- Home Page

- Company Profile

-

Our Products

- Hydro Jetting Machine

- 1000 Bar 10000 PSI Electric Pressure Washer

- PressureJet Hydro Jetting Pump

- Hydro Jetting System

- Hydro Jetting Machine PressureJet

- PressureJet Hydro Jet Cleaning Machine

- Hydro Jetting Machines

- 20000 PSI Hydro Jetting Machine

- High Pressure Hydro Jetting Equipment

- High Pressure Hydro Jetting Machine

- Hydro Jetting Machine

- Hydro Jetting Equipment

- Hydro Blasting Machine

- 20K Hydroblaster Semi-Automatic Hydroblaster 20 K

- Pressure Jet Hydro Blasting Equipment

- 10000 PSI Hydro Blaster Semi-Automatic Hydro Blaster 10000 PSI

- 10K Water Blaster Semi-Automatic Water Blaster 10 K

- High Pressure Hydro Blasting System

- Pressure Jet Semi-Automatic Hydro Blasting Equipment

- Pressure Jet 3 Phase High Pressure Water Blaster

- 3 Phase Pumps 20000 PSI Pressure Washer

- Water Jet Cleaner

- Hydro Test Pump

- PressureJet Brass, S.s High Pressure Hydrotest Pump (Hydrostatic Test ) , Max Flow Rate: 197

- Stainless Steel Hydro Test Pump

- High Pressure Hydro Test Pump

- Motorized Hydro Test Pump

- Triplex Plunger Hydro Test Pump

- High Pressure Hydrostatic Test Pump

- Hydrostatic Pressure Testing Pump

- Diesel Driven Hydro Test Pump

- High Pressure Hydro Test Pump Unit

- Triplex Plunger Pumps

- Sewer Jetting Pump

- PressureJet EM Series Sewer Jetting Pump Max Flow Rate 267 Lpm

- VA Series Sewer Jetting Pump Max Flow Rate 170 Lpm

- EA Series Sewer Jetting Pump Max Flow Rate 100 Lpm

- PressureJet ES Series Sewer Jetting Pump Max Flow Rate 412 Lpm

- HW Series - Sewer Jetting Pump

- EA Series Sewer Jetting Pump Max Flow Rate 155 LPM

- Pressure Washer

- Jet Cleaners

- Water Blasting Machine

- High Pressure Water Jet Cleaner

- HIGH PRESSURE RECIPROCATING PUMPS

- Hydro Jetting Machine

- Extra Links

- Contact Us

Hydrostatic Pressure Testing Pump

Price 200000.00 INR/ Unit

MOQ : 1 Unit

Hydrostatic Pressure Testing Pump Specification

- Inlet/Outlet

- BSPF

- Flow Rate

- 35 LPM

- Theory

- Reciprocating Pump

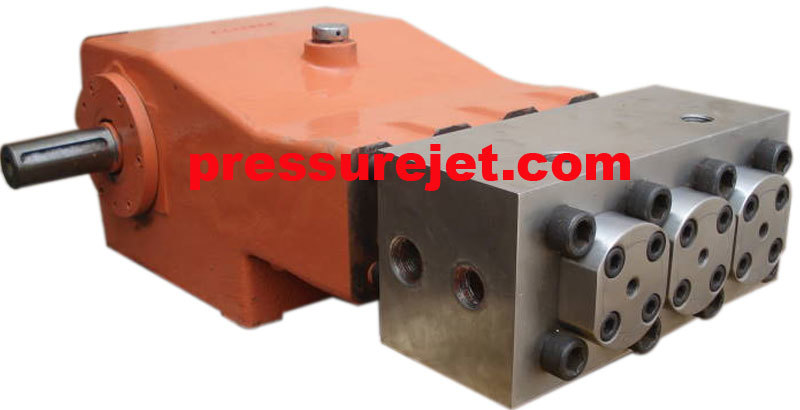

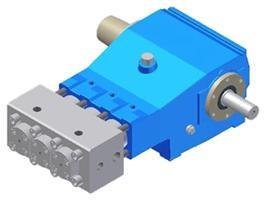

- Material

- SS, Brass, SG Iron

- Structure

- Piston Pump

- Size

- 686*331*196

- Power

- Electric

- Height

- 196 Millimeter (mm)

- Weight

- Approx weight of bare pump: 85 Kilograms (kg)

- Color

- Blue, orange

- Pressure

- High Pressure

- Width

- 331 Millimeter (mm)

- Length

- 686 Millimeter (mm)

- Usage

- Water

- Application

- Fire

- Seals Type

- PTFE Aramide

Hydrostatic Pressure Testing Pump Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Nhava Sheva ( Mumbai ) , Pipavav , Kandla

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 2-3 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box Type Packing

- Main Export Market(s)

- South America, Eastern Europe, Western Europe, Middle East, Central America, Africa, North America, Australia, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Hydrostatic Pressure Testing Pump

The Hydrostatic Pressure Testing Pump is made available by us for use in the various commercial and industrial applications. A hydrostatic pressure test, or hydro test, involves putting the pump casing under pressure that is considerably greater than the actual operating pressure to ensure that the casing is strong enough to withstand operating pressures. Hydrostatic testing is used to find leaks in pressurized systems. Pipelines, plumbing, boilers, fuel tanks, and gas cylinders are commonly tested with this method. It can be done on your homes sewer line to see if any leaks are present. The offered Hydrostatic Pressure Testing Pump is very useful.

Product Details:

|

Driven Type |

Electric motor driven, Diesel engine driven |

|

Max Flow Rate |

35 LPM |

|

Rpm |

For 50 Hz - 1450 RPM |

|

Product Tags |

High Pressure Hydro Testing Pumps, Electric motor Driven Hydro Testing Pump, Hydro Testing Pump |

|

Product Name Tags |

Hydrostatic Pressure Testing Pump, Diesel Engine Driven Hydro Testing Pump |

|

Pressure Range |

390 bar |

|

Power Supply |

Available in 50 Hz and 60 Hz |

|

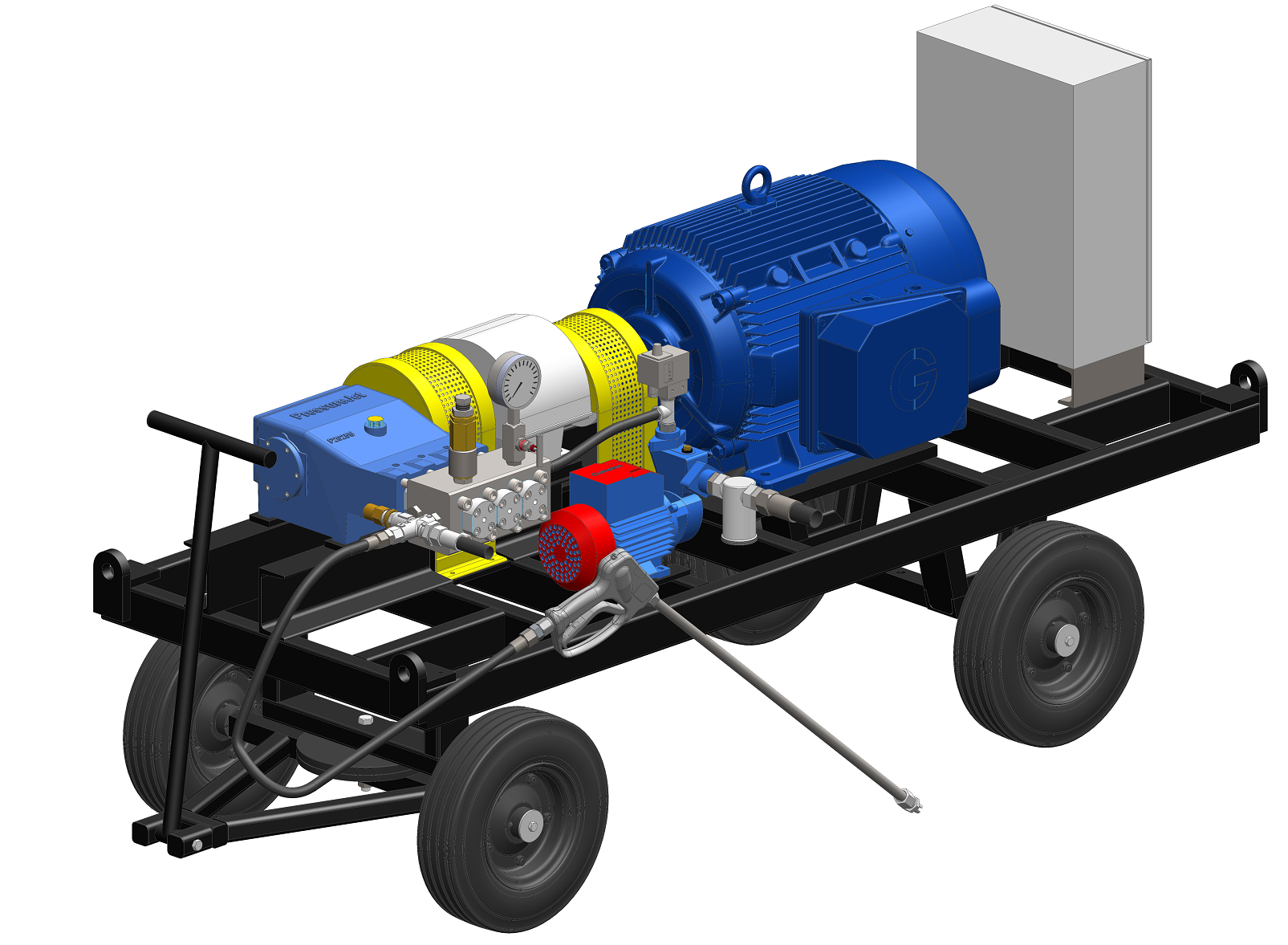

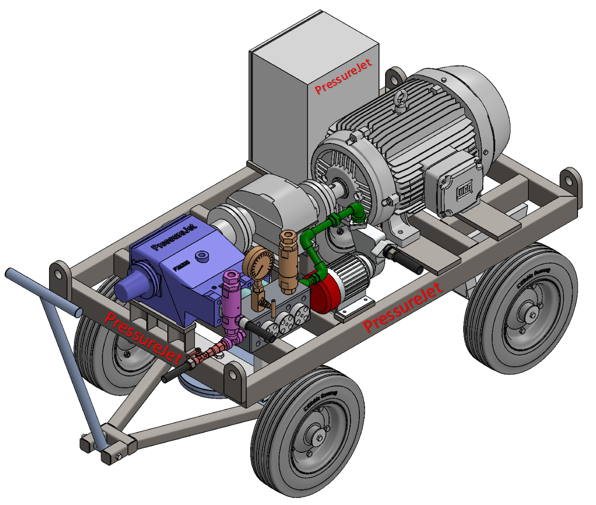

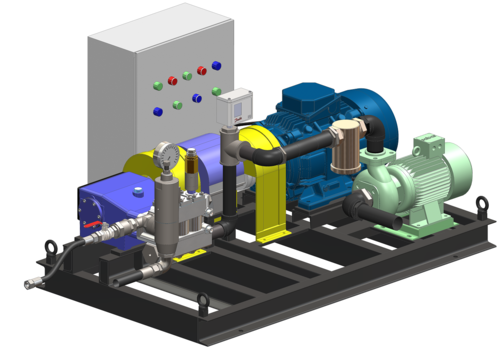

Portable |

Yes |

|

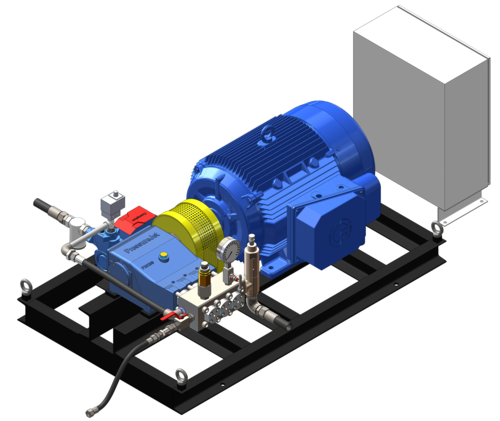

Mounting Option |

Trolly Mounted, Skid Mounted |

|

Media |

Pure Water |

|

Material Available |

SS, Brass, SG Iron |

High-Performance Hydrostatic Testing Solution

Designed for versatility and durability, this pump ensures accurate hydrostatic pressure testing across a range of industrial applications. Its SS, Brass, and SG Iron construction offers excellent corrosion resistance, while the advanced piston mechanism guarantees consistent flow and high-precision results. Whether assessing pipelines or fire safety systems, this electric-powered unit is engineered for reliable, long-term use.

Precision Engineering and Reliable Operation

With dimensions of 686x331x196 mm and a sturdy build, the pump fits seamlessly into various testing environments. The PTFE Aramide seals and BSPF connections provide leak-free operation, ensuring both the safety and integrity of the systems under testing. Its user-friendly controls facilitate easy setup, making it a preferred choice among professionals in water and fire application fields.

FAQ's of Hydrostatic Pressure Testing Pump:

Q: How does the hydrostatic pressure testing pump function in industrial environments?

A: This pump operates by utilizing electric power to drive a reciprocating piston, pressurizing water that is then introduced into pipelines, steam coils, or cylinders. It safely raises internal pressures to test a system's strength and leak resistance.Q: What applications is this pump suitable for?

A: The pump is suited for water-based tests in cross-country pipelines, steam coil hydro testing, cylinder hydro testing, and fire systems. It is ideal for industrial safety checks and performance assessments due to its high-pressure and precision capabilities.Q: Where can the hydrostatic pressure testing pump be used?

A: It can be utilized on-site in industries like oil and gas, power generation, fire safety, and manufacturing plants across India. Its portable, robust design makes it practical for both indoor and outdoor conditions.Q: What is the process for using this testing pump?

A: Connect the system to be tested to the pump's BSPF inlet/outlet ports, fill with water, and gradually increase the electric-powered pressure using the control mechanism. Monitor for leaks or deformations to evaluate system integrity.Q: When is hydrostatic pressure testing recommended?

A: Hydrostatic pressure testing is crucial before commissioning new pipelines, periodically during maintenance, and after repairs to ensure safety standards are met and leaks are detected early.Q: What are the benefits of using a pump with PTFE Aramide seals and SS, Brass, SG Iron construction?

A: PTFE Aramide seals offer outstanding leak protection and chemical resistance, while SS, Brass, and SG Iron ensure long-term durability, corrosion resistance, and reliable performance-even under high-pressure conditions.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Hydro Test Pump Category

PressureJet Brass, S.s High Pressure Hydrotest Pump (Hydrostatic Test ) , Max Flow Rate: 197

Price 100000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : SS,Brass,SG Iron

Seals Type : Special Teflon base high pressure seal

Color : Blue

Width : 592 Millimeter (mm)

Triplex Plunger Hydro Test Pump

Price 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : SS, Brass, SG Iron

Seals Type : Mechanical

Color : Blue

Width : 360 Millimeter (mm)

Stainless Steel Hydro Test Pump

Price 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Metal

Seals Type : Durable Fiber Impregnated Bunan Seal

Color : Black

Width : 24 Inch (in)

Diesel Driven Hydro Test Pump

Price 400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : SS, Brass, SG Iron

Seals Type : Mechanical

Color : Blue, yellow

Width : 80 Inch (in)

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS