- Home Page

- Company Profile

-

Our Products

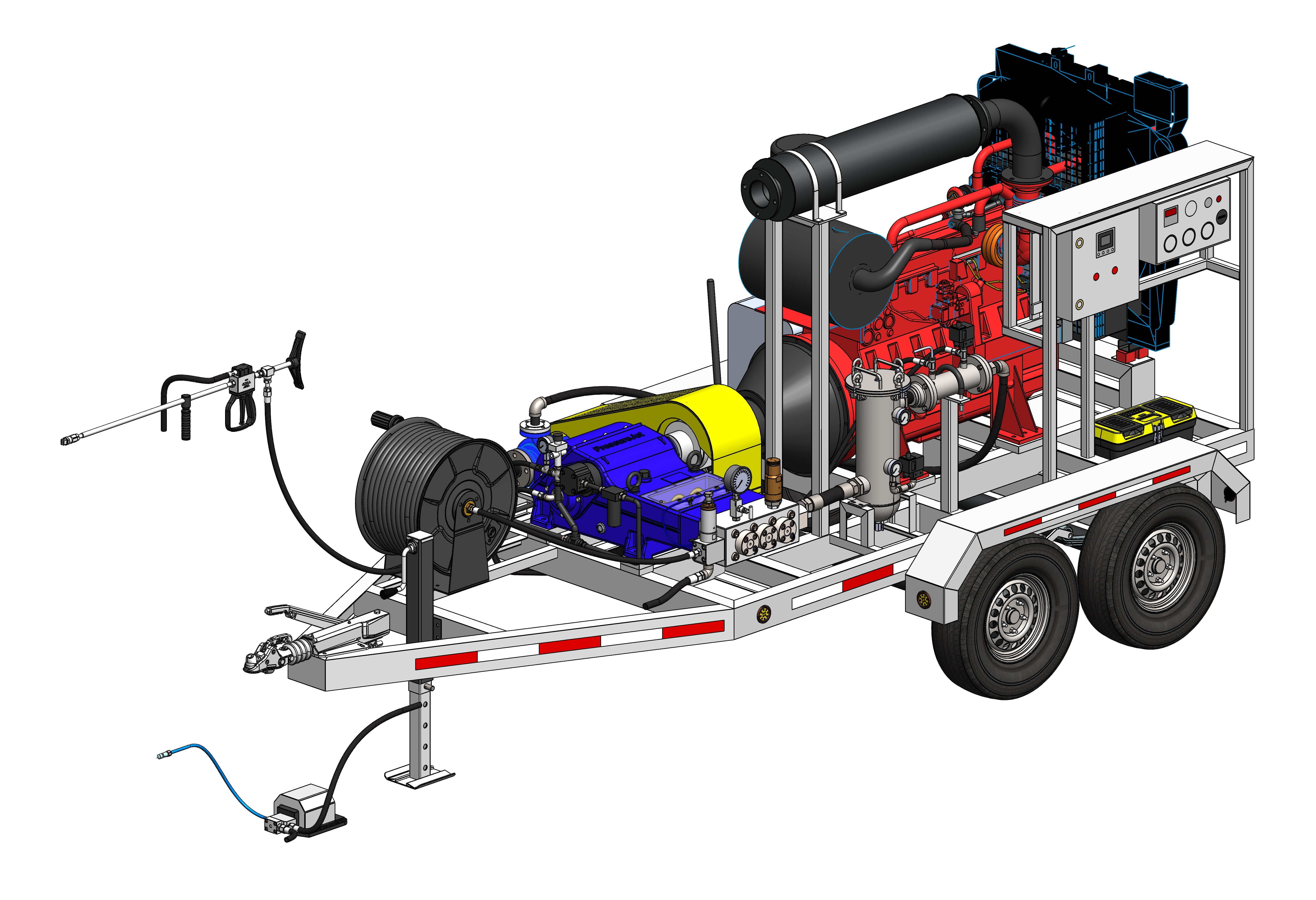

- Hydro Jetting Machine

- 1000 Bar 10000 PSI Electric Pressure Washer

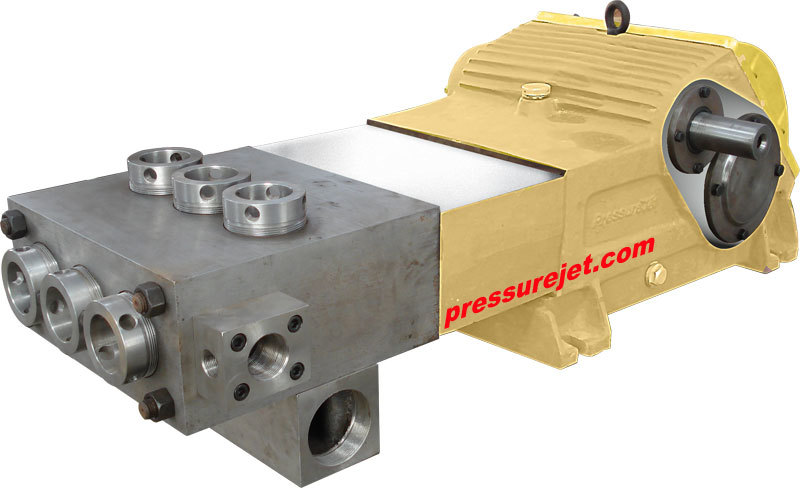

- PressureJet Hydro Jetting Pump

- Hydro Jetting System

- Hydro Jetting Machine PressureJet

- PressureJet Hydro Jet Cleaning Machine

- Hydro Jetting Machines

- 20000 PSI Hydro Jetting Machine

- High Pressure Hydro Jetting Equipment

- High Pressure Hydro Jetting Machine

- Hydro Jetting Machine

- Hydro Jetting Equipment

- Hydro Blasting Machine

- 20K Hydroblaster Semi-Automatic Hydroblaster 20 K

- Pressure Jet Hydro Blasting Equipment

- 10000 PSI Hydro Blaster Semi-Automatic Hydro Blaster 10000 PSI

- 10K Water Blaster Semi-Automatic Water Blaster 10 K

- High Pressure Hydro Blasting System

- Pressure Jet Semi-Automatic Hydro Blasting Equipment

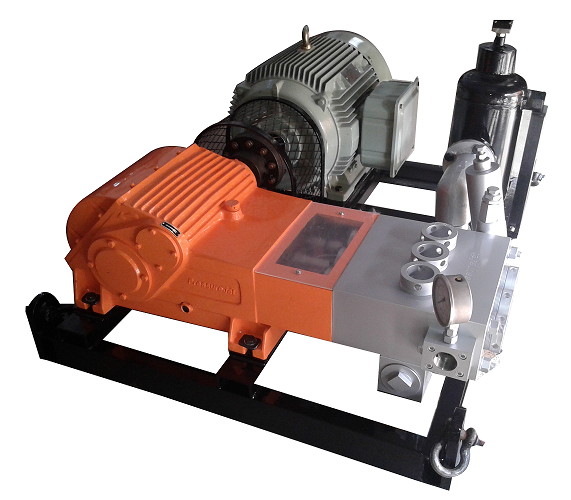

- Pressure Jet 3 Phase High Pressure Water Blaster

- 3 Phase Pumps 20000 PSI Pressure Washer

- Water Jet Cleaner

- Hydro Test Pump

- PressureJet Brass, S.s High Pressure Hydrotest Pump (Hydrostatic Test ) , Max Flow Rate: 197

- Stainless Steel Hydro Test Pump

- High Pressure Hydro Test Pump

- Motorized Hydro Test Pump

- Triplex Plunger Hydro Test Pump

- High Pressure Hydrostatic Test Pump

- Hydrostatic Pressure Testing Pump

- Diesel Driven Hydro Test Pump

- High Pressure Hydro Test Pump Unit

- Triplex Plunger Pumps

- Sewer Jetting Pump

- PressureJet EM Series Sewer Jetting Pump Max Flow Rate 267 Lpm

- VA Series Sewer Jetting Pump Max Flow Rate 170 Lpm

- EA Series Sewer Jetting Pump Max Flow Rate 100 Lpm

- PressureJet ES Series Sewer Jetting Pump Max Flow Rate 412 Lpm

- HW Series - Sewer Jetting Pump

- EA Series Sewer Jetting Pump Max Flow Rate 155 LPM

- Pressure Washer

- Jet Cleaners

- Water Blasting Machine

- High Pressure Water Jet Cleaner

- HIGH PRESSURE RECIPROCATING PUMPS

- Hydro Jetting Machine

- Extra Links

- Contact Us

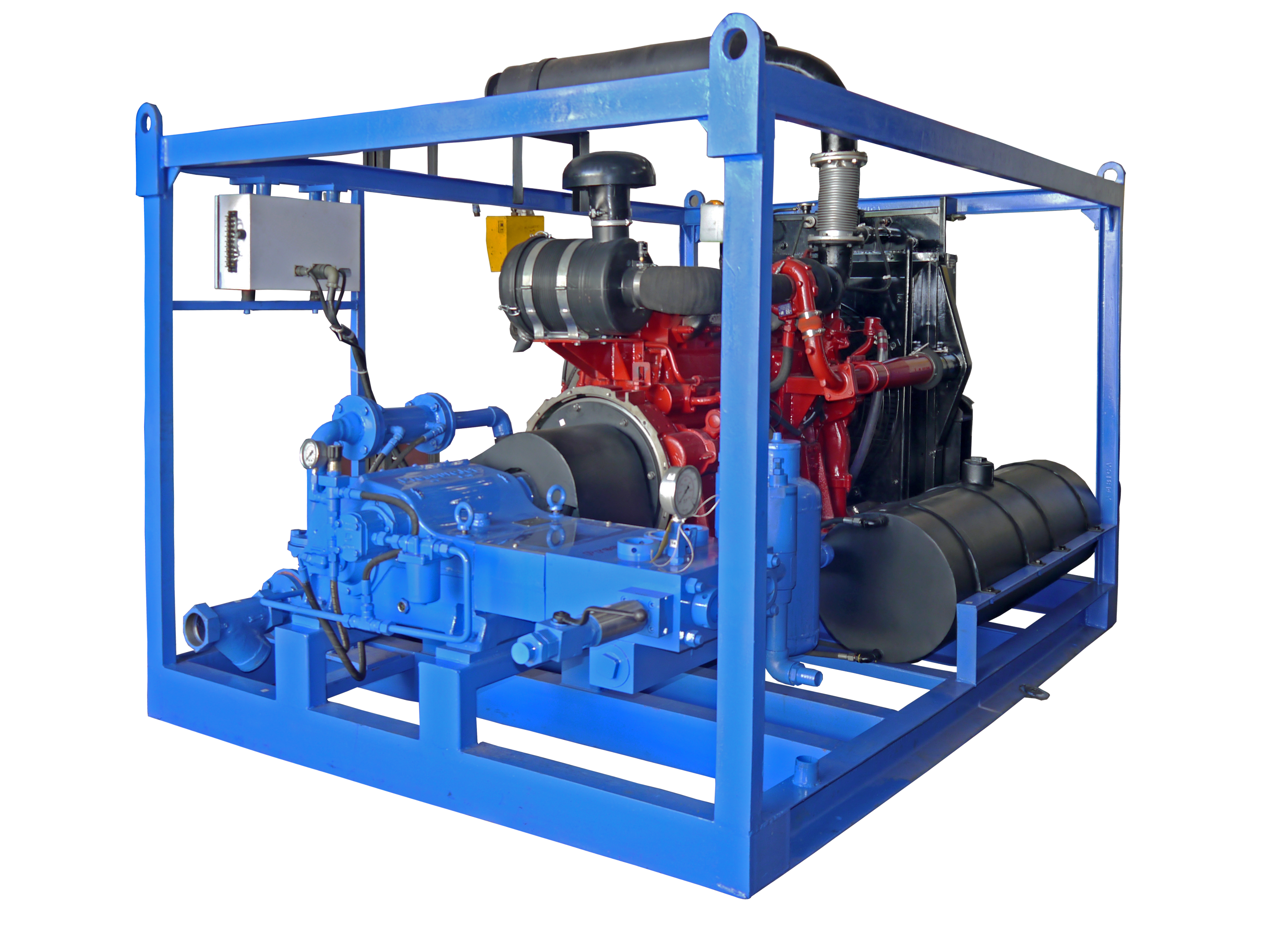

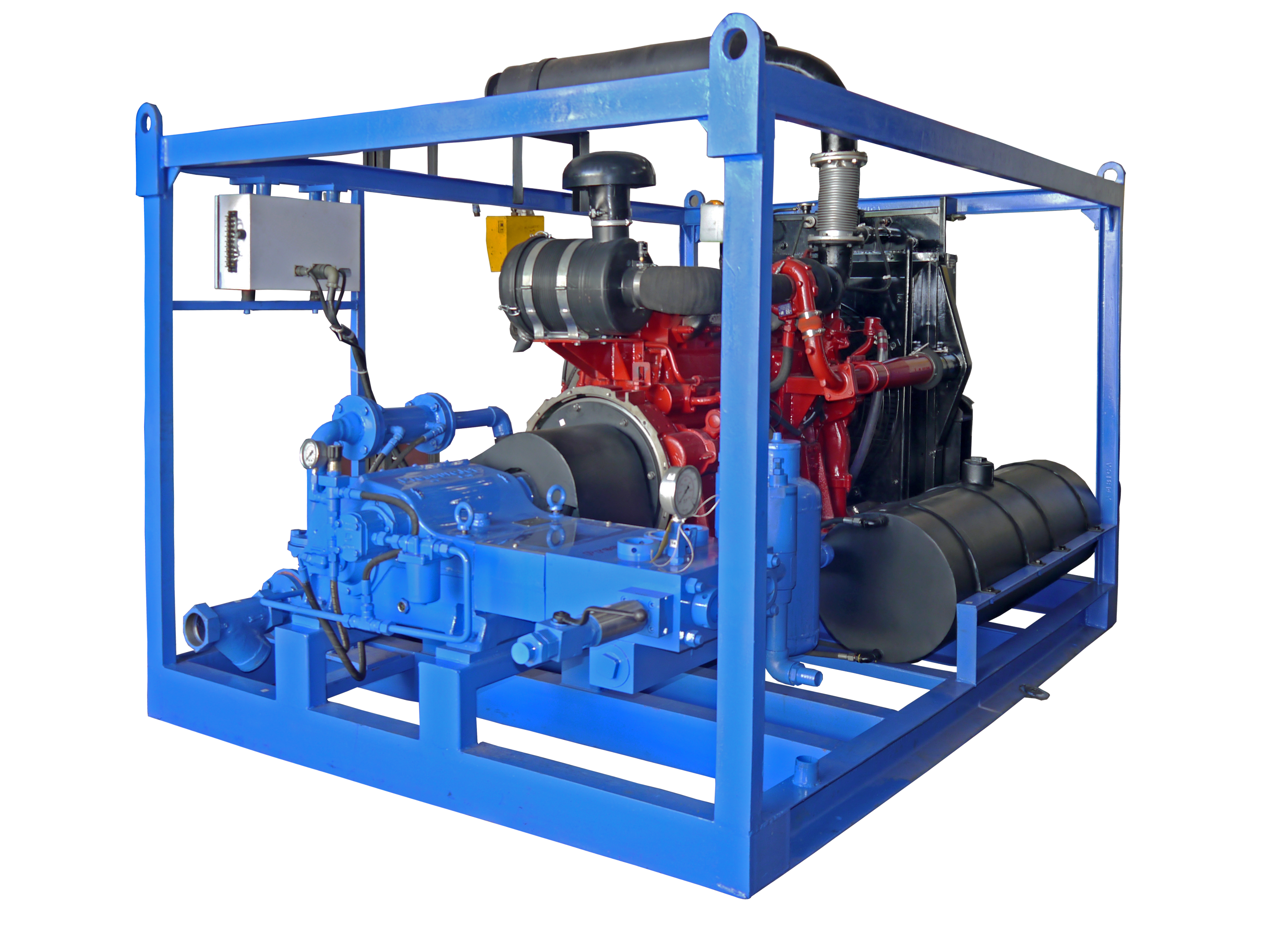

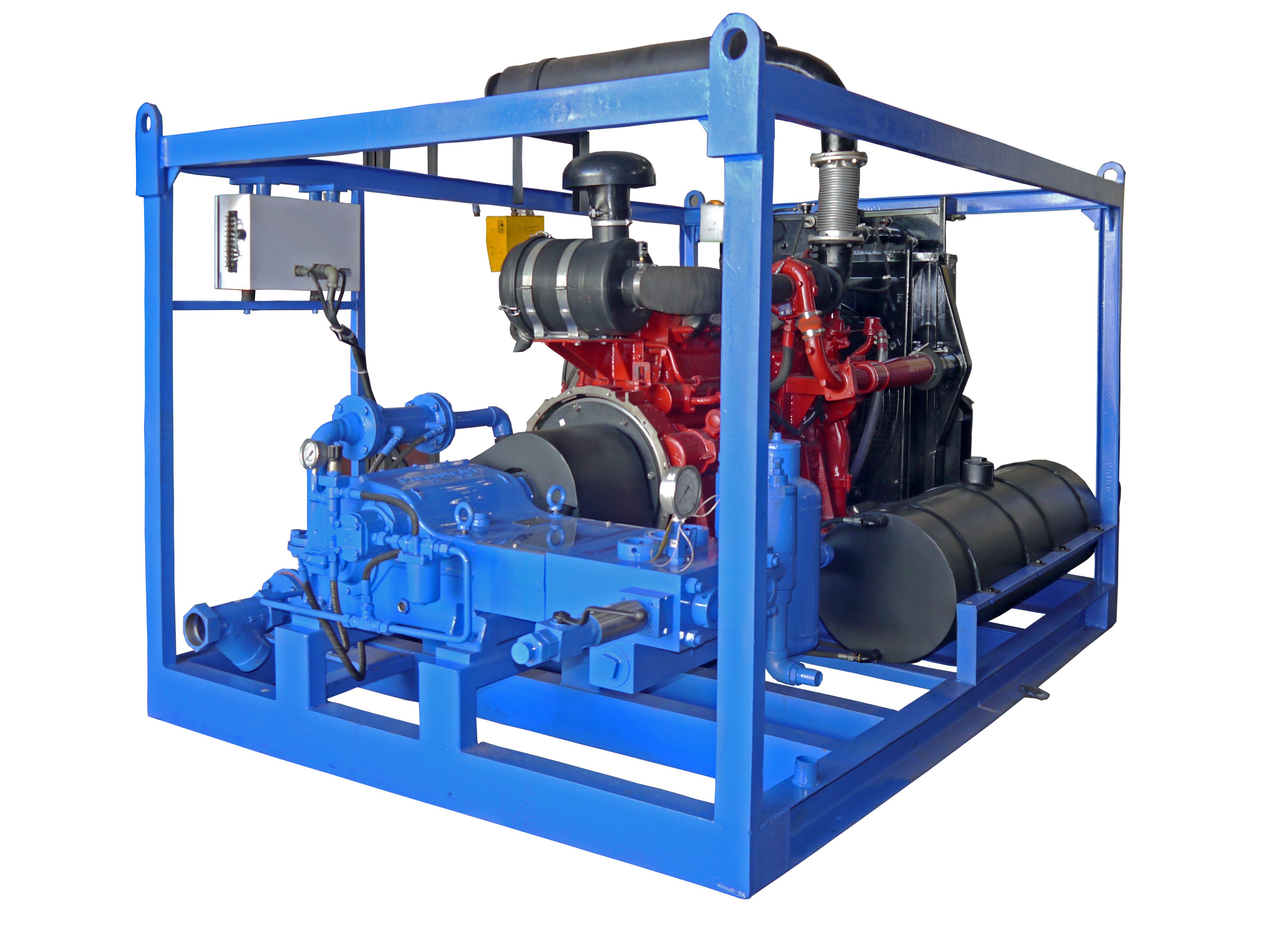

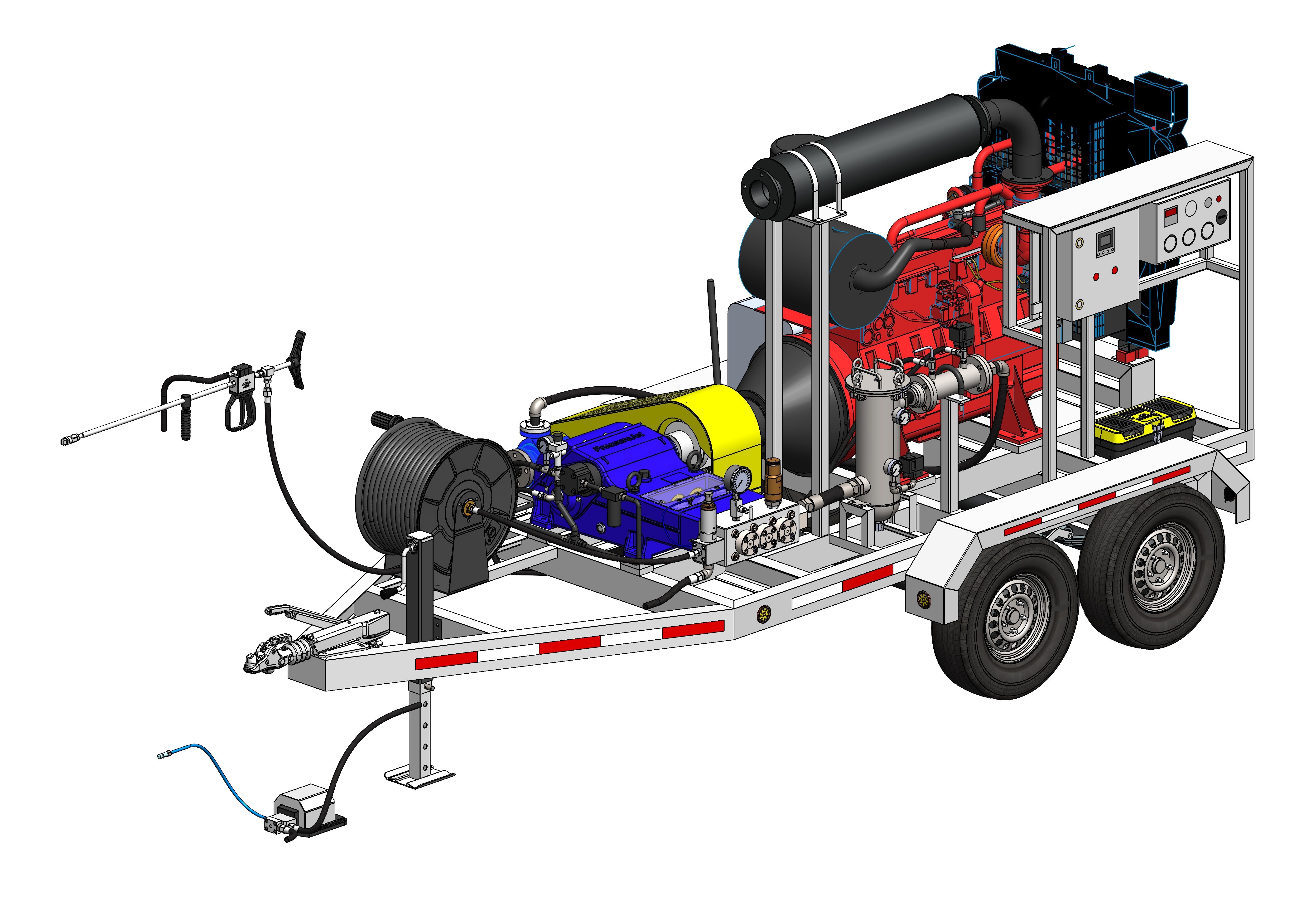

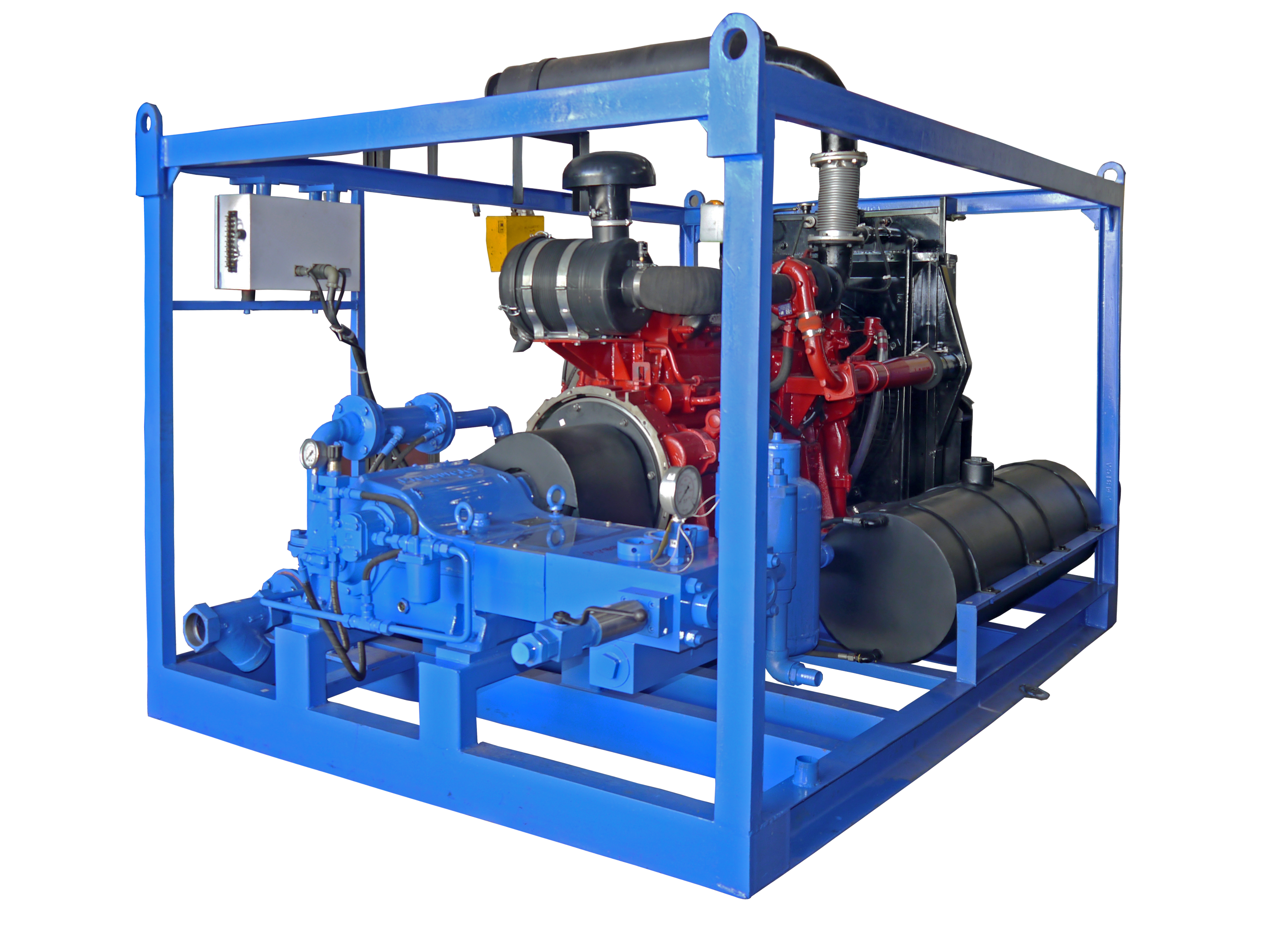

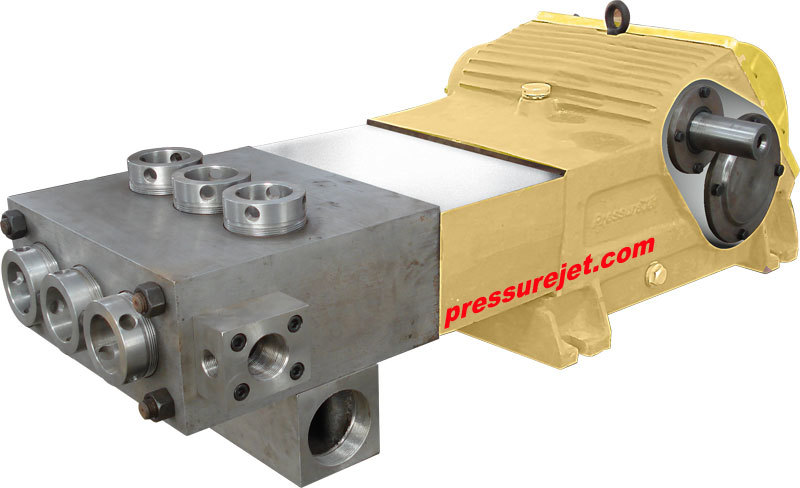

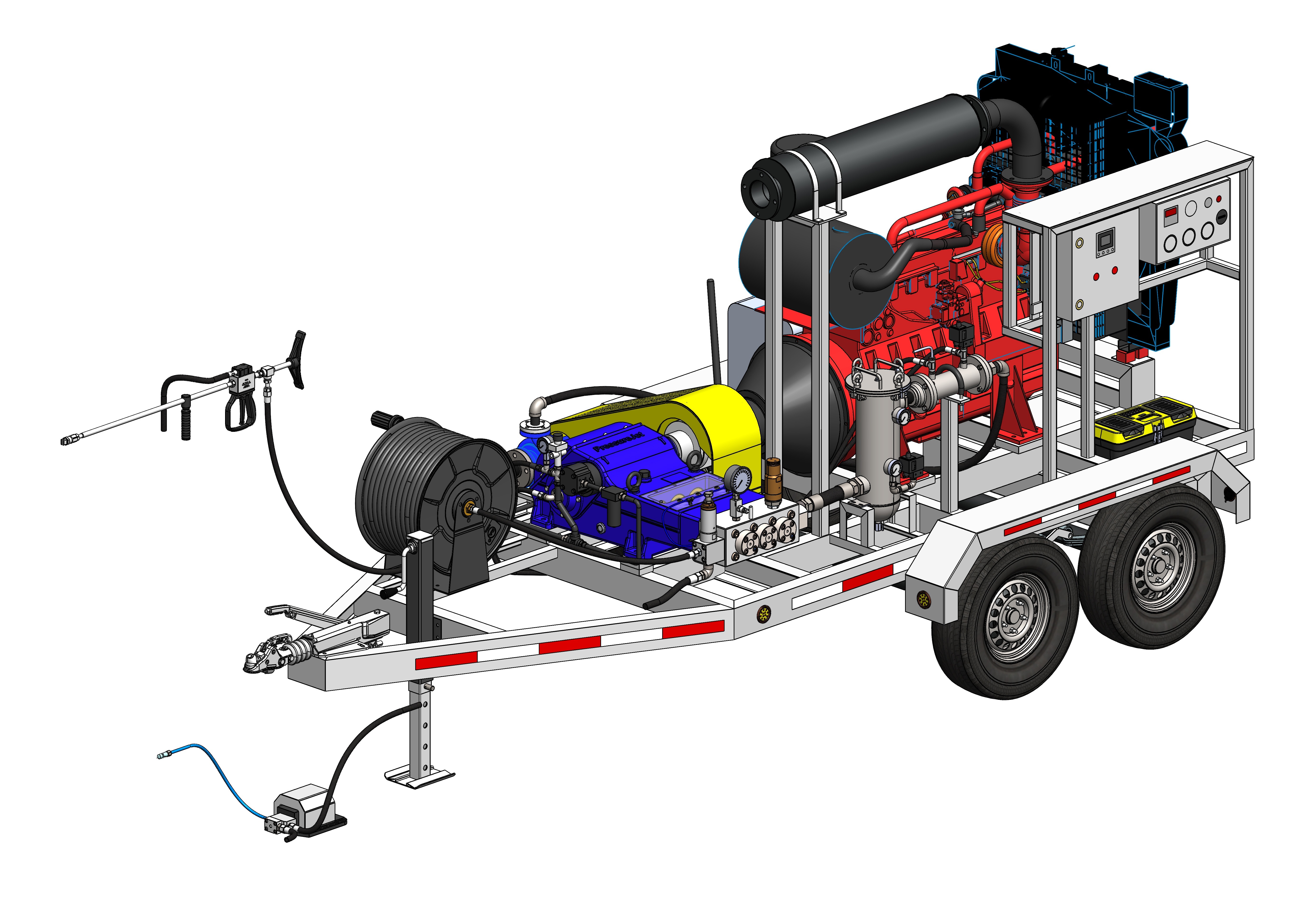

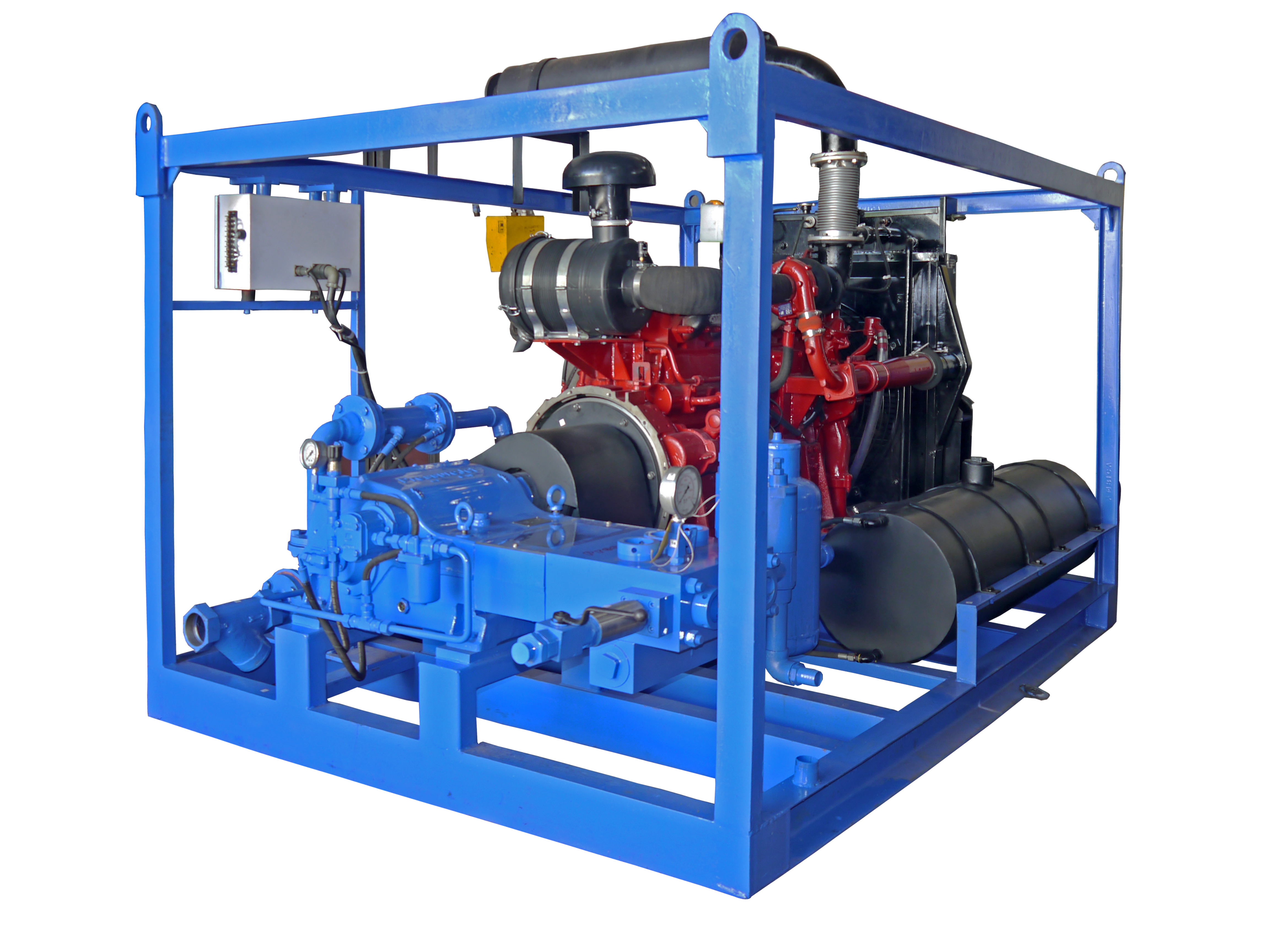

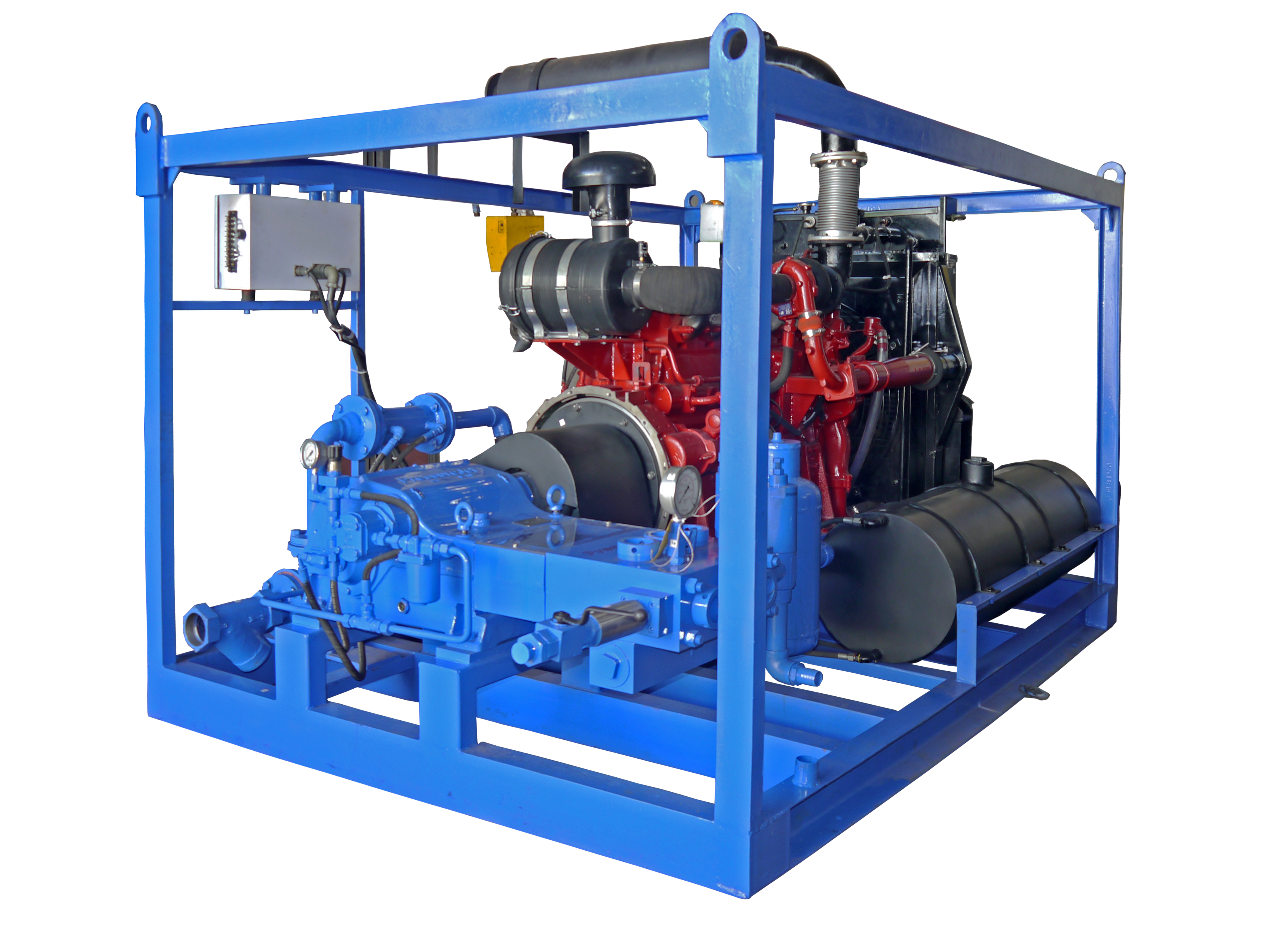

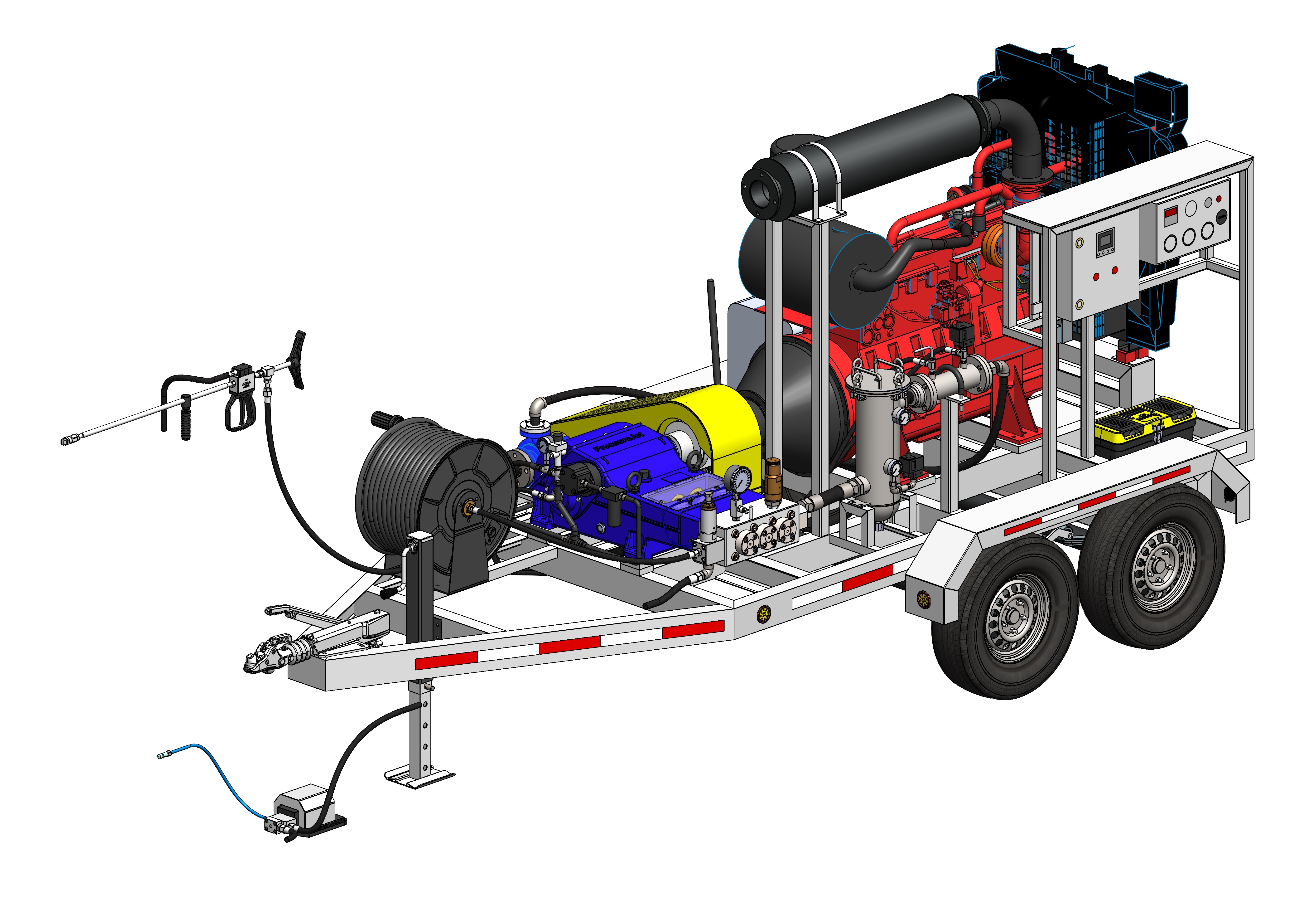

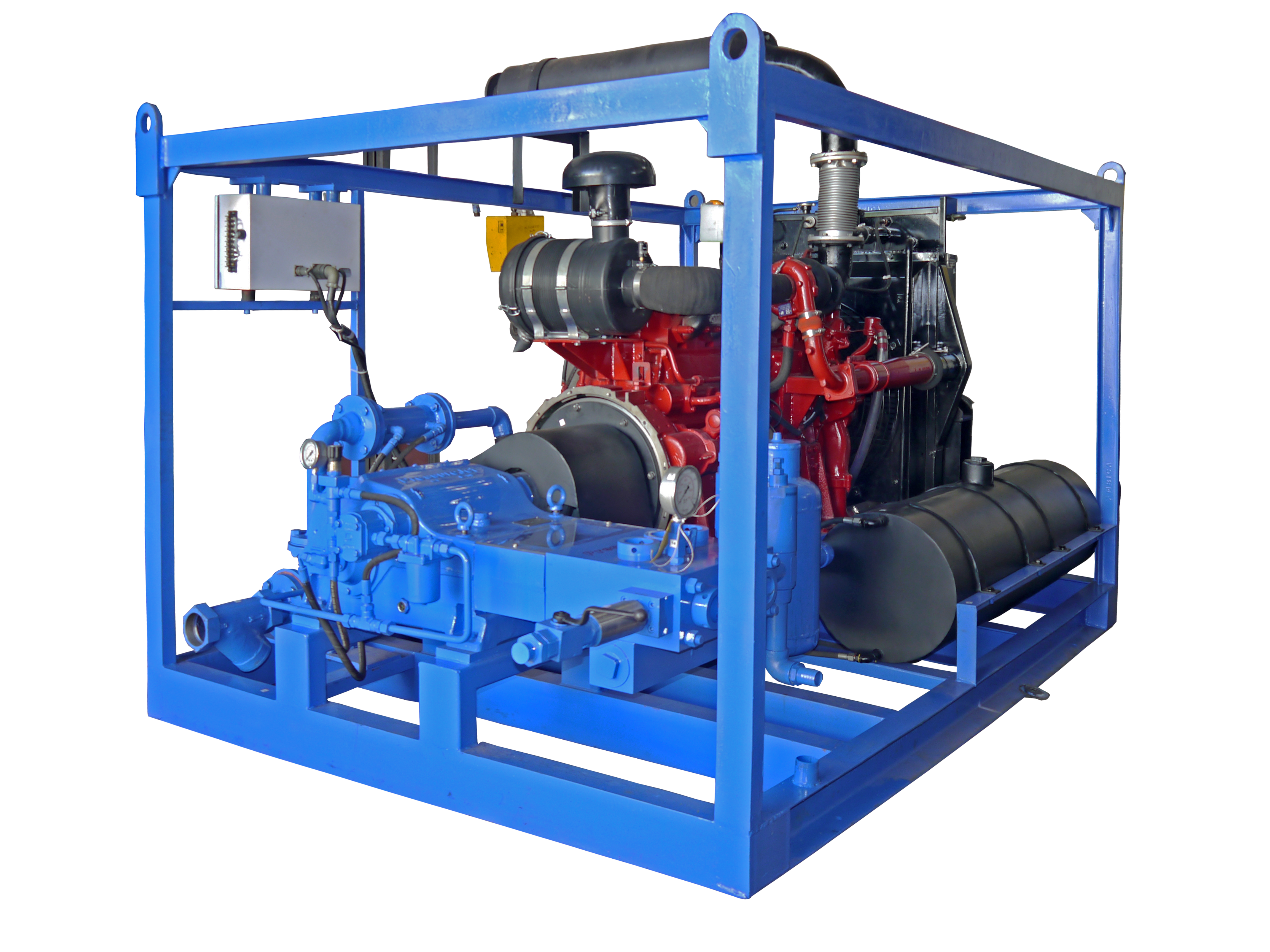

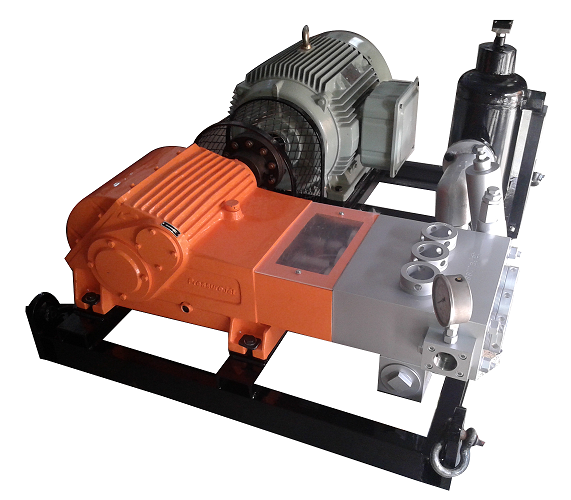

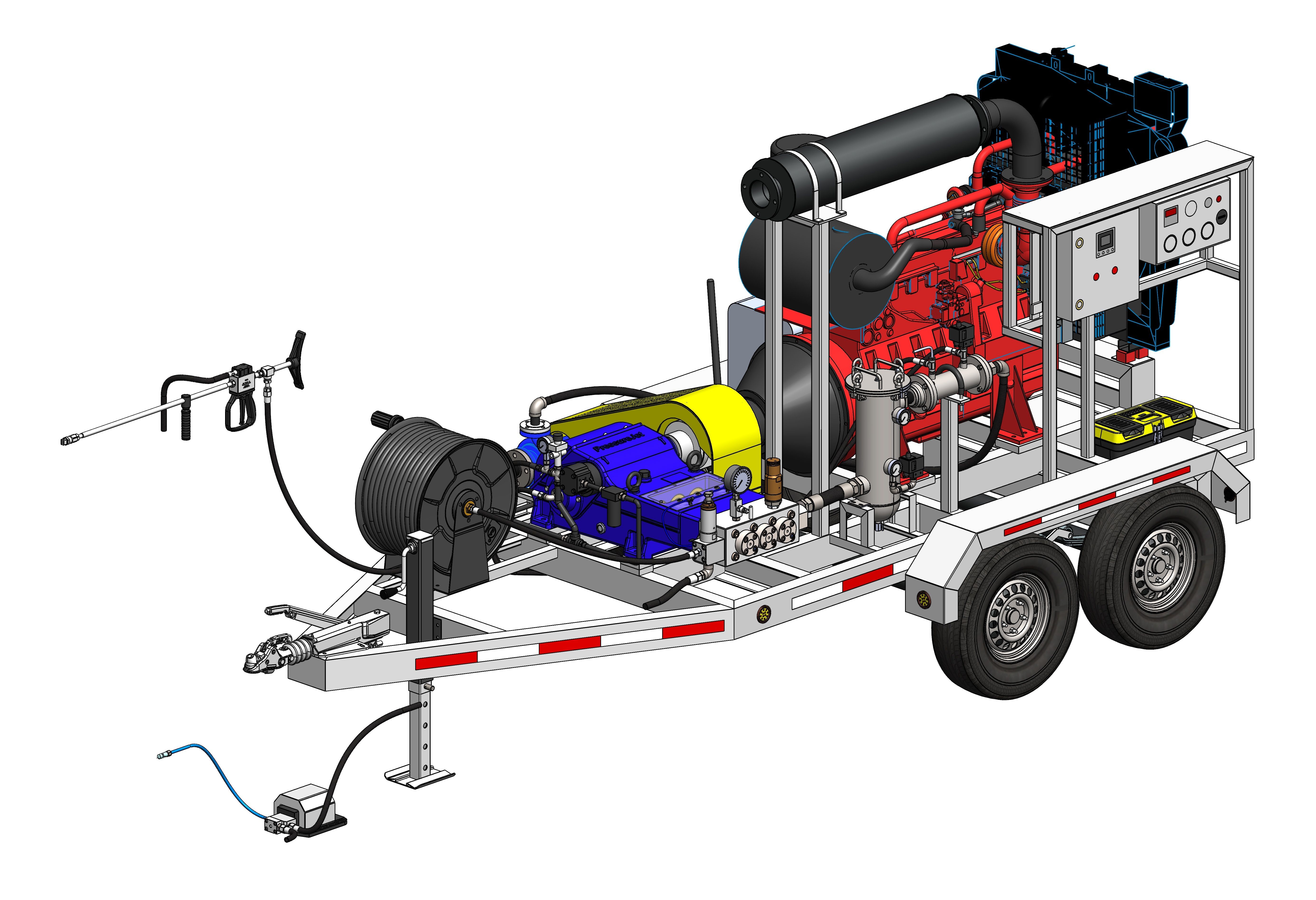

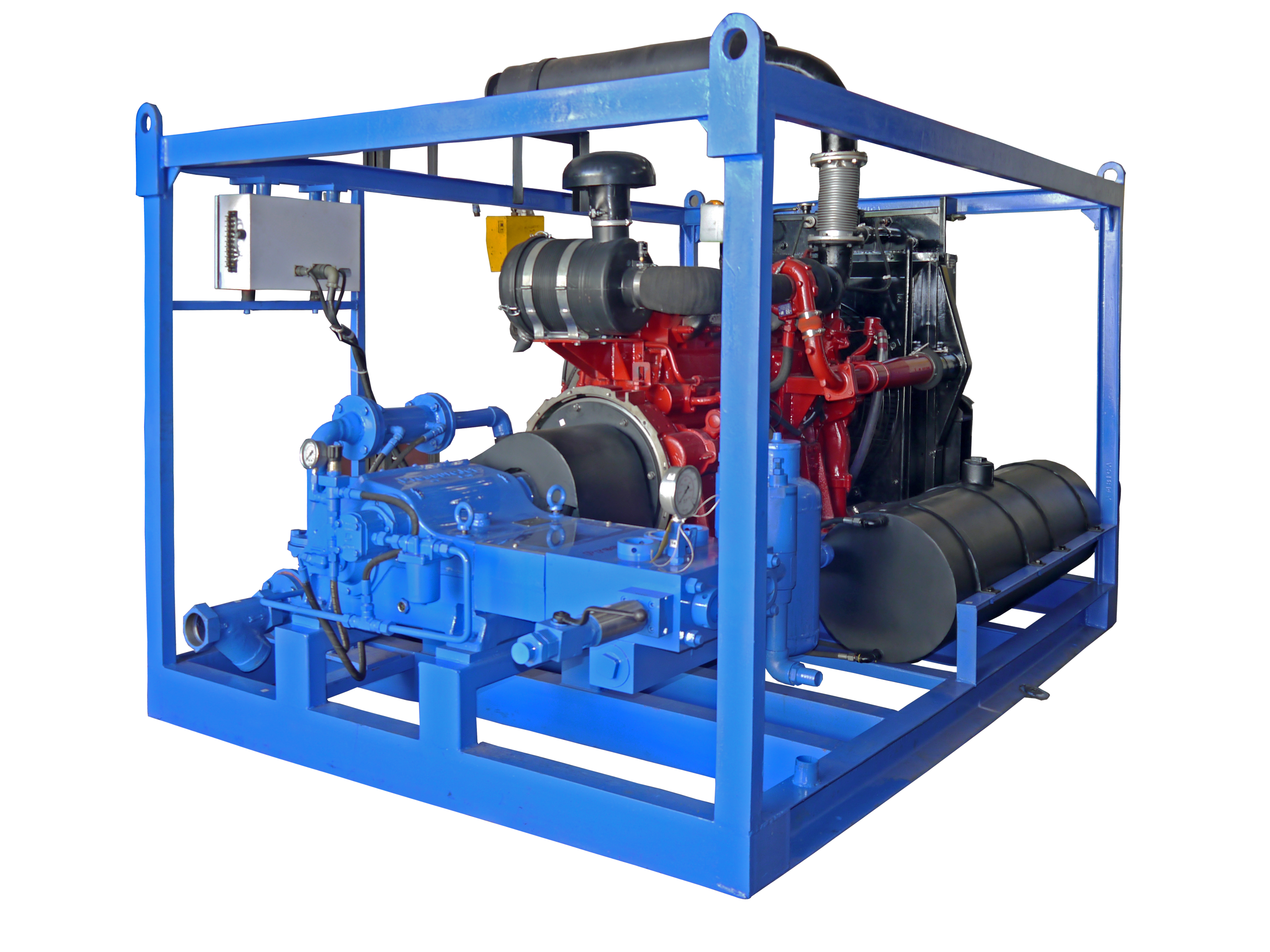

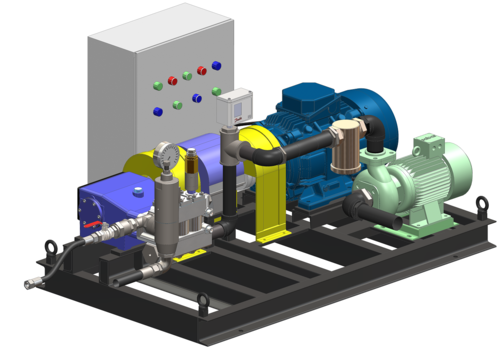

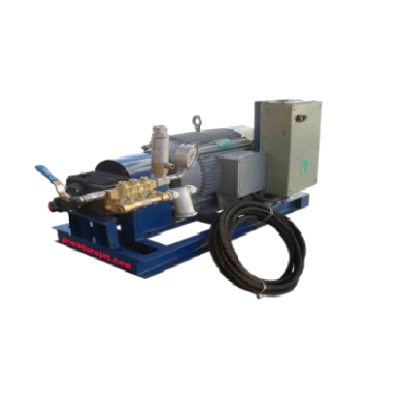

Diesel Driven Hydro Test Pump

Price 400000.00 INR/ Unit

MOQ : 1 Unit

Diesel Driven Hydro Test Pump Specification

- Theory

- Reciprocating Pump

- Flow Rate

- up to 445 lpm

- Material

- SS, Brass, SG Iron

- Size

- 110*80*72

- Structure

- Piston Pump

- Height

- 72 Inch (in)

- Fuel Type

- Diesel

- Weight

- 3000 Kilograms (kg)

- Pressure

- High Pressure

- Color

- Blue, yellow

- Length

- 110 Inch (in)

- Usage

- Other

- Width

- 80 Inch (in)

- Application

- Other

- Seals Type

- Mechanical

Diesel Driven Hydro Test Pump Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Nhava Sheva ( Mumbai ) , Pipavav , Kandla

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 2-3 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box Type Packing

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Middle East, Central America, Africa, South America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Diesel Driven Hydro Test Pump

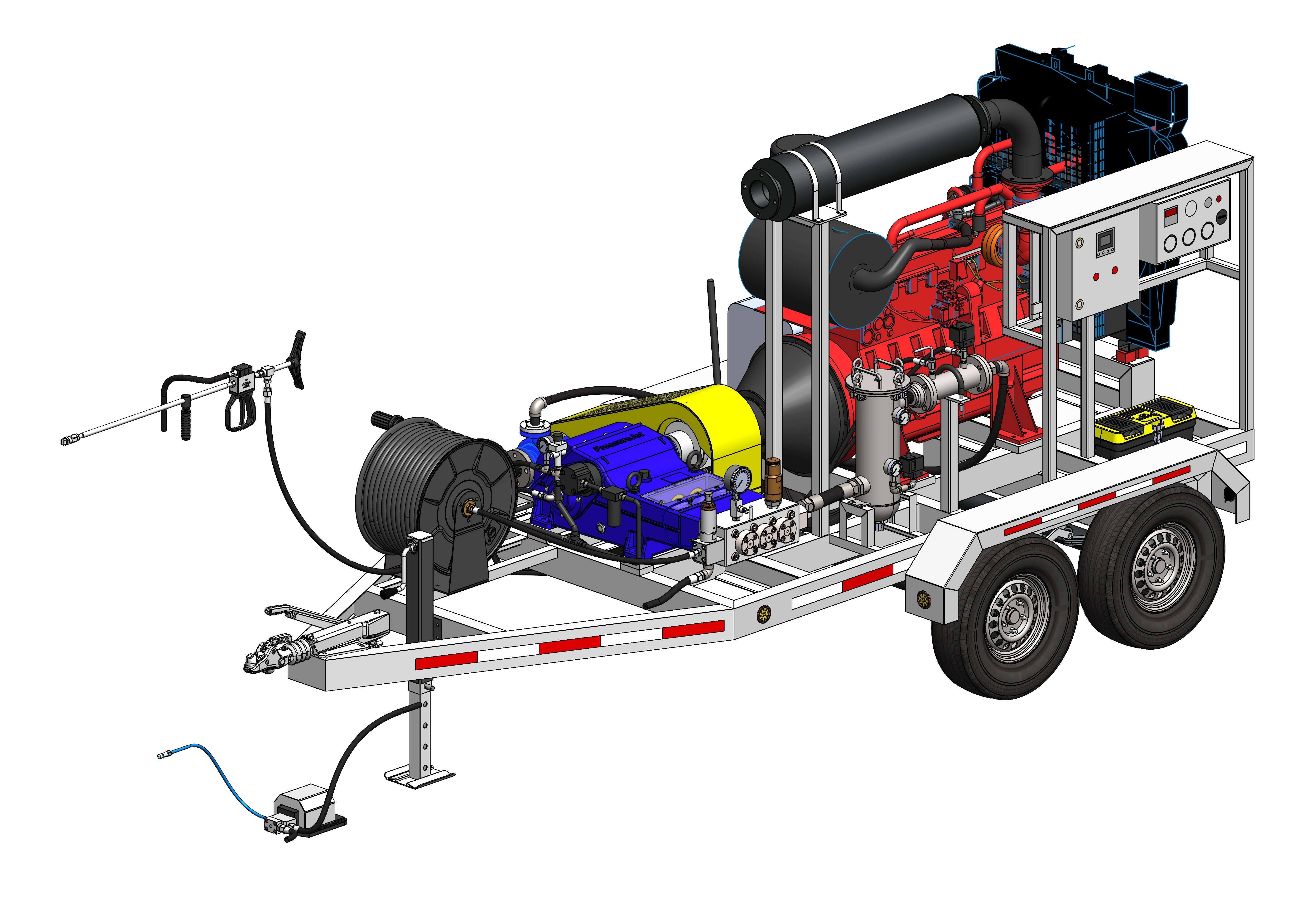

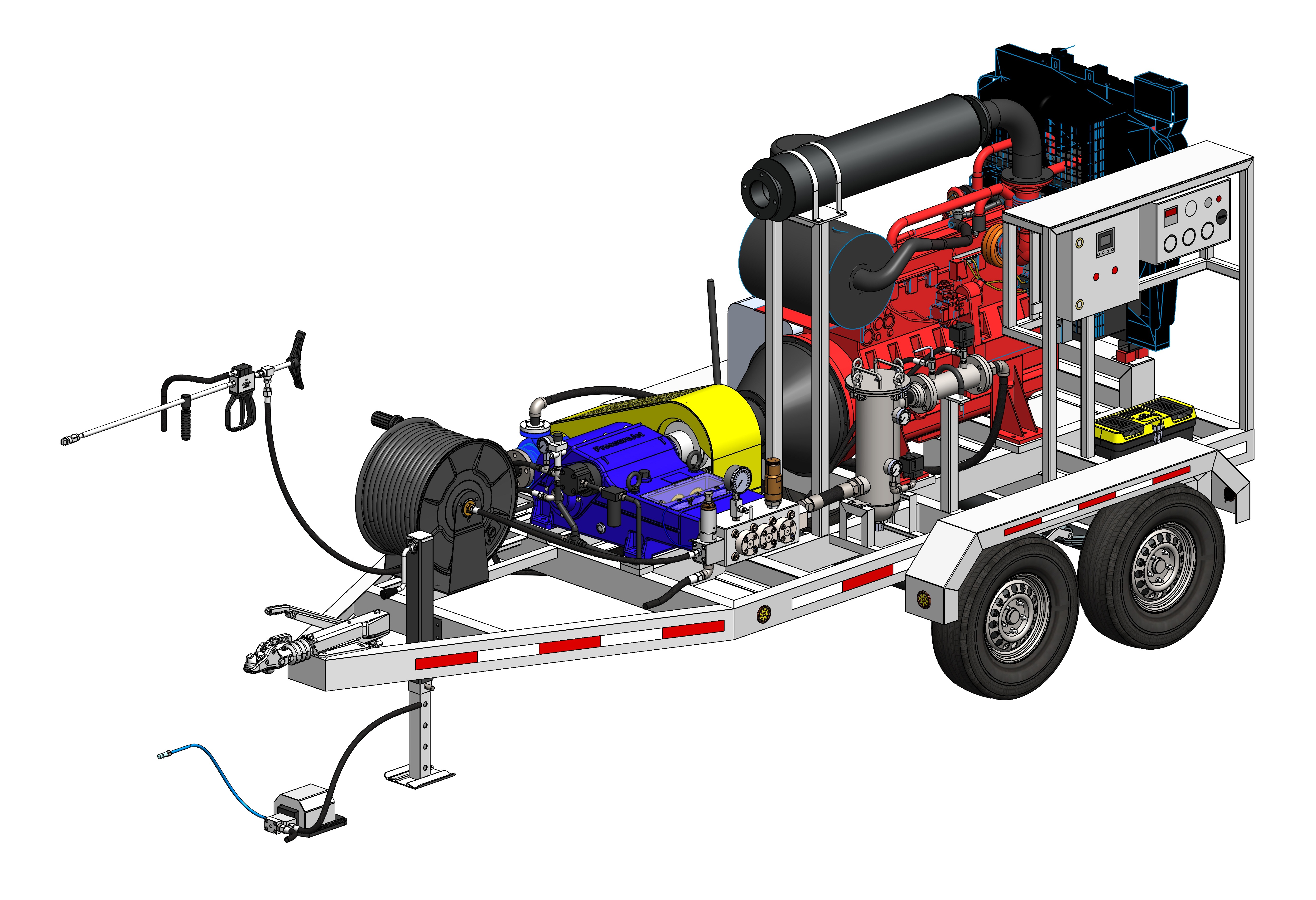

Diesel Driven Hydro Test Pump is a hydrostatic testing pump, useful for the pre-filling as well as pre-pressurizing tasks. This is the most preferred solution, appreciable for its compact design, cost effective operation etc. The pump has diverse combinations of flow & pressure. It has a highly functional controller, which is its standard feature. Diesel Driven Hydro Test Pump is provided with improved operational efficiency and can do away with many operator mistakes. It boasts of an optimum diagnostic technique that allows it to perform various types of hydrostatic tests. The safety relief controls it has ensures the secured operation.

Product Details:

|

Minimum Order Quantity |

1 Unit |

|

Condition |

New |

|

Brand |

PressureJet |

|

Driven Type |

Electric motor driven, Diesel engine driven |

|

Rpm |

For 50 Hz - 1450 RPM |

|

Product Tags |

High Pressure Hydro Testing Pumps, Electric motor Driven Hydro Testing Pump, Hydro Testing Pump |

|

Product Name Tags |

Hydrostatic Pressure Testing Pump, Diesel Engine Driven Hydro Testing Pump |

|

Pressure Range |

150 bar to 200 bar |

|

Power Supply |

Available in 50 Hz and 60 Hz |

|

Portable |

Yes |

|

Mounting Option |

Trolly Mounted, Skid Mounted |

|

Material Available |

SS, Brass, SG Iron |

|

Flow Rate |

300 LPM to 445 LPM |

Exceptional Performance for Industrial Hydro Testing

The Diesel Driven Hydro Test Pump stands out for its ability to generate high pressure, making it perfect for demanding applications such as cross country pipe line testing, steam coil, and cylinder hydro tests. Its piston-based reciprocating mechanism ensures precision and sturdiness, even in tough operating conditions.

Reliable Engineering and Construction

Crafted from premium materials including stainless steel, brass, and SG iron, this pump offers superior durability and corrosion resistance. Its mechanical seal type and robust construction minimize maintenance needs, ensuring long operational life and consistent performance.

Wide Range of Use Cases

From pipeline integrity verification to on-site hydrostatic testing, this pump serves diverse industrial needs. Its compatibility with diesel fuel adds to its portability and suitability for remote locations. The flexible design supports different industry requirements, ensuring reliable results every time.

FAQ's of Diesel Driven Hydro Test Pump:

Q: How does the diesel driven hydro test pump operate during testing processes?

A: The pump uses a reciprocating piston mechanism, powered by a diesel engine, to generate high pressure and deliver water at rates up to 445 lpm. This high-pressure water is used for hydrostatic testing of pipelines, cylinders, and other equipment to check for leaks or structural integrity.Q: What are the primary applications for this hydro test pump?

A: This pump is widely used for cross country pipe line testing, steam coil hydro tests, and cylinder hydro tests. Its adaptability also makes it suitable for various high-pressure industrial testing operations requiring accurate and reliable results.Q: When is it appropriate to use a diesel driven hydro test pump instead of an electric model?

A: A diesel model is recommended in locations lacking reliable electricity or for fieldwork in remote areas. The diesel engine provides greater portability and ensures uninterrupted operation during intensive on-site testing tasks.Q: Where can this hydro test pump be deployed effectively?

A: This pump is effective in industrial sites such as pipeline installations, manufacturing plants, power stations, and field locations across India. Its portability and sturdy build make it suitable for both controlled environments and rugged outdoor use.Q: What is the process for setting up the hydro test pump?

A: To set up, position the pump on a stable surface, connect the water inlet and outlet hoses, fill the water tank, and ensure all fittings are secure. Start the diesel engine and gradually increase the pressure as required for the specific test. Always follow safety and operational guidelines provided by the manufacturer.Q: Why should distributors and service providers consider this pump?

A: Distributors and service providers benefit from the pump's robust design, high testing capacity, and minimal maintenance requirements. Its versatility and reliable performance enhance service offerings for a broad range of industrial clients in competitive markets.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Hydro Test Pump Category

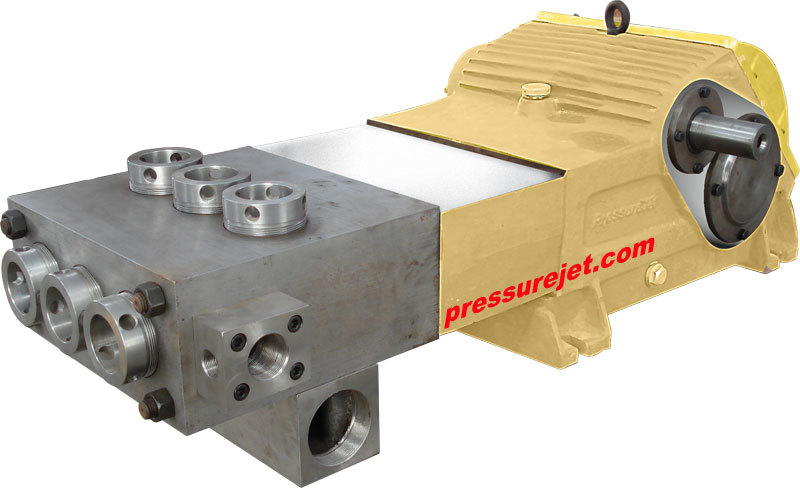

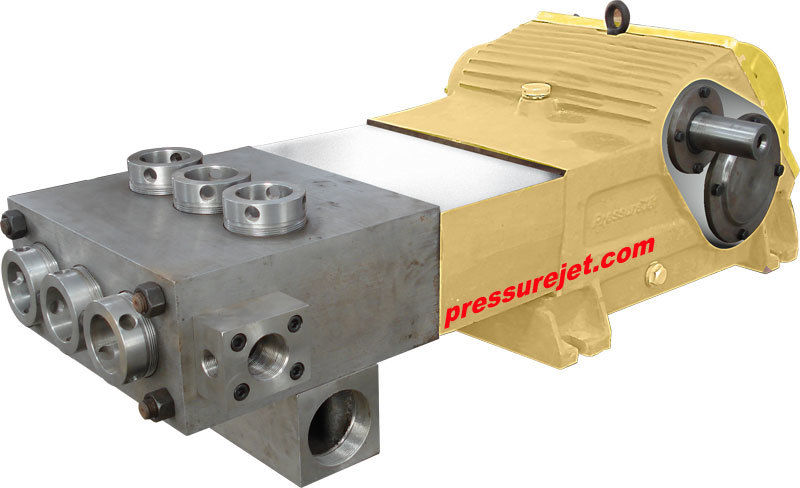

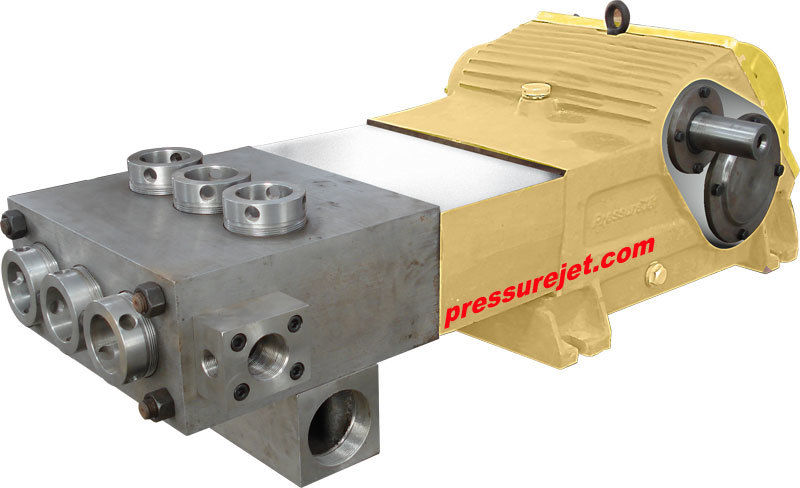

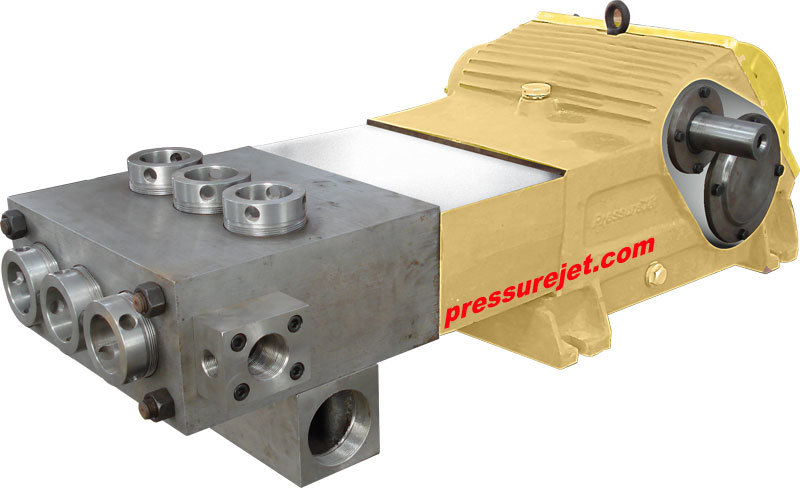

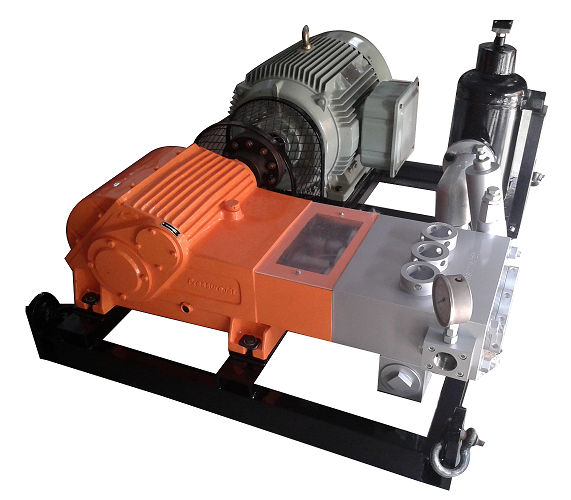

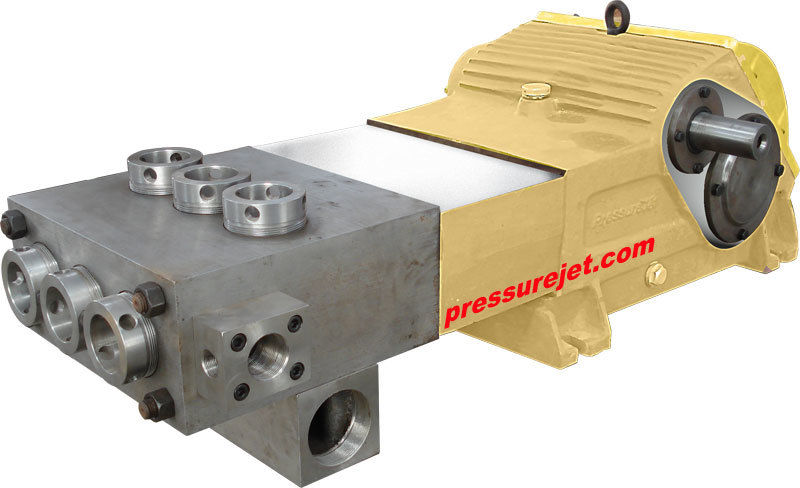

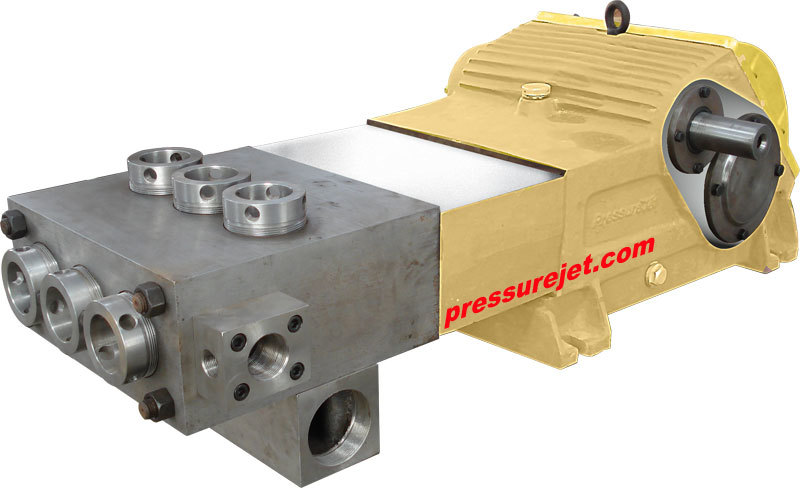

Triplex Plunger Hydro Test Pump

Price 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Theory : Reciprocating Pump

Usage : Water, Automobile, Other

Height : 198 Millimeter (mm)

Seals Type : Mechanical

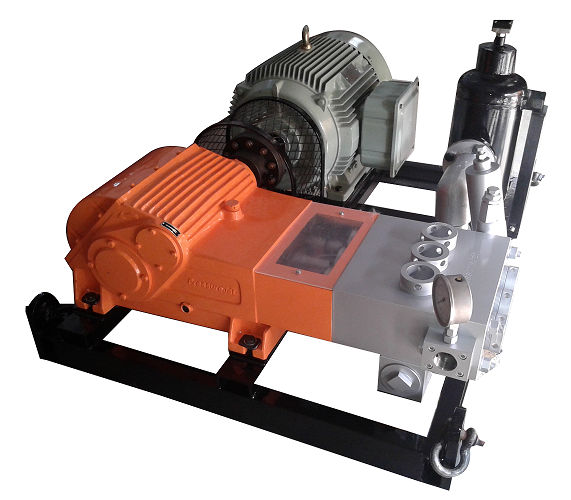

Stainless Steel Hydro Test Pump

Price 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Theory : Reciprocating Pump

Usage : Water, Automobile, Other

Height : 24 Inch (in)

Seals Type : Durable Fiber Impregnated Bunan Seal

PressureJet Brass, S.s High Pressure Hydrotest Pump (Hydrostatic Test ) , Max Flow Rate: 197

Price 100000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Theory : Reciprocating Pump

Usage : Water, Other

Height : 360 Millimeter (mm)

Seals Type : Special Teflon base high pressure seal

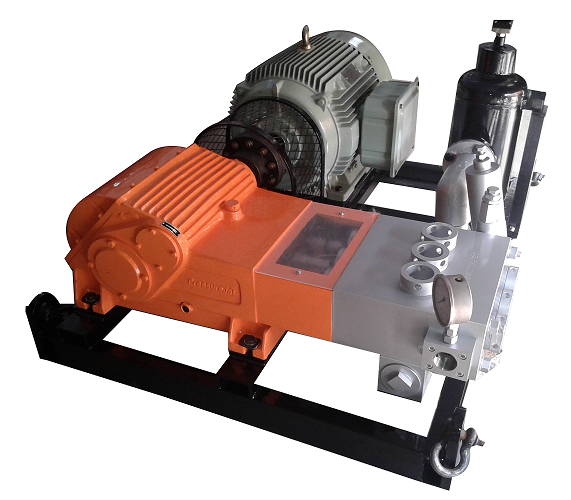

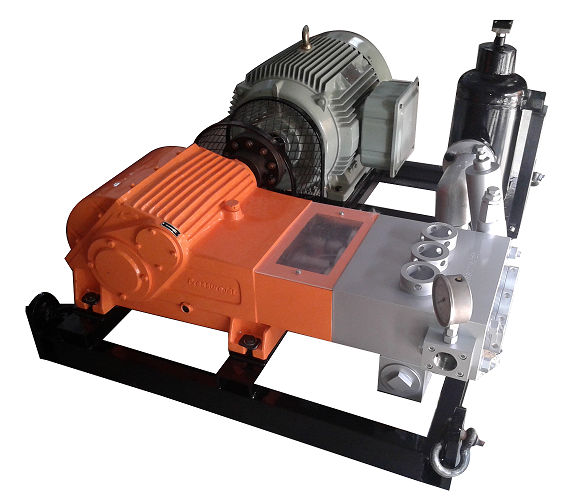

Motorized Hydro Test Pump

Price 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Theory : Reciprocating Pump

Usage : Water, Automobile, Other

Height : 27 Inch (in)

Seals Type : Mechanical

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS