- Home Page

- Company Profile

-

Our Products

- Hydro Jetting Machine

- 1000 Bar 10000 PSI Electric Pressure Washer

- PressureJet Hydro Jetting Pump

- Hydro Jetting System

- Hydro Jetting Machine PressureJet

- PressureJet Hydro Jet Cleaning Machine

- Hydro Jetting Machines

- 20000 PSI Hydro Jetting Machine

- High Pressure Hydro Jetting Equipment

- High Pressure Hydro Jetting Machine

- Hydro Jetting Machine

- Hydro Jetting Equipment

- Hydro Blasting Machine

- 20K Hydroblaster Semi-Automatic Hydroblaster 20 K

- Pressure Jet Hydro Blasting Equipment

- 10000 PSI Hydro Blaster Semi-Automatic Hydro Blaster 10000 PSI

- 10K Water Blaster Semi-Automatic Water Blaster 10 K

- High Pressure Hydro Blasting System

- Pressure Jet Semi-Automatic Hydro Blasting Equipment

- Pressure Jet 3 Phase High Pressure Water Blaster

- 3 Phase Pumps 20000 PSI Pressure Washer

- Water Jet Cleaner

- Hydro Test Pump

- PressureJet Brass, S.s High Pressure Hydrotest Pump (Hydrostatic Test ) , Max Flow Rate: 197

- Stainless Steel Hydro Test Pump

- High Pressure Hydro Test Pump

- Motorized Hydro Test Pump

- Triplex Plunger Hydro Test Pump

- High Pressure Hydrostatic Test Pump

- Hydrostatic Pressure Testing Pump

- Diesel Driven Hydro Test Pump

- High Pressure Hydro Test Pump Unit

- Triplex Plunger Pumps

- Sewer Jetting Pump

- PressureJet EM Series Sewer Jetting Pump Max Flow Rate 267 Lpm

- VA Series Sewer Jetting Pump Max Flow Rate 170 Lpm

- EA Series Sewer Jetting Pump Max Flow Rate 100 Lpm

- PressureJet ES Series Sewer Jetting Pump Max Flow Rate 412 Lpm

- HW Series - Sewer Jetting Pump

- EA Series Sewer Jetting Pump Max Flow Rate 155 LPM

- Pressure Washer

- Jet Cleaners

- Water Blasting Machine

- High Pressure Water Jet Cleaner

- HIGH PRESSURE RECIPROCATING PUMPS

- Hydro Jetting Machine

- Extra Links

- Contact Us

Stainless Steel Hydro Test Pump

Price 200000.00 INR/ Unit

MOQ : 1 Unit

Stainless Steel Hydro Test Pump Specification

- Theory

- Reciprocating Pump

- Flow Rate

- 14 LPM

- Inlet/Outlet

- BSPF

- Material

- Metal

- Structure

- Piston Pump

- Size

- 33*24*24

- Power

- Electric

- Height

- 24 Inch (in)

- Weight

- 120 Kilograms (kg)

- Pressure

- High Pressure

- Color

- Black

- Width

- 24 Inch (in)

- Length

- 33 Inch (in)

- Usage

- Water, Automobile

- Application

- Fire, Sewage

- Seals Type

- Durable Fiber Impregnated Buna-n Seal

Stainless Steel Hydro Test Pump Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Nhava Sheva ( Mumbai ) , Pipavav , Kandla

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- 100 Units Per Week

- Delivery Time

- 2-3 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box Type Packing

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Africa, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Stainless Steel Hydro Test Pump

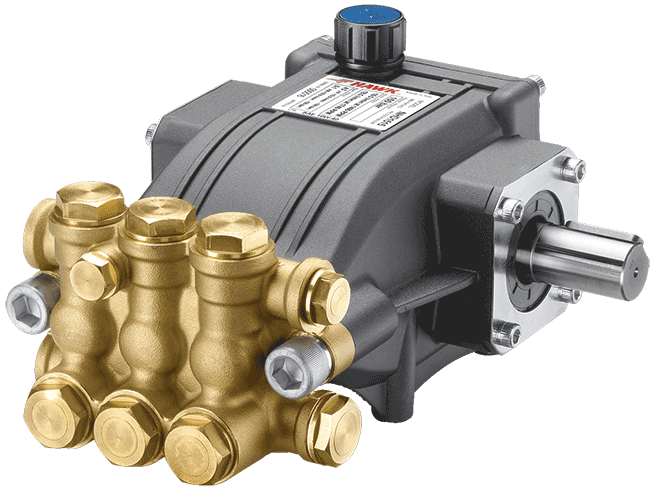

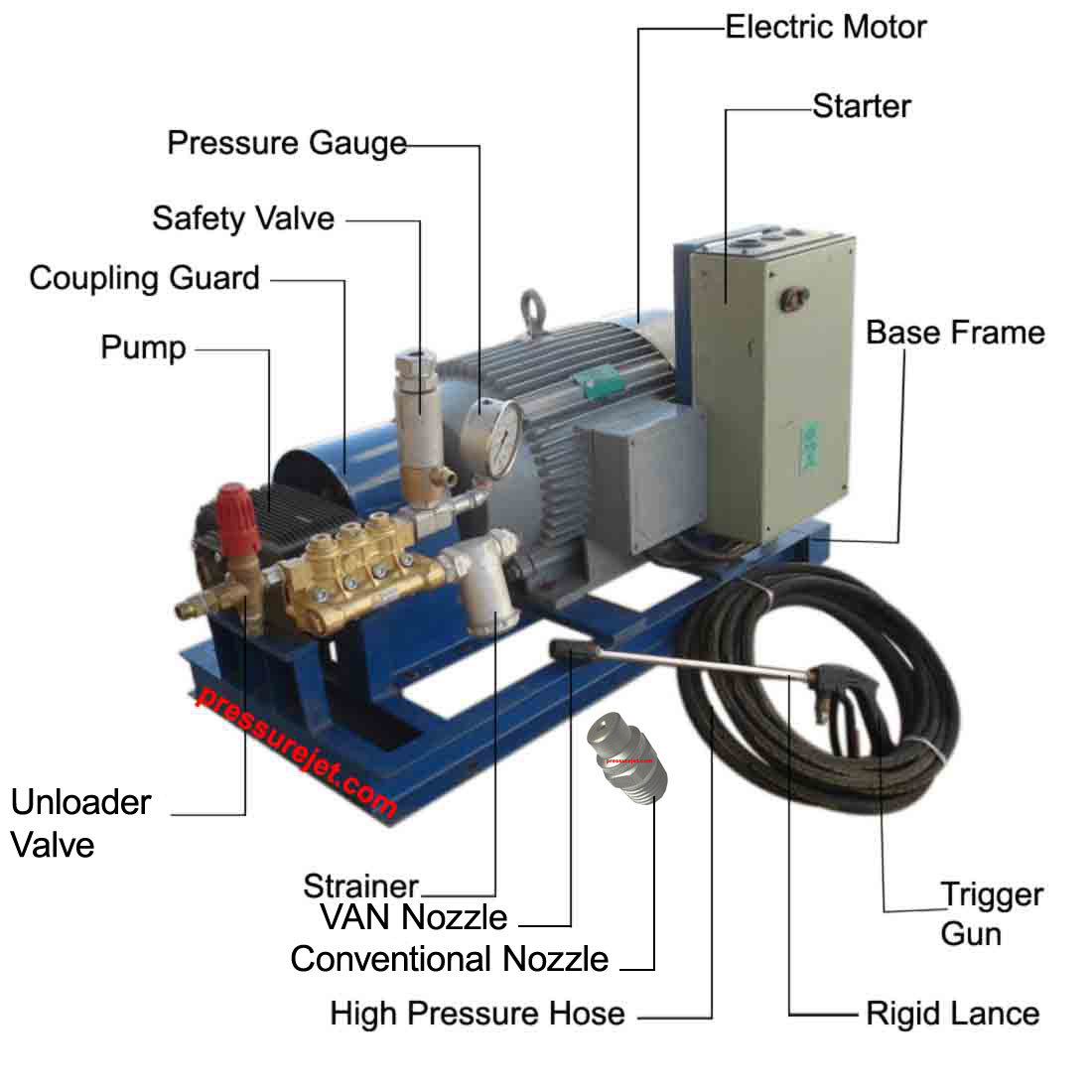

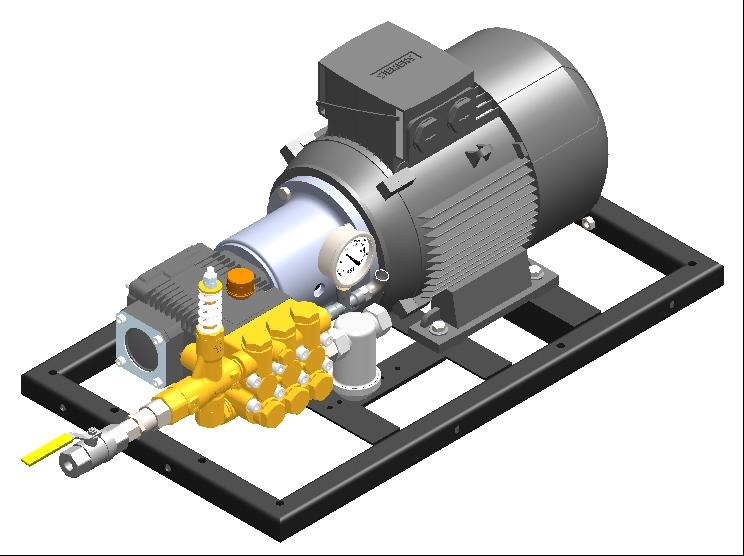

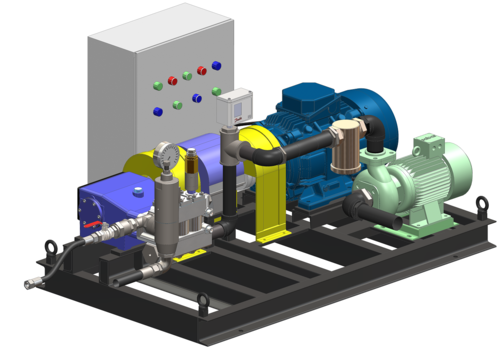

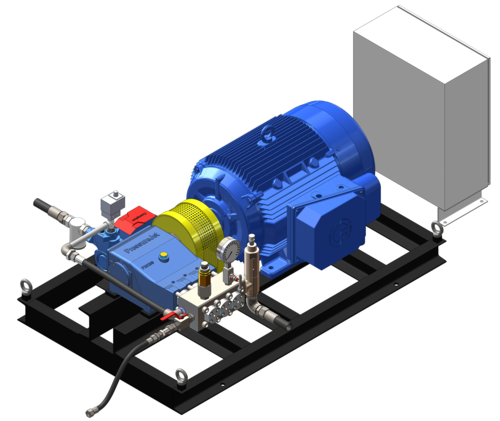

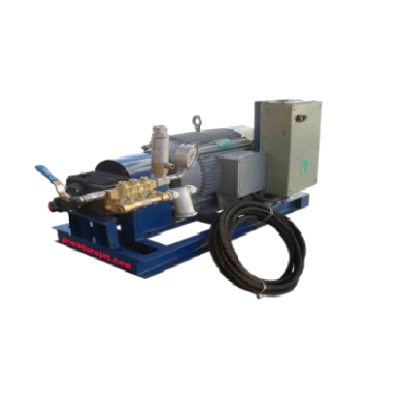

We take huge pride to introduce ourselves as one of the famous manufacturers, suppliers and exporters of Stainless Steel Hydro Test Pump. The provided product is complete with drive, safety & control systems and is used for different applications of cleaning. It is available in various designs and with a various of features, which make it versatile in nature. Our Stainless Steel Hydro Test Pump find application in various industries like cement plants, hospitals, power plants, textile units, coal field and mines.

Product Details:

|

Condition |

New |

|

Brand |

Hawk |

|

Driven Type |

Electric motor driven, Diesel engine driven |

|

Rpm |

For 50 Hz - 1450 RPM |

|

Product Tags |

High Pressure Hydro Testing Pumps, Electric motor Driven Hydro Testing Pump, Hydro Testing Pump |

|

Product Name Tags |

Hydrostatic Pressure Testing Pump, Diesel Engine Driven Hydro Testing Pump |

|

Pressure Range |

140 bar |

|

Power Supply |

Available in 50 Hz and 60 Hz |

|

Portable |

Yes |

|

Mounting Option |

Trolly Mounted, Skid Mounted |

|

Media |

Pure Water |

|

Material Available |

SS, Brass, SG Iron |

High-Pressure Stainless Steel Reciprocating Pump

Engineered for precision, the Stainless Steel Hydro Test Pump delivers outstanding performance under demanding conditions. Its reciprocating piston mechanism supports consistent high-pressure output, making it suitable for hydrostatic testing across various industries. The durable seals and electric power source guarantee long service life and operational efficiency.

Versatile Applications and Reliable Design

This pump fits diverse applications, including fire safety checks, sewage system validation, water line integrity testing, and automotive component testing. Thanks to its robust structure and industry-grade materials, the pump stands up to rigorous use while maintaining safety and reliability in sensitive operations.

FAQ's of Stainless Steel Hydro Test Pump:

Q: How does the Stainless Steel Hydro Test Pump operate during a hydrostatic test?

A: The pump uses a reciprocating piston mechanism to pressurize water or other fluids within pipelines or equipment, helping to verify their structural integrity by detecting leaks or weaknesses under controlled high-pressure conditions.Q: What makes the durable fiber impregnated Buna-n seals advantageous for this pump?

A: These specially designed seals provide exceptional resistance to wear, chemicals, and high pressures, ensuring a longer operational lifespan while preventing leaks during intensive hydro testing procedures.Q: When should the hydro test pump be used in automobile or fire safety applications?

A: The pump is best utilized during routine maintenance, safety inspections, or before commissioning new systems to ensure that critical water, fire suppression, or hydraulic systems are free from leaks or weaknesses.Q: Where can this hydro test pump be installed or operated?

A: Its rugged build and manageable dimensions allow deployment in industrial settings, automotive workshops, fire safety systems, sewage testing locations, and construction sites requiring hydrostatic testing.Q: What is the process for setting up the pump before testing?

A: Connect the BSPF inlet and outlet to the system requiring testing, ensure the pump is properly filled with water, check all seals, and then power up the unit for operation, monitoring pressure with compatible gauges throughout the process.Q: What are the key benefits of using this stainless steel hydro test pump?

A: The primary advantages include high pressure capability, reliable sealing, consistent flow rate, electric operation for ease of use, and a robust metal construction that ensures durability and low maintenance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Hydro Test Pump Category

Triplex Plunger Hydro Test Pump

Price 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Length : 498 Millimeter (mm)

Usage : Water, Automobile, Other

Inlet/Outlet : BSPF type

Pressure : High Pressure

Hydrostatic Pressure Testing Pump

Price 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Length : 686 Millimeter (mm)

Usage : Water, Other

Inlet/Outlet : BSPF

Pressure : High Pressure

Motorized Hydro Test Pump

Price 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Length : 45 Inch (in)

Usage : Water, Automobile, Other

Inlet/Outlet : BSPF

Pressure : High Pressure

PressureJet Brass, S.s High Pressure Hydrotest Pump (Hydrostatic Test ) , Max Flow Rate: 197

Price 100000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Length : 1192 Millimeter (mm)

Usage : Water, Other

Inlet/Outlet : BSPF

Pressure : High Pressure

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free