- Home Page

- Company Profile

-

Our Products

- Hydro Jetting Machine

- 1000 Bar 10000 PSI Electric Pressure Washer

- PressureJet Hydro Jetting Pump

- Hydro Jetting System

- Hydro Jetting Machine PressureJet

- PressureJet Hydro Jet Cleaning Machine

- Hydro Jetting Machines

- 20000 PSI Hydro Jetting Machine

- High Pressure Hydro Jetting Equipment

- High Pressure Hydro Jetting Machine

- Hydro Jetting Machine

- Hydro Jetting Equipment

- Hydro Blasting Machine

- 20K Hydroblaster Semi-Automatic Hydroblaster 20 K

- Pressure Jet Hydro Blasting Equipment

- 10000 PSI Hydro Blaster Semi-Automatic Hydro Blaster 10000 PSI

- 10K Water Blaster Semi-Automatic Water Blaster 10 K

- High Pressure Hydro Blasting System

- Pressure Jet Semi-Automatic Hydro Blasting Equipment

- Pressure Jet 3 Phase High Pressure Water Blaster

- 3 Phase Pumps 20000 PSI Pressure Washer

- Water Jet Cleaner

- Hydro Test Pump

- PressureJet Brass, S.s High Pressure Hydrotest Pump (Hydrostatic Test ) , Max Flow Rate: 197

- Stainless Steel Hydro Test Pump

- High Pressure Hydro Test Pump

- Motorized Hydro Test Pump

- Triplex Plunger Hydro Test Pump

- High Pressure Hydrostatic Test Pump

- Hydrostatic Pressure Testing Pump

- Diesel Driven Hydro Test Pump

- High Pressure Hydro Test Pump Unit

- Triplex Plunger Pumps

- Sewer Jetting Pump

- PressureJet ES Series Sewer Jetting Pump Max Flow Rate 412 Lpm

- PressureJet EM Series Sewer Jetting Pump Max Flow Rate 267 Lpm

- VA Series Sewer Jetting Pump Max Flow Rate 170 Lpm

- EA Series Sewer Jetting Pump Max Flow Rate 100 Lpm

- HW Series - Sewer Jetting Pump

- EA Series Sewer Jetting Pump Max Flow Rate 155 LPM

- Pressure Washer

- Jet Cleaners

- Water Blasting Machine

- High Pressure Water Jet Cleaner

- HIGH PRESSURE RECIPROCATING PUMPS

- Hydro Jetting Machine

- Extra Links

- Contact Us

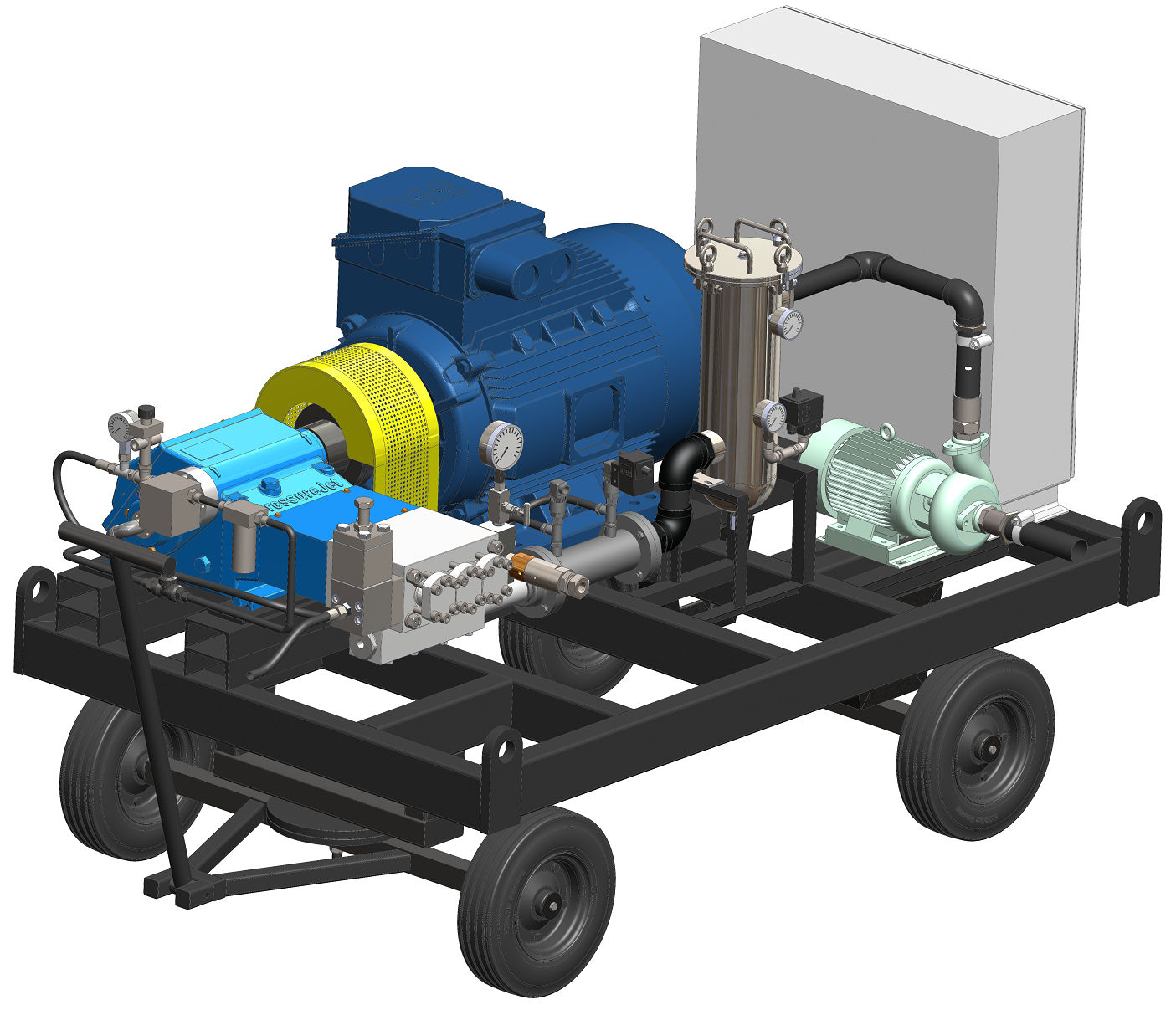

20K Hydroblaster Semi-Automatic Hydroblaster 20 K

Price 250000 INR/ Unit

MOQ : 1 Unit

20K Hydroblaster Semi-Automatic Hydroblaster 20 K Specification

- Usage

- Hydro Blasting , Hydro Jetting , Hydro Test

- Motor Type

- IE2 Non-FLP Foot Mounted

- Size

- 1286*641*451

- Height

- 451 Millimeter (mm)

- Product Type

- Hydro Blasting Machine

- Weight

- Approx weight of bare pump: 410 Kilograms (kg)

- Color

- Blue, yellow , Brown

- Width

- 641 Millimeter (mm)

- Length

- 1286 Millimeter (mm)

- Voltage

- 220-440 Volt (v)

20K Hydroblaster Semi-Automatic Hydroblaster 20 K Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Nhava Sheva ( Mumbai ) , Pipavav , Kandla

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- 10 Units Per Day

- Delivery Time

- 2 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box Type Packing

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Middle East, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About 20K Hydroblaster Semi-Automatic Hydroblaster 20 K

With the help of wide supply and distribution network, our main motive is to offer20K Hydroblaster Semi-Automatic Hydroblaster . The provided machine is mainly used for deburing cutting metal edge, cleaning and removing weld spatter. In order to manufacture this machine, our ingenious professionals use premium quality components with the help of advance techniques. Apart from this, the provided20K Hydroblaster Semi-Automatic Hydroblaster can be purchased in different technical specifications at market leading prices.

Product Details:

|

Body Material |

Cast Iron |

|

Brand |

PressureJet |

|

Automatic Grade |

Semi-Automatic |

|

Condition |

New |

|

Driven Type |

Electric Motor Driven, Diesel Engine Driven |

|

Certification |

ISO 9001 : 2015 |

|

Automation Grade |

Semi-Automatic |

|

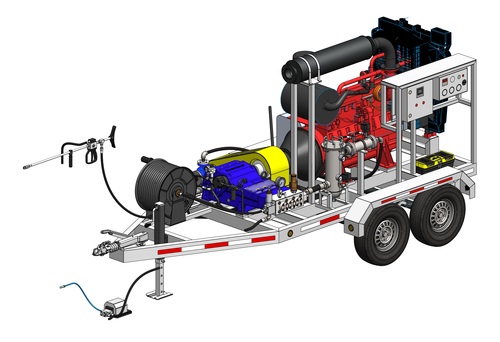

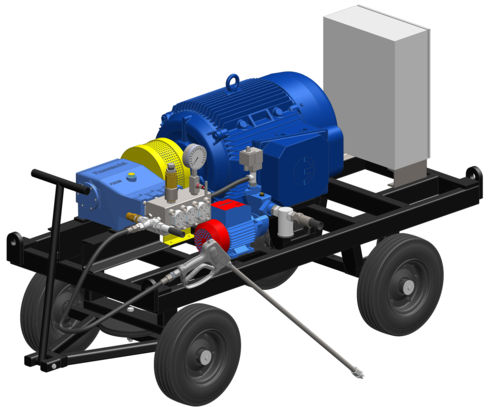

Mounting Type |

Skid Mounted, Trolley Mounted |

|

Color |

Blue |

|

Material |

Stainless steel |

|

Pressure Range in Bar |

250 bar to 1400 bar |

|

Portable |

Yes |

|

Phase |

3 Phase Pumps |

|

Media |

Pure Water |

|

Flow Rate Range in LPM |

15 LPM to 72 LPM |

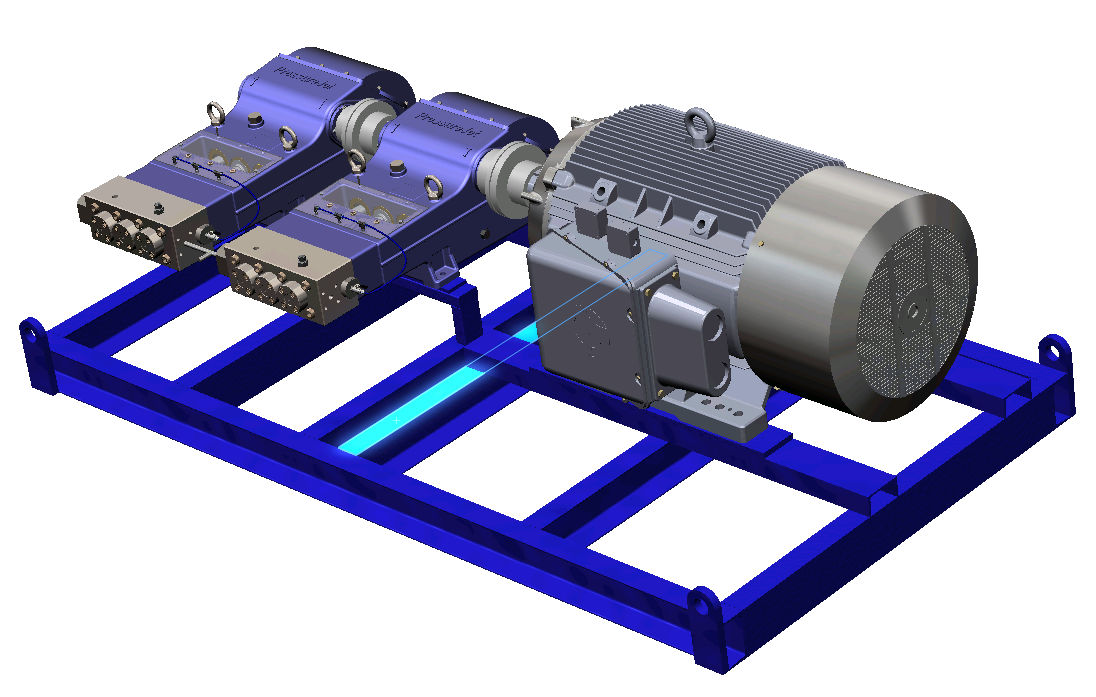

Engineered for Heavy-Duty Surface Preparation

The 20K Hydroblaster Semi-Automatic is specifically engineered to handle demanding industrial tasks like surface preparation and paint removal. Its high-pressure hydro jetting capabilities ensure a clean, smooth finish, ideal for maintenance and renovation projects. The stainless steel construction of liquid end parts delivers long-term reliability even in harsh working environments.

Versatility Across Applications

Designed for multiple operations, the 20K Hydroblaster excels in hydro blasting, hydro testing, and hydro jetting. Its adaptability allows users to tackle a variety of industrial cleaning and preparation needs efficiently. The electric power mode ensures consistent performance while adhering to standard safety and processing protocols.

FAQ's of 20K Hydroblaster Semi-Automatic Hydroblaster 20 K:

Q: How is the 20K Hydroblaster Semi-Automatic typically used?

A: This hydroblaster is primarily used for surface preparation, paint removal, hydro blasting, hydro jetting, and hydro testing in industrial environments. It delivers high-pressure water to efficiently clean surfaces or test equipment integrity.Q: What are the main benefits of using this hydroblaster?

A: The main benefits include quick and thorough removal of paint, scale, or contaminants; reliable hydro testing for safety; and versatile functionality suitable for cleaning and preparing a range of surfaces. Its robust construction ensures durability and longevity even under continuous use.Q: When should I use the 20K Hydroblaster for my operations?

A: You should use this hydroblaster whenever you require industrial-scale surface cleaning or need to prepare surfaces before painting or coating. It is also ideal for situations needing pressure-based testing or maintenance.Q: Where can the 20K Hydroblaster be installed and operated?

A: The machine is designed for use in industrial workshops, construction sites, factories, and maintenance facilities. Its compact design and manageable weight make it suitable for most working environments within India and abroad.Q: What is the process for operating the 20K Hydroblaster?

A: Operators begin by setting up the machine at the required location, connecting it to a power supply (415V electric), and selecting the appropriate nozzle for the application. The system is then activated, delivering high-pressure water for cleaning or testing purposes.Q: How does the electric power mode benefit the user?

A: The electric power mode offers consistent, reliable performance with minimal operational noise and reduced emissions compared to fuel-powered alternatives. It aligns with modern industrial safety and energy efficiency standards.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Hydro Blasting Machine Category

Pressure Jet 3 Phase High Pressure Water Blaster

Price 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Motor Type : IE2 NonFLP Foot Mounted

Height : 451 Millimeter (mm)

Voltage : 220440 Volt (v)

Length : 1286 Millimeter (mm)

Pressure Jet Hydro Blasting Equipment

Price 750000 INR / Unit

Minimum Order Quantity : 1 Unit

Motor Type : IE2 NonFLP Foot Mounted

Height : 331 Millimeter (mm)

Voltage : 220440 Volt (v)

Length : 948 Millimeter (mm)

3 Phase Pumps 20000 PSI Pressure Washer

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Unit

Motor Type : IE2 NonFLP Foot Mounted

Height : 641 Millimeter (mm)

Voltage : 220440 Volt (v)

Length : 1286 Millimeter (mm)

High Pressure Hydro Blasting System

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Motor Type : IE2 NonFLP Foot Mounted

Height : 215 Millimeter (mm)

Voltage : 220440 Volt (v)

Length : 510 Millimeter (mm)

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS