- Home Page

- Company Profile

-

Our Products

- Hydro Jetting Machine

- 1000 Bar 10000 PSI Electric Pressure Washer

- PressureJet Hydro Jetting Pump

- Hydro Jetting System

- Hydro Jetting Machine PressureJet

- PressureJet Hydro Jet Cleaning Machine

- Hydro Jetting Machines

- 20000 PSI Hydro Jetting Machine

- High Pressure Hydro Jetting Equipment

- High Pressure Hydro Jetting Machine

- Hydro Jetting Machine

- Hydro Jetting Equipment

- Hydro Blasting Machine

- 20K Hydroblaster Semi-Automatic Hydroblaster 20 K

- Pressure Jet Hydro Blasting Equipment

- 10000 PSI Hydro Blaster Semi-Automatic Hydro Blaster 10000 PSI

- 10K Water Blaster Semi-Automatic Water Blaster 10 K

- High Pressure Hydro Blasting System

- Pressure Jet Semi-Automatic Hydro Blasting Equipment

- Pressure Jet 3 Phase High Pressure Water Blaster

- 3 Phase Pumps 20000 PSI Pressure Washer

- Water Jet Cleaner

- Hydro Test Pump

- PressureJet Brass, S.s High Pressure Hydrotest Pump (Hydrostatic Test ) , Max Flow Rate: 197

- Stainless Steel Hydro Test Pump

- High Pressure Hydro Test Pump

- Motorized Hydro Test Pump

- Triplex Plunger Hydro Test Pump

- High Pressure Hydrostatic Test Pump

- Hydrostatic Pressure Testing Pump

- Diesel Driven Hydro Test Pump

- High Pressure Hydro Test Pump Unit

- Triplex Plunger Pumps

- Sewer Jetting Pump

- PressureJet EM Series Sewer Jetting Pump Max Flow Rate 267 Lpm

- VA Series Sewer Jetting Pump Max Flow Rate 170 Lpm

- EA Series Sewer Jetting Pump Max Flow Rate 100 Lpm

- PressureJet ES Series Sewer Jetting Pump Max Flow Rate 412 Lpm

- HW Series - Sewer Jetting Pump

- EA Series Sewer Jetting Pump Max Flow Rate 155 LPM

- Pressure Washer

- Jet Cleaners

- Water Blasting Machine

- High Pressure Water Jet Cleaner

- HIGH PRESSURE RECIPROCATING PUMPS

- Hydro Jetting Machine

- Extra Links

- Contact Us

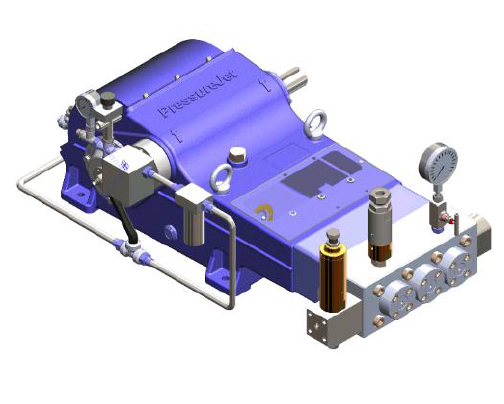

PressureJet High Pressure Reciprocating Pump, For Industrial, Max Flow Rate: 445

Price 150000.00 INR/ Unit

MOQ : 1 Unit

PressureJet High Pressure Reciprocating Pump, For Industrial, Max Flow Rate: 445 Specification

- Flow Rate

- 43 LPM

- Theory

- Reciprocating Pump

- Inlet/Outlet

- BSPF type

- Material

- SS,SG Iron

- Size

- 1286*641*451

- Structure

- Piston Pump

- Height

- 451 Millimeter (mm)

- Power

- Electric

- Weight

- Approx weight of bare pump: 410 Kilograms (kg)

- Pressure

- High Pressure

- Color

- Blue

- Length

- 1286 Millimeter (mm)

- Width

- 641 Millimeter (mm)

- Usage

- Other

- Application

- Other

- Seals Type

- Special Teflon base high pressure seal

PressureJet High Pressure Reciprocating Pump, For Industrial, Max Flow Rate: 445 Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Nhava Sheva ( Mumbai ) , Pipavav , Kandla

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 2 Week

- Packaging Details

- Wooden Box Type Packing

- Main Export Market(s)

- Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About PressureJet High Pressure Reciprocating Pump, For Industrial, Max Flow Rate: 445

PressureJet High Pressure Reciprocating Pump

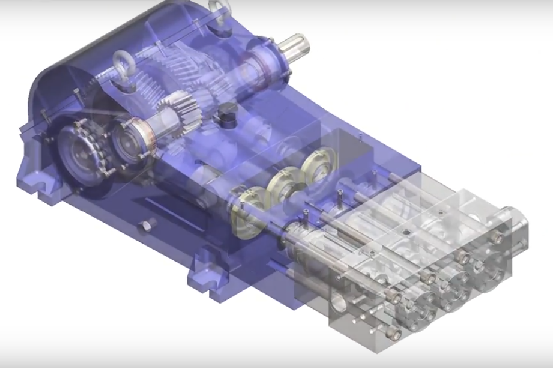

we offer a wide range of the High Pressure Reciprocating Pump, which uses a plunger to move media through a cylindrical chamber. These plunger pumps use a cylindrical mechanism to create a reciprocating motion along an axis, which then builds pressure in a cylinder to force fluid through the pump.

Applications of High Pressure Reciprocating Pump :

- Boiler/heat exchanger/evaporator tube cleaning / pipe cleaning

- Tank cleaning/vessel cleaning

- Water sand blasting

- Hydro testing of tanks, vessels, pipes, valves fittings, hoses systems

- High-pressure cleaning

- Fire fighting

- Sewer jetting

-

Additional Information of High Pressure Reciprocating Pump:

- Pay Mode Terms: T/T (Bank Transfer)

- Port of Dispatch: Ahmedabad, Gujarat

- Production Capacity: 500 pumps per month

- Delivery Time: Approx. delivery time 2 to 3 Weeks, For specific machine delivery time period please contact sales@pressurejet.com

- Packaging Details: Box Type Packaging

Product Details:

|

Minimum Order Quantity |

1 Unit |

|

Material Available |

SS,SG Iron |

|

Max Flow Rate |

Up to 445 LPM |

|

Brand |

Pressure Jet |

|

Automatic Grade |

Semi-Automatic |

|

Condition |

New |

|

Phase |

3 Phase |

Engineered for Heavy-Duty Industrial Applications

This high pressure reciprocating piston pump is built to tackle the toughest industrial cleaning and testing challenges. Its stainless steel and SG Iron construction guarantees resilience under continuous use. The pump's structure, along with advanced Teflon-based seals, minimizes leaks and maximizes operational lifespan, making it suitable for rigorous hydro jetting, blasting, and testing tasks in various industries.

Precision Performance and Easy Installation

With a rated flow of 43 LPM and a high-pressure output, this pump delivers precise fluid control for accurate and consistent results. The standardized BSPF type inlet and outlet connections allow for simple integration into new or existing systems. Its compact design makes setup and maintenance straightforward, whether you are upgrading facility equipment or setting up a new installation.

FAQ's of PressureJet High Pressure Reciprocating Pump, For Industrial, Max Flow Rate: 445:

Q: How does the PressureJet High Pressure Reciprocating Pump operate in industrial environments?

A: This pump utilizes a reciprocating piston mechanism powered by an electric motor, designed to deliver water or other fluids at high pressure. It is especially effective for tasks like hydro jetting, hydro blasting, and hydro testing, ensuring efficient removal or testing with reliable pressure output.Q: What are the main applications of this high pressure pump?

A: The pump is used primarily for hydro jetting, hydro blasting, and hydro test procedures. These activities include industrial cleaning, surface preparation, and pressure testing pipelines or vessels in sectors such as manufacturing, construction, and utilities.Q: When should I consider using this pump for my operations?

A: You should use this pump when your industrial task requires high-pressure cleaning, debris removal, or pressure testing. It is suitable for routine maintenance, emergency cleaning, or stringent testing where consistent, dependable pressure is essential.Q: Where can the PressureJet High Pressure Reciprocating Pump be installed?

A: This pump can be installed in industrial facilities across sectors where high pressure hydro solutions are needed, such as factories, plants, or construction sites. Its compact design allows flexible placement on facility floors or dedicated platforms.Q: What is the installation process for this pump?

A: Installation involves securely placing the pump on a stable surface, connecting the inlet and outlet (BSPF type) to respective pipelines, ensuring proper power supply, and following the manufacturer's safety guidelines for optimal performance and safety.Q: How does the special Teflon base high pressure seal benefit operations?

A: The advanced Teflon-based seals are designed to withstand high pressure and reduce leakage, ensuring operational efficiency and reducing maintenance needs. This significantly extends the lifespan of the pump even in harsh industrial settings.Q: What are the advantages of choosing this pump's stainless steel and SG Iron construction?

A: Stainless steel and SG Iron provide superior structural integrity, excellent corrosion resistance, and durability. This construction makes the pump ideal for long-term industrial use, even in demanding environments, minimizing the risk of damage or frequent repairs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Triplex Plunger Pumps Category

Stainless Steel Semi-Automatic High Pressure Triplex Plunger Pump

Price 100000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Blue

Usage : Other

Theory : Reciprocating Pump

Material : SS Material

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free