- Home Page

- Company Profile

-

Our Products

- Hydro Jetting Machine

- 1000 Bar 10000 PSI Electric Pressure Washer

- PressureJet Hydro Jetting Pump

- Hydro Jetting System

- Hydro Jetting Machine PressureJet

- PressureJet Hydro Jet Cleaning Machine

- Hydro Jetting Machines

- 20000 PSI Hydro Jetting Machine

- High Pressure Hydro Jetting Equipment

- High Pressure Hydro Jetting Machine

- Hydro Jetting Machine

- Hydro Jetting Equipment

- Hydro Blasting Machine

- 20K Hydroblaster Semi-Automatic Hydroblaster 20 K

- Pressure Jet Hydro Blasting Equipment

- 10000 PSI Hydro Blaster Semi-Automatic Hydro Blaster 10000 PSI

- 10K Water Blaster Semi-Automatic Water Blaster 10 K

- High Pressure Hydro Blasting System

- Pressure Jet Semi-Automatic Hydro Blasting Equipment

- Pressure Jet 3 Phase High Pressure Water Blaster

- 3 Phase Pumps 20000 PSI Pressure Washer

- Water Jet Cleaner

- Hydro Test Pump

- PressureJet Brass, S.s High Pressure Hydrotest Pump (Hydrostatic Test ) , Max Flow Rate: 197

- Stainless Steel Hydro Test Pump

- High Pressure Hydro Test Pump

- Motorized Hydro Test Pump

- Triplex Plunger Hydro Test Pump

- High Pressure Hydrostatic Test Pump

- Hydrostatic Pressure Testing Pump

- Diesel Driven Hydro Test Pump

- High Pressure Hydro Test Pump Unit

- Triplex Plunger Pumps

- Sewer Jetting Pump

- PressureJet EM Series Sewer Jetting Pump Max Flow Rate 267 Lpm

- VA Series Sewer Jetting Pump Max Flow Rate 170 Lpm

- EA Series Sewer Jetting Pump Max Flow Rate 100 Lpm

- PressureJet ES Series Sewer Jetting Pump Max Flow Rate 412 Lpm

- HW Series - Sewer Jetting Pump

- EA Series Sewer Jetting Pump Max Flow Rate 155 LPM

- Pressure Washer

- Jet Cleaners

- Water Blasting Machine

- High Pressure Water Jet Cleaner

- HIGH PRESSURE RECIPROCATING PUMPS

- Hydro Jetting Machine

- Extra Links

- Contact Us

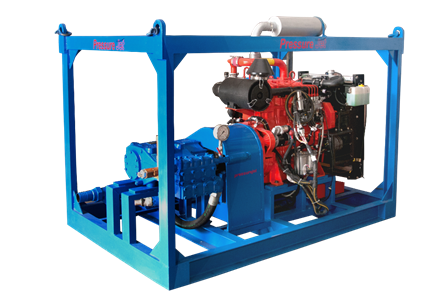

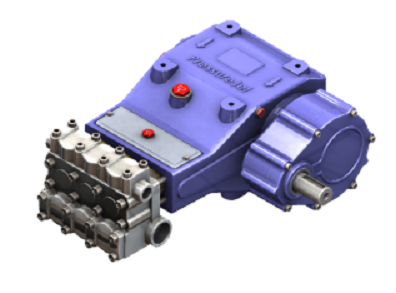

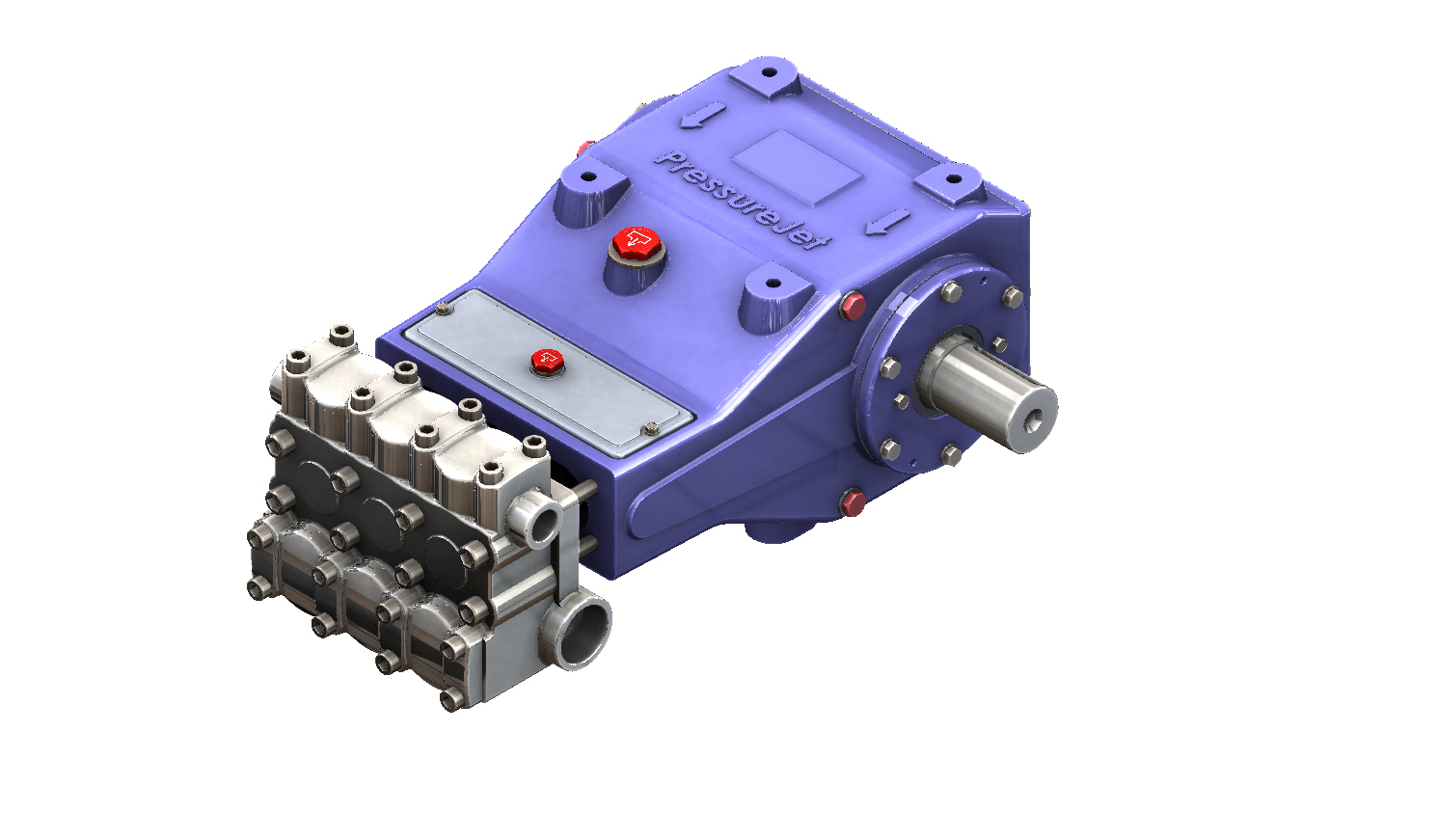

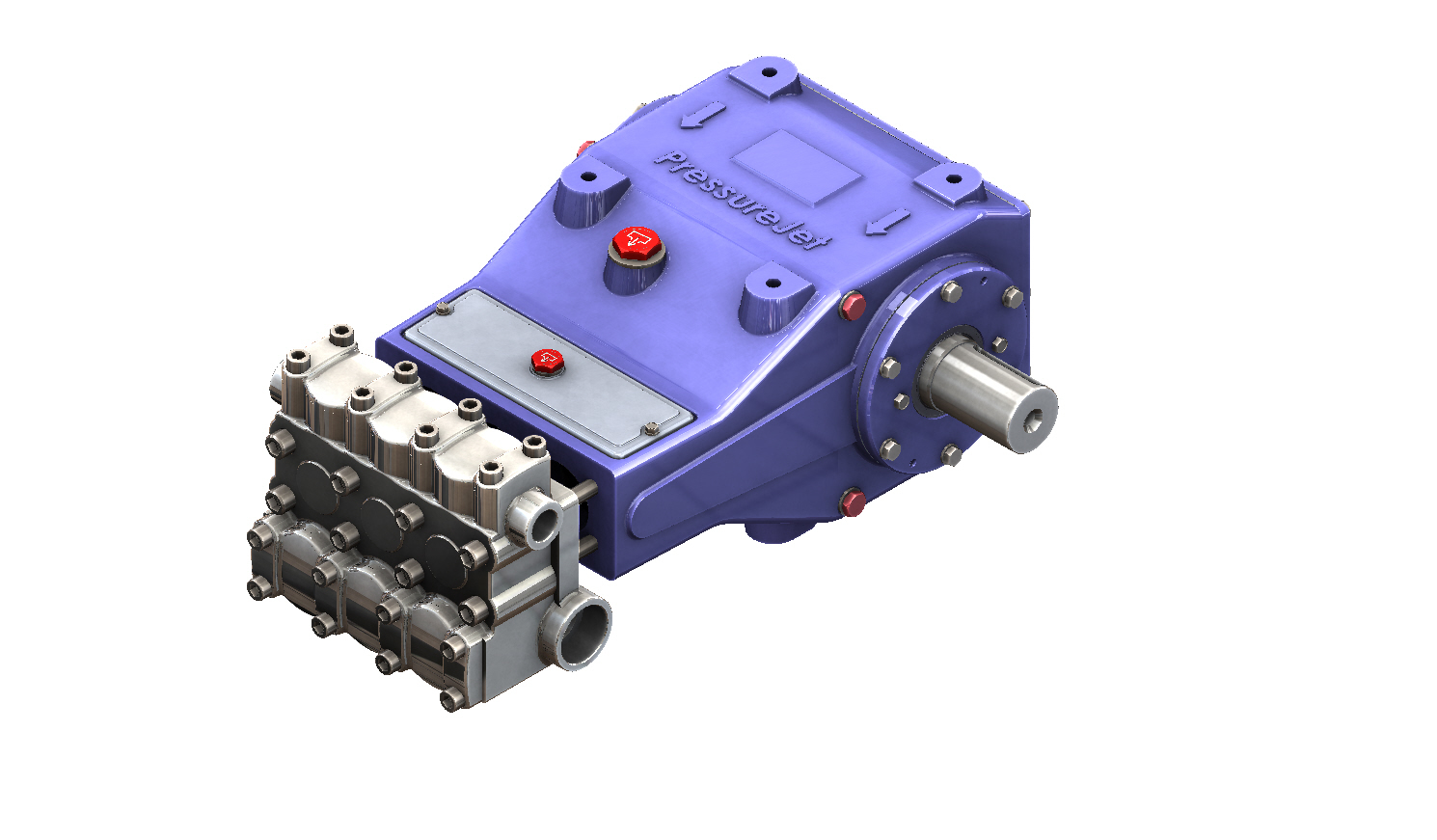

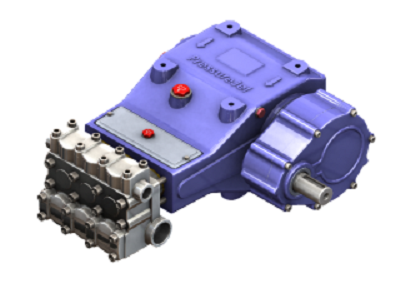

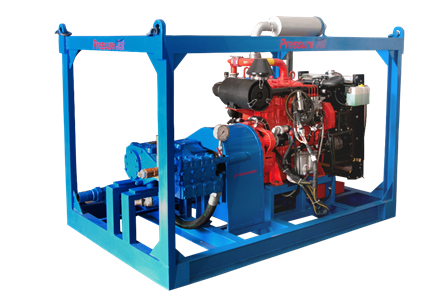

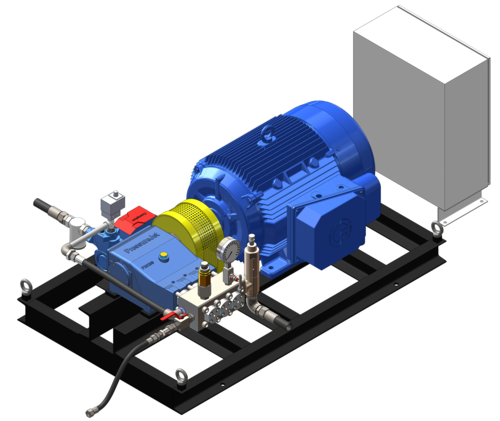

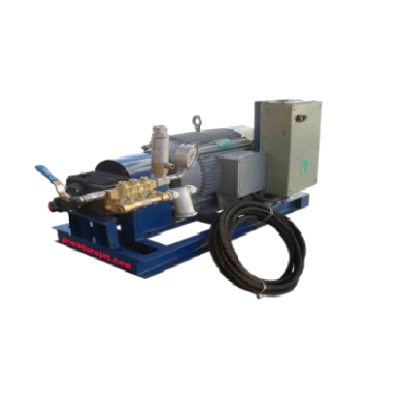

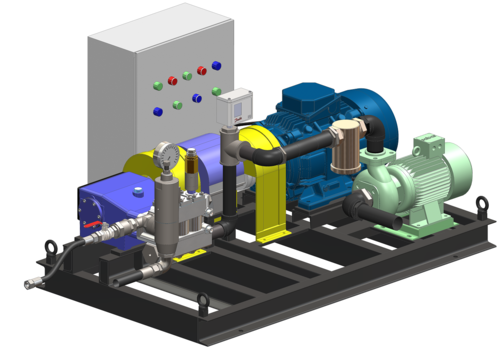

PressureJet Brass, S.s High Pressure Hydrotest Pump (Hydrostatic Test ) , Max Flow Rate: 197

Price 100000.00 INR/ Unit

MOQ : 1 Unit

PressureJet Brass, S.s High Pressure Hydrotest Pump (Hydrostatic Test ) , Max Flow Rate: 197 Specification

- Inlet/Outlet

- BSPF

- Theory

- Reciprocating Pump

- Flow Rate

- 197

- Material

- SS,Brass,SG Iron

- Structure

- Piston Pump

- Size

- 1192*592*360

- Power

- Electric

- Height

- 360 Millimeter (mm)

- Weight

- Approx weight of bare pump: 430 Kilograms (kg)

- Color

- Blue

- Pressure

- High Pressure

- Usage

- Water

- Length

- 1192 Millimeter (mm)

- Width

- 592 Millimeter (mm)

- Application

- Other

- Seals Type

- Special Teflon base high pressure seal

PressureJet Brass, S.s High Pressure Hydrotest Pump (Hydrostatic Test ) , Max Flow Rate: 197 Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Nhava Sheva ( Mumbai ) , Pipavav , Kandla

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 2 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing Box Type

- Main Export Market(s)

- Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About PressureJet Brass, S.s High Pressure Hydrotest Pump (Hydrostatic Test ) , Max Flow Rate: 197

Product Details:

|

Material Available |

SS,Brass,SG Iron |

|

Brand |

PressureJet |

|

Flow Rate |

197 LPM |

|

Mounting Option |

Trolly Mounted,Skid Mounted |

|

Rpm |

For 50 Hz - 1450 RPM |

|

Product Tags |

High Pressure Hydro Testing Pumps,Electric motor Driven Hydro Testing Pump,Hydro Testing Pump |

|

Product Name Tags |

Hydrostatic Pressure Testing Pump,Diesel Engine Driven Hydro Testing Pump |

|

Pressure Range |

295 bar |

|

Power Supply |

Available in 50 Hz and 60 Hz |

Versatile Testing for Industrial Applications

Designed for rigorous hydrostatic testing, this high-pressure pump handles water testing for a diverse range of equipment, including pipelines, steam coils, and gas cylinders. Its adaptability across various sectors makes it a valuable tool for manufacturers, service providers, and testing facilities seeking reliable pressure assessment.

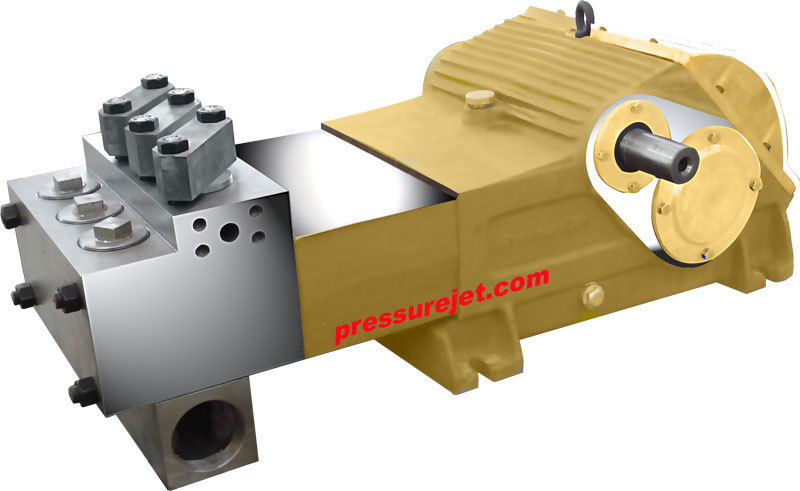

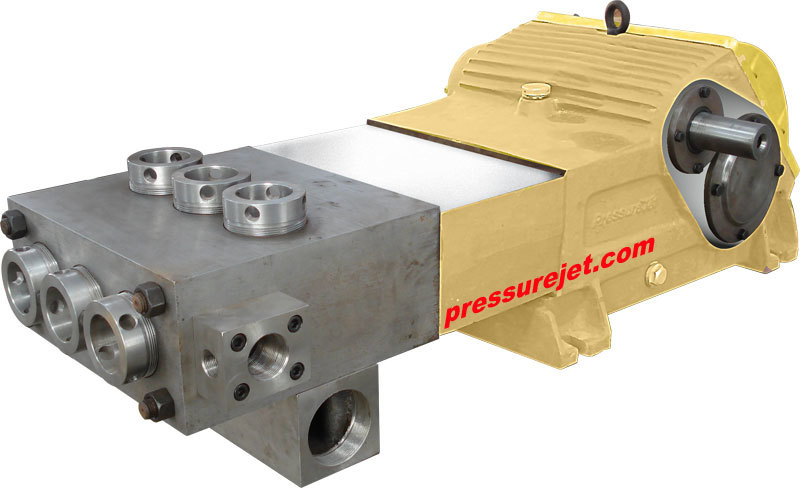

Superior Design and Reliable Performance

Constructed from stainless steel, brass, and SG iron, the pump combines durability with longevity. The reciprocating piston mechanism ensures consistent high-pressure output, while special Teflon-based seals provide robust sealing performance. Its compact structure and effective design support easy installation and maintenance.

FAQ's of PressureJet Brass, S.s High Pressure Hydrotest Pump (Hydrostatic Test ) , Max Flow Rate: 197:

Q: How does the PressureJet High Pressure Hydrotest Pump operate during a hydrostatic test?

A: This pump uses a reciprocating piston mechanism to pressurize water, forcing it through the equipment under test. Its electric motor powers the piston, enabling controlled, high-pressure water flow for precise hydrostatic testing, ensuring leak detection and strength verification.Q: What materials are used in the construction of the Hydrotest Pump, and why are they beneficial?

A: The pump is manufactured from stainless steel, brass, and SG iron. These materials offer excellent corrosion resistance, durability, and strength under high pressure, making the pump suitable for demanding hydrostatic testing applications.Q: When should I use this hydrotest pump for equipment testing?

A: Use this pump whenever you need to verify the integrity or strength of pressure vessels, cross-country pipelines, steam coils, or cylinders. It is ideal for pre-commissioning, routine inspections, and maintenance checks to ensure equipment safety.Q: Where can this pump be deployed for industrial applications?

A: This hydrotest pump is suitable for industrial sites, pipeline projects, manufacturing plants, and service centers across India where high-pressure equipment needs to be tested for leaks or structural integrity.Q: What is the process for setting up and operating the PressureJet pump?

A: Install the pump on a stable base, connect the BSPF inlet and outlet to your testing setup, and ensure the power supply is properly configured. Once connections are secured, fill the system with water and operate the electric motor to begin pressurizing the system.Q: Which industries benefit most from using this hydrotest pump?

A: Industries involved in oil and gas pipeline installations, manufacturing of pressure vessels, maintenance of steam coils, and production or testing of cylinders benefit greatly from this pump's high-pressure capabilities.Q: How does the Teflon-based high-pressure seal improve the pump's performance?

A: The special Teflon-based seal ensures excellent resistance against water leakage, even under high-pressure conditions, thereby extending the pump's lifespan and maintaining consistent, efficient performance during repeated hydrostatic tests.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Hydro Test Pump Category

Hydrostatic Pressure Testing Pump

Price 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Weight : Approx weight of bare pump: 85 Kilograms (kg)

Theory : Reciprocating Pump

Structure : Piston Pump

Usage : Water, Other

Motorized Hydro Test Pump

Price 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Weight : 170 Kilograms (kg)

Theory : Reciprocating Pump

Structure : Piston Pump

Usage : Water, Automobile, Other

Stainless Steel Hydro Test Pump

Price 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Weight : 120 Kilograms (kg)

Theory : Reciprocating Pump

Structure : Piston Pump

Usage : Water, Automobile, Other

Triplex Plunger Hydro Test Pump

Price 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Weight : Approx weight of bare pump: 85 Kilograms (kg)

Theory : Reciprocating Pump

Structure : Piston Pump

Usage : Water, Automobile, Other

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS