Jetting Equipment

- Hydro Blasting Machine

- 20K Hydroblaster Semi-Automatic Hydroblaster 20 K

- Pressure Jet Hydro Blasting Equipment

- 10000 PSI Hydro Blaster Semi-Automatic Hydro Blaster 10000 PSI

- 10K Water Blaster Semi-Automatic Water Blaster 10 K

- High Pressure Hydro Blasting System

- Pressure Jet Semi-Automatic Hydro Blasting Equipment

- Pressure Jet 3 Phase High Pressure Water Blaster

- 3 Phase Pumps 20000 PSI Pressure Washer

- Water Jet Cleaner

- Hydro Test Pump

- PressureJet Brass, S.s High Pressure Hydrotest Pump (Hydrostatic Test ) , Max Flow Rate: 197

- Stainless Steel Hydro Test Pump

- High Pressure Hydro Test Pump

- Motorized Hydro Test Pump

- Triplex Plunger Hydro Test Pump

- High Pressure Hydrostatic Test Pump

- Hydrostatic Pressure Testing Pump

- Diesel Driven Hydro Test Pump

- High Pressure Hydro Test Pump Unit

- Triplex Plunger Pumps

- Sewer Jetting Pump

- PressureJet ES Series Sewer Jetting Pump Max Flow Rate 412 Lpm

- PressureJet EM Series Sewer Jetting Pump Max Flow Rate 267 Lpm

- VA Series Sewer Jetting Pump Max Flow Rate 170 Lpm

- EA Series Sewer Jetting Pump Max Flow Rate 100 Lpm

- HW Series - Sewer Jetting Pump

- EA Series Sewer Jetting Pump Max Flow Rate 155 LPM

- Pressure Washer

- Jet Cleaners

- Water Blasting Machine

- High Pressure Water Jet Cleaner

- HIGH PRESSURE RECIPROCATING PUMPS

- Hydro Jetting Machine

- Extra Links

- Contact Us

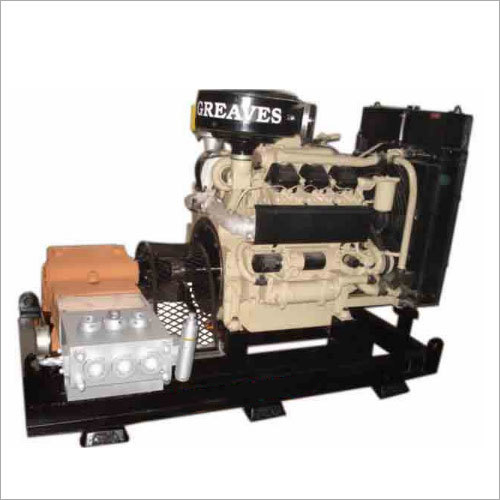

Hydro Jetting Equipment

MOQ : 1 Unit

Hydro Jetting Equipment Specification

- Usage

- General Cleaning , Boiler Tube Cleaning , Evaporator Tube Cleaning , External Cleaning etc.

- Material

- Metal

- Type

- High Pressure Cleaner

- Condition

- New

- Fuel Type

- Diesel

- Use

- Container / Bottle Cleaning

- Cleaning Process

- Cold Water Cleaning

- Color

- Blue

- Cleaning Type

- High Pressure Cleaner

- Voltage

- 415 Volt (v)

Hydro Jetting Equipment Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Kandla , Nhava Sheva Mumbai

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- 10 Units Per Day

- Delivery Time

- 2 Week

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box Type Packaging

- Main Export Market(s)

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Central America, Africa, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Hydro Jetting Equipment

PRESSUREJET manufactures High Pressure Hydro Jetting Machine for the pressures ranging from140 bar (2000 PSI) to 1400 bar (20,000 PSI).This pressure range meet the tube cleaning requirements of most industrial applications.

PressureJet offers tube & pipe cleaning and High Pressure Water Jetting Machines forHeat Exchanger, Condenser, Evaporator, Calendria, Boileretc. in various industries liketextile, pharmaceutical, steel, chemical, refineries and many more.For over a decade now,

PressureJet has been theFIRST CHOICE of Hydro Jetting Contractorsas well as leading companies due to Product Quality, Infrastructure, Assembly & Testing Facilities, Engineering Practices, Inventory Management, Customer Friendly Approach and many more.

Accessories -

PressureJet also offers various accessories with Hydro Jetting Machine.

- Tube and Pipe Cleaning Rotating Nozzle

- Tube and Pipe Cleaning Conventional Nozzle

- Rigid Lance which used in Hydro Jetting Equipment.

- Foot Operated Valve (the most important part of the Hydro Jetting Systems).

- High Pressure Flexible Lance

- Hydro Jetting Pressure Regulating Valve

- Safety Valve Etc...

Additional Information:

- Item Code: KD24

- Pay Mode Terms: T/T (Bank Transfer)

- Port of Dispatch: Ahmedabad

- Production Capacity: 50 pumps per month

- Delivery Time: Approx. 3 to 4 weeks (For exact time contact sales dept. sales@pressurejet.com)

- Packaging Details: Box Type Packaging TD P { margin-bottom: 0cm; }P { margin-bottom: 0.21cm; }

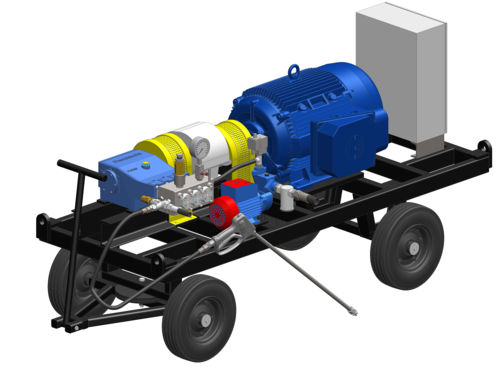

Product Details:

|

Product Details: |

|

|

Minimum Order Quantity |

1 Unit |

|

Warranty |

1 Year |

|

Phase |

3 Phase Pump |

|

Brand |

PressureJet |

|

Material |

Liquid End Material: - SS |

|

Driver type |

Electric motor driven, Diesel engine driven |

|

Mounting option |

Trolley mounted, Skid mounted |

|

Suitable for |

Medium hard scale and long length tubes and pipes cleaning / Hydro Jetting. |

|

Product tags |

Hydro Jetting Machine, 3 Phase High Pressure Hydro Jetting System, High Pressure Pumps |

|

Product name tags |

Hydro Jetting Systems, High PressureJet Pumps |

|

Pressure |

655 Bar |

|

Flow rate |

62 LPM |

|

Motor HP |

100 HP |

|

Hz |

Available in 50 Hz and 60 Hz |

|

RPM |

For 50 Hz - 1450 RPM and 60 Hz - 1740 RPM |

|

No Of Wheels |

4 Wheels |

Efficient Cleaning Solutions for Diverse Industries

The Hydro Jetting Equipment offers exceptional results for cleaning complex surfaces and machinery such as boiler and evaporator tubes, as well as containers and bottles. Its high-pressure, cold water process ensures deep cleaning without damaging equipment, making it a reliable choice across power plants, chemical industries, and manufacturing units. The robust metal construction ensures longevity even in demanding environments.

Powered by Diesel for Maximum Mobility

No need to rely on external electricity sources: this equipment is diesel-powered, allowing for versatile use in remote or mobile locations. The integration with a sturdy 415 Volt power system ensures consistent performance and safety during operation, making it a preferred solution for service providers and industrial teams.

FAQ's of Hydro Jetting Equipment:

Q: How does the Hydro Jetting Equipment operate for cleaning applications?

A: The equipment uses cold water blasted at high pressure, powered by diesel, to effectively dislodge and remove deposits from surfaces like boiler tubes, containers, and bottles. Connect to a 415 Volt power supply, set the desired pressure, and direct the jet onto the area that requires cleaning.Q: What specific benefits does this equipment offer for boiler and evaporator tube cleaning?

A: Its high pressure capability allows thorough removal of scaling, residue, and built-up deposits from tubes and evaporators, enhancing equipment efficiency and lifespan. The cold water process minimizes risk of thermal shock and material damage, making it ideal for industrial cleaning requirements.Q: Where can the Hydro Jetting Equipment be used?

A: It can be deployed in industries such as power generation, chemical processing, manufacturing, and more. Typical usage includes general cleaning, tube cleaning, container and bottle cleaning, and external surface treatment in facilities across India.Q: When should hydro jetting be performed in industrial cleaning processes?

A: Hydro jetting is recommended during regular maintenance, especially when equipment shows signs of decreased efficiency due to contamination or scaling. It reduces downtime by ensuring thorough cleaning in shorter time frames compared to manual methods.Q: What is the cleaning process for container and bottle cleaning using this equipment?

A: Operators position the high-pressure jet to target the container or bottle, ensuring that all internal and external surfaces are reached. Adjusting pressure settings allows customized cleaning intensity for different materials and residue types, delivering optimal results.Q: How does using high pressure with cold water differ from other cleaning methods?

A: Cold water jetting with high pressure is less likely to damage surfaces and is suitable for heat-sensitive components. Unlike chemical cleaners, it leaves no residues or by-products, making it an environmentally-friendly and non-corrosive option.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Hydro Jetting Machine Category

Hydro Jetting Machine PressureJet

Price 560000 INR / Unit

Minimum Order Quantity : 1 Unit

Fuel Type : Electric

Length : 686 Millimeter (mm)

Condition : New

Use : Other

Hydro Jetting Machine

Price 1000000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Fuel Type : Diesel

Length : 220 Centimeter (cm)

Condition : New

Use : Other

Hydro Jetting Machines

Price 250000 INR / Unit

Minimum Order Quantity : 1 Unit

Fuel Type : Electric

Length : 60 Inch (in)

Condition : New

Use : Other

High Pressure Hydro Jetting Equipment

Price 1540000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Fuel Type : Electric

Length : 1286 Millimeter (mm)

Condition : New

Use : Other

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS