- Home Page

- Company Profile

-

Our Products

- Hydro Jetting Machine

- 1000 Bar 10000 PSI Electric Pressure Washer

- PressureJet Hydro Jetting Pump

- Hydro Jetting System

- Hydro Jetting Machine PressureJet

- PressureJet Hydro Jet Cleaning Machine

- Hydro Jetting Machines

- 20000 PSI Hydro Jetting Machine

- High Pressure Hydro Jetting Equipment

- High Pressure Hydro Jetting Machine

- Hydro Jetting Machine

- Hydro Jetting Equipment

- Hydro Blasting Machine

- 20K Hydroblaster Semi-Automatic Hydroblaster 20 K

- Pressure Jet Hydro Blasting Equipment

- 10000 PSI Hydro Blaster Semi-Automatic Hydro Blaster 10000 PSI

- 10K Water Blaster Semi-Automatic Water Blaster 10 K

- High Pressure Hydro Blasting System

- Pressure Jet Semi-Automatic Hydro Blasting Equipment

- Pressure Jet 3 Phase High Pressure Water Blaster

- 3 Phase Pumps 20000 PSI Pressure Washer

- Water Jet Cleaner

- Hydro Test Pump

- PressureJet Brass, S.s High Pressure Hydrotest Pump (Hydrostatic Test ) , Max Flow Rate: 197

- Stainless Steel Hydro Test Pump

- High Pressure Hydro Test Pump

- Motorized Hydro Test Pump

- Triplex Plunger Hydro Test Pump

- High Pressure Hydrostatic Test Pump

- Hydrostatic Pressure Testing Pump

- Diesel Driven Hydro Test Pump

- High Pressure Hydro Test Pump Unit

- Triplex Plunger Pumps

- Sewer Jetting Pump

- PressureJet ES Series Sewer Jetting Pump Max Flow Rate 412 Lpm

- PressureJet EM Series Sewer Jetting Pump Max Flow Rate 267 Lpm

- VA Series Sewer Jetting Pump Max Flow Rate 170 Lpm

- EA Series Sewer Jetting Pump Max Flow Rate 100 Lpm

- HW Series - Sewer Jetting Pump

- EA Series Sewer Jetting Pump Max Flow Rate 155 LPM

- Pressure Washer

- Jet Cleaners

- Water Blasting Machine

- High Pressure Water Jet Cleaner

- HIGH PRESSURE RECIPROCATING PUMPS

- Hydro Jetting Machine

- Extra Links

- Contact Us

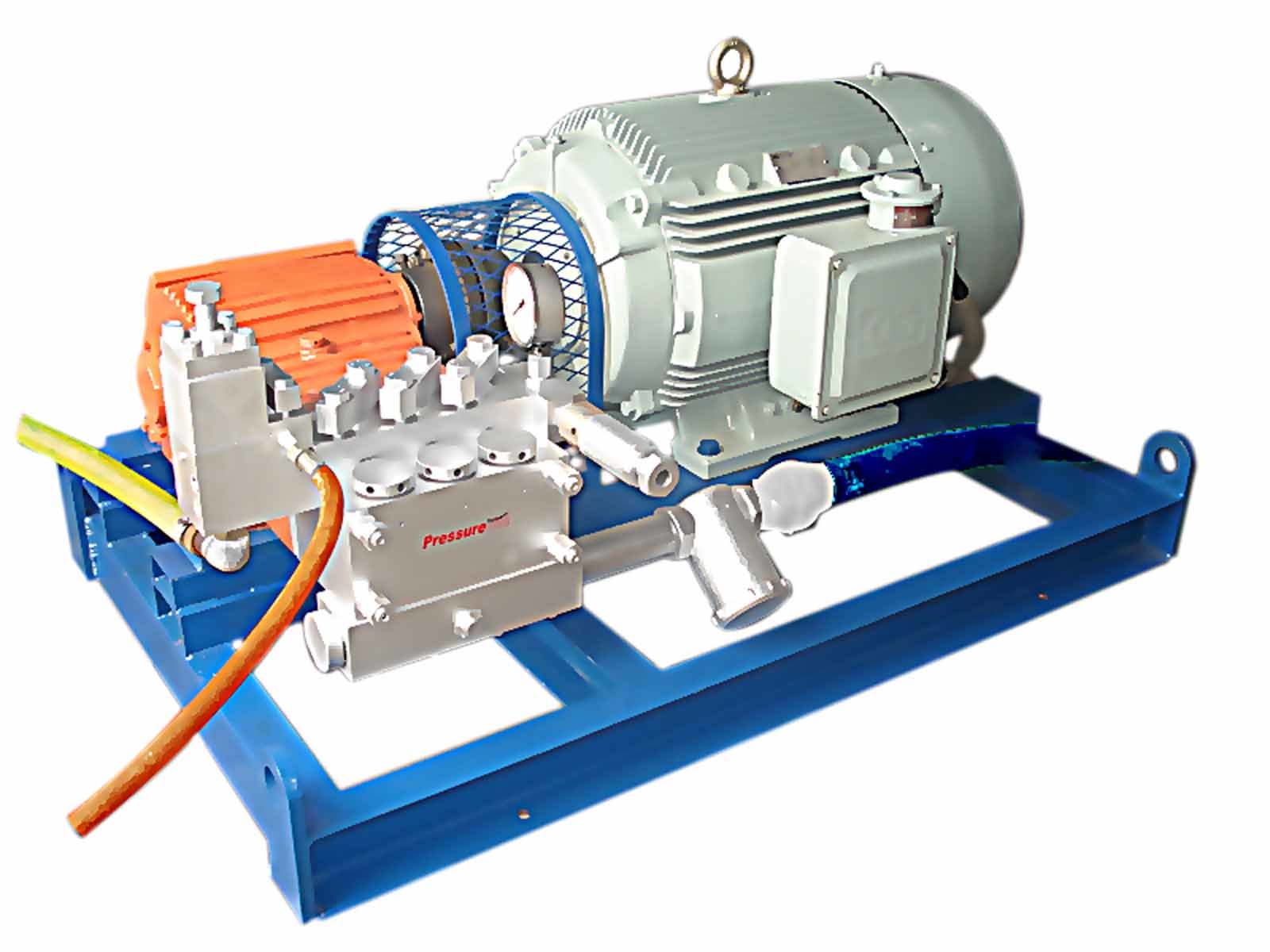

Pressure Jet Stainless Steel Hydro Blasting Machine

Price 200000 INR/ Unit

MOQ : 1 Unit

Pressure Jet Stainless Steel Hydro Blasting Machine Specification

- Usage

- Hydro Blasting , Hydro Jetting , Hydro Test

- Motor Type

- IE2 Non-FLP Foot Mounted

- Size

- 1286*641*451

- Product Type

- Hydro Blasting Machine

- Weight

- Approx weight of bare pump: 85 Kilograms (kg)

- Application

- Mining, Stone, Chemical Industry

- Color

- Blue

- Width

- 464 Millimeter (mm)

- Length

- 510 Millimeter (mm)

- Voltage

- 220-440 Volt (v)

Pressure Jet Stainless Steel Hydro Blasting Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Nhava Sheva ( Mumbai ) , Pipavav , Kandla

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- 10 Units Per Day

- Delivery Time

- 2 Week

- Packaging Details

- Wooden Box Type Packing

- Main Export Market(s)

- Western Europe, Eastern Europe, Middle East, Central America, Africa, South America, Australia, Asia, North America

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Pressure Jet Stainless Steel Hydro Blasting Machine

Pressure Jet Stainless Steel Hydro Blasting Machine is suited for various processes such as hydro demolition, investment casting cleaning, oxidation removal, chloride removal, asbestos removal, corrosion exclusion etc. This is also applicable for historic cobblestone restoration, pool refurbishing, marine surface prep, and paint removal from ships, water jet cutting, concrete surface preparation, tank cleaning, oil field cleaning, heat exchanger tube cleaning, surface preparation, vessel cleaning, deburring and others. Pressure Jet Stainless Steel Hydro Blasting Machine has a 3 phase pump, trolley & skid mounted structures etc. Pressurejet Systems Pvt. Ltd makes use of direct high pressure water streams so that the material can be cleaned and cut, according to the application needs. It is exclusively demanded for the surface preparation in shipping industry.

Product Details:

|

Driver type |

Electric motor driven, Diesel engine driven |

|

Brand |

Pressure Jet |

|

Water Flow (Lpm) |

45 LPM |

|

Motor Power (HP) |

75 HP |

|

Automation Grade |

Semi-Automatic |

|

Mounting Type |

Trolley mounted, Skid mounted |

|

Color |

Blue |

|

Material |

Liquid End Material: - SS |

|

warranty |

1 year |

|

RPM |

For 50 Hz - 1450 RPM and 60 Hz - 1740 RPM |

|

Product tags |

Hydro Blasting Machine, 3 Phase High Pressure Hydro Blasting Machine, High Pressure Pumps |

|

Product name tags |

Hydro Blasting Machine, High PressureJet Pumps |

|

Phase |

3 Phase Pump |

|

Max Pressure |

625 Bar |

|

Hz |

Available in 50 Hz and 60 Hz |

Efficient Cleaning and Industrial Testing

This hydro blasting machine stands out for its high performance in tough environments such as mining, stone yards, and chemical plants. Its stainless steel construction enhances longevity and ensures reliable operation even under harsh conditions. The equipment is versatile-capable of handling demanding hydro jetting and hydro testing applications with ease.

Comprehensive Market Availability Across India

The Pressure Jet Stainless Steel Hydro Blasting Machine is offered through a wide network in India. Whether you need to purchase, export, or acquire servicing and support, the product is accessible via distributors, manufacturers, service providers, suppliers, and traders. This ensures fast availability and expert assistance for all user needs.

FAQ's of Pressure Jet Stainless Steel Hydro Blasting Machine:

Q: How does the Pressure Jet Stainless Steel Hydro Blasting Machine operate?

A: The machine utilizes high-pressure water jets to remove contaminants, scale, rust, and unwanted materials from surfaces or equipment. It achieves this through a robust pump mechanism housed in a stainless steel frame, delivering focused streams of water for effective cleaning or hydro testing.Q: What applications are suitable for this hydro blasting machine?

A: This machine is ideally suited for hydro blasting, hydro jetting, and hydro testing tasks in sectors such as mining, stone processing, and the chemical industry. Its durable construction makes it reliable for both surface cleaning and pressure-based testing operations.Q: When should I use hydro blasting instead of traditional cleaning methods?

A: Hydro blasting is recommended when standard cleaning techniques are insufficient for removing stubborn deposits or when a thorough, residue-free finish is required. It is particularly beneficial for industrial environments where rapid, effective, and safe cleaning is critical.Q: Where can I purchase or service the Pressure Jet Stainless Steel Hydro Blasting Machine in India?

A: You can obtain this machine throughout India via authorized distributors, suppliers, exporters, manufacturers, traders, and service providers. This wide distribution network ensures fast product access and reliable after-sales support.Q: What is the process for using this machine for hydro testing?

A: To use the machine for hydro testing, you connect it to the equipment under inspection, set required pressure levels, and initiate water flow. The machine then pressurizes the system, enabling leak and strength testing of pipes, tanks, or industrial components.Q: What are the main benefits of using this hydro blasting machine?

A: Key benefits include efficient surface cleaning, reduced need for harsh chemicals, minimized downtime during maintenance, and extended lifespan of industrial equipment. Its stainless steel build and adaptable design ensure long-term service even in demanding operational environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Water Blasting Machine Category

Pressure Jet Semi-Automatic Hydro Blasting Systems

Price 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Weight : Approx weight of bare pump: 430 Kilograms (kg)

Motor Type : IE2 NonFLP Foot Mounted

Application : Mining, Chemical Industry, Stone

Voltage : 415 Volt (v)

10000 PSI Water Blaster

Price 700000 INR / Number

Minimum Order Quantity : 1 Unit

Weight : 930 Kilograms (kg)

Motor Type : IE2 NonFLP Foot Mounted

Application : Mining, Stone, Chemical Industry

Voltage : 415 Volt (v)

Water Blasting Machine

Price 350000 INR / Unit

Minimum Order Quantity : 1 Unit

Weight : Approx weight of bare pump: 60 Kilograms (kg)

Motor Type : IE2 NonFLP Foot Mounted

Application : Stone, Mining, Chemical Industry

Voltage : 220440 Volt (v)

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS