- Home Page

- Company Profile

-

Our Products

- Hydro Jetting Machine

- 1000 Bar 10000 PSI Electric Pressure Washer

- PressureJet Hydro Jetting Pump

- Hydro Jetting System

- Hydro Jetting Machine PressureJet

- PressureJet Hydro Jet Cleaning Machine

- Hydro Jetting Machines

- 20000 PSI Hydro Jetting Machine

- High Pressure Hydro Jetting Equipment

- High Pressure Hydro Jetting Machine

- Hydro Jetting Machine

- Hydro Jetting Equipment

- Hydro Blasting Machine

- 20K Hydroblaster Semi-Automatic Hydroblaster 20 K

- Pressure Jet Hydro Blasting Equipment

- 10000 PSI Hydro Blaster Semi-Automatic Hydro Blaster 10000 PSI

- 10K Water Blaster Semi-Automatic Water Blaster 10 K

- High Pressure Hydro Blasting System

- Pressure Jet Semi-Automatic Hydro Blasting Equipment

- Pressure Jet 3 Phase High Pressure Water Blaster

- 3 Phase Pumps 20000 PSI Pressure Washer

- Water Jet Cleaner

- Hydro Test Pump

- Diesel Driven Hydro Test Pump

- High Pressure Hydro Test Pump

- Motorized Hydro Test Pump

- Triplex Plunger Hydro Test Pump

- High Pressure Hydrostatic Test Pump

- Hydrostatic Pressure Testing Pump

- PressureJet Brass, S.s High Pressure Hydrotest Pump (Hydrostatic Test ) , Max Flow Rate: 197

- Stainless Steel Hydro Test Pump

- High Pressure Hydro Test Pump Unit

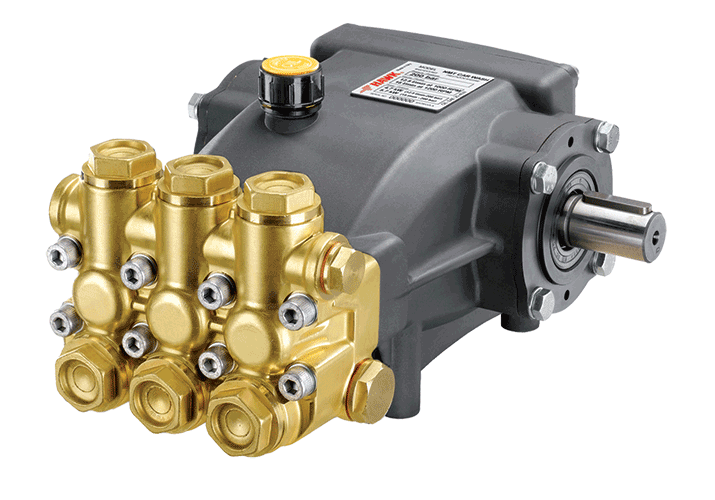

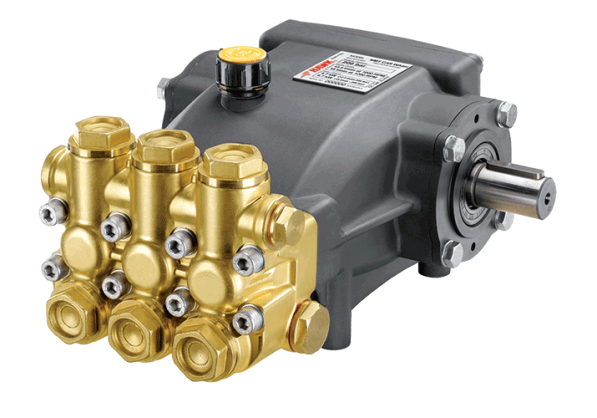

- Triplex Plunger Pumps

- Sewer Jetting Pump

- PressureJet EM Series Sewer Jetting Pump Max Flow Rate 267 Lpm

- VA Series Sewer Jetting Pump Max Flow Rate 170 Lpm

- EA Series Sewer Jetting Pump Max Flow Rate 100 Lpm

- PressureJet ES Series Sewer Jetting Pump Max Flow Rate 412 Lpm

- HW Series - Sewer Jetting Pump

- EA Series Sewer Jetting Pump Max Flow Rate 155 LPM

- Pressure Washer

- Jet Cleaners

- Water Blasting Machine

- High Pressure Water Jet Cleaner

- HIGH PRESSURE RECIPROCATING PUMPS

- Hydro Jetting Machine

- Extra Links

- Contact Us

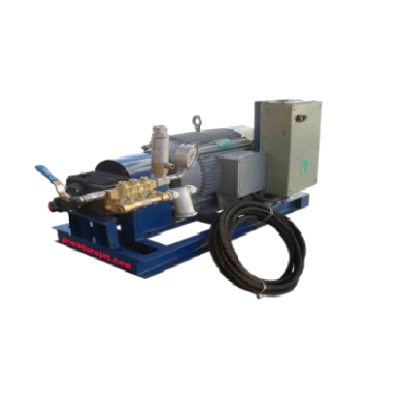

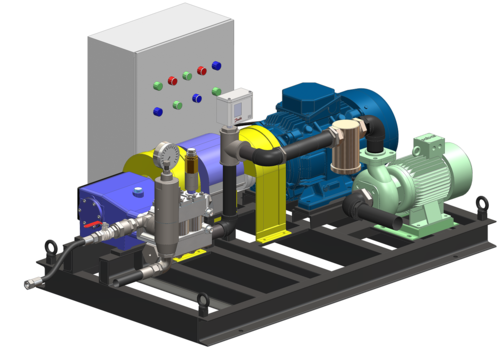

Motorized Hydro Test Pump

Price 200000.00 INR/ Unit

MOQ : 1 Unit

Motorized Hydro Test Pump Specification

- Flow Rate

- 15 LPM

- Inlet/Outlet

- BSPF

- Theory

- Reciprocating Pump

- Material

- SS, Brass, SG Iron

- Structure

- Piston Pump

- Size

- 45*27*27

- Height

- 27 Inch (in)

- Power

- Electric

- Weight

- 170 Kilograms (kg)

- Pressure

- High Pressure

- Color

- Black

- Usage

- Water, Automobile

- Length

- 45 Inch (in)

- Width

- 27 Inch (in)

- Application

- Fire, Sewage

- Seals Type

- Mechanical

Motorized Hydro Test Pump Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Nhava Sheva ( Mumbai ) , Pipavav , Kandla

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- 100 Units Per Week

- Delivery Time

- 2 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box Type Packing

- Main Export Market(s)

- Australia, Western Europe, Middle East, Africa, Central America, South America, Asia, Eastern Europe, North America

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

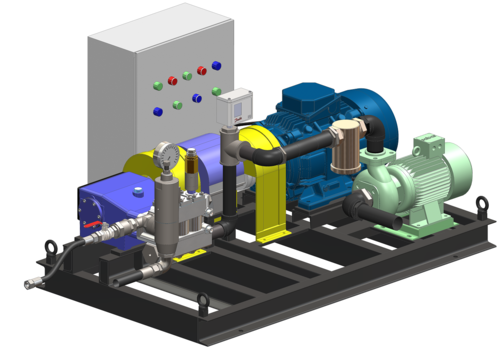

About Motorized Hydro Test Pump

Product Details:

|

Condition |

New |

|

Brand |

Hawk |

|

Driven Type |

Electric motor driven, Diesel engine driven |

|

Max Flow Rate |

15 LPM |

|

Rpm |

For 50 Hz - 1450 RPM |

|

Product Tags |

High Pressure Hydro Testing Pumps, Electric motor Driven Hydro Testing Pump, Hydro Testing Pump |

|

Product Name Tags |

Hydrostatic Pressure Testing Pump, Diesel Engine Driven Hydro Testing Pump |

|

Pressure |

250 bar |

|

Power Supply |

Available in 50 Hz and 60 Hz |

|

Portable |

Yes |

|

Mounting Option |

Trolly Mounted, Skid Mounted |

|

Media |

Pure Water |

|

Material Available |

SS, Brass, SG Iron |

Rugged Construction for Versatile Applications

Engineered from stainless steel, brass, and SG iron, this motorized hydro test pump stands up to rigorous industrial use. Its high-pressure capacity and piston-driven design make it perfect for applications in fire testing, sewage treatment, and automotive lines.

Efficient and Reliable Performance

With a 15 LPM flow rate and electric drive, this pump ensures steady pressure for accurate hydro testing. Its mechanical seals prevent leakage, making every test safe and effective while minimizing maintenance downtime.

FAQ's of Motorized Hydro Test Pump:

Q: How is the Motorized Hydro Test Pump used in automobile and fire safety applications?

A: This pump is utilized for high-pressure hydrostatic testing of pipelines, valves, and vessels in automobiles and fire safety systems, ensuring their integrity and safety compliance.Q: What materials are used in the construction of this pump, and why are they important?

A: The pump features stainless steel, brass, and SG iron, chosen for their strength and corrosion resistance, which prolongs equipment life and ensures optimal performance during rigorous testing.Q: When should this hydro test pump be employed during a maintenance process?

A: It is typically used after installation or repair, before system commissioning, to check for leaks or weaknesses in pipelines and pressure vessels.Q: Where can the Motorized Hydro Test Pump be installed and operated?

A: Owing to its compact 45*27*27-inch size and 170 kg weight, it can be conveniently installed in workshops, industrial sites, or testing facilities across India.Q: What is the process for operating the pump for hydrostatic testing?

A: Connect the inlet and outlet using BSPF fittings, fill the system with water, power on the electric drive, and gradually pressurize to the required level, monitoring for leaks or pressure drops.Q: How does the pump's mechanical seal benefit users compared to conventional seals?

A: Mechanical seals offer superior leak prevention and reduce maintenance frequency, resulting in a more reliable and cost-effective operation over time.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Hydro Test Pump Category

Triplex Plunger Hydro Test Pump

Price 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Structure : Piston Pump

Theory : Reciprocating Pump

Weight : Approx weight of bare pump: 85 Kilograms (kg)

Size : 498*360*198

Stainless Steel Hydro Test Pump

Price 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Structure : Piston Pump

Theory : Reciprocating Pump

Weight : 120 Kilograms (kg)

Size : 33*24*24

High Pressure Hydro Test Pump Unit

Price 200000 INR

Minimum Order Quantity : 1 Unit

Structure : Piston Pump

Theory : Reciprocating Pump

Weight : Approx weight of bare pump: 85 Kilograms (kg)

Size : 498*360*198

High Pressure Hydrostatic Test Pump

Price 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Structure : Piston Pump

Theory : Reciprocating Pump

Weight : 180 Kilograms (kg)

Size : 48*30*30

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS